DEVICE REPLICATION AND ASSEMBLY

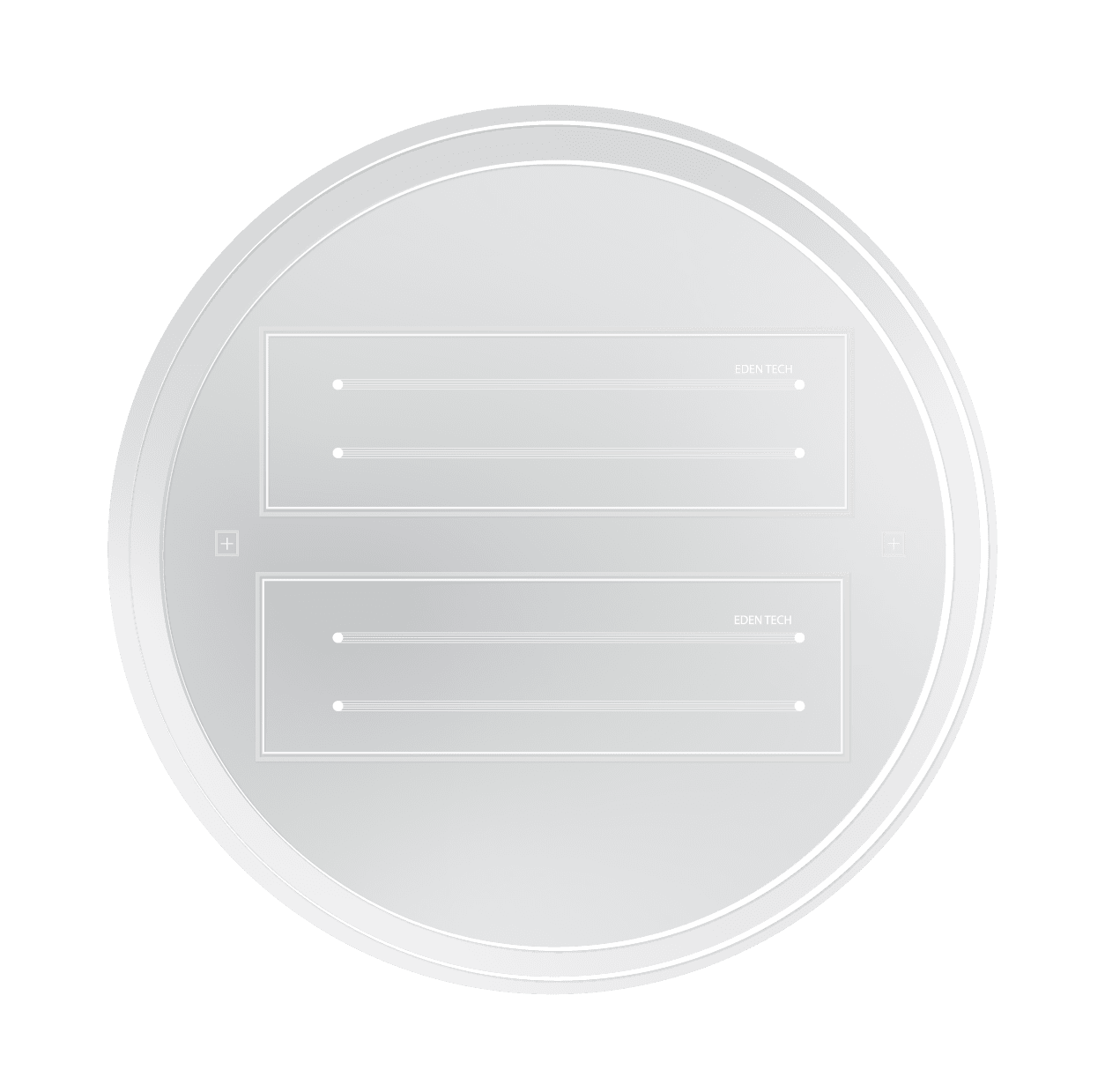

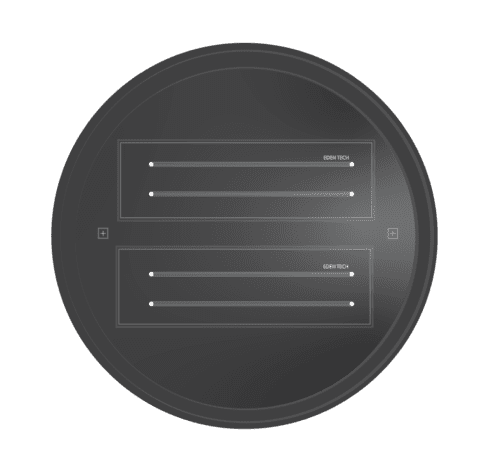

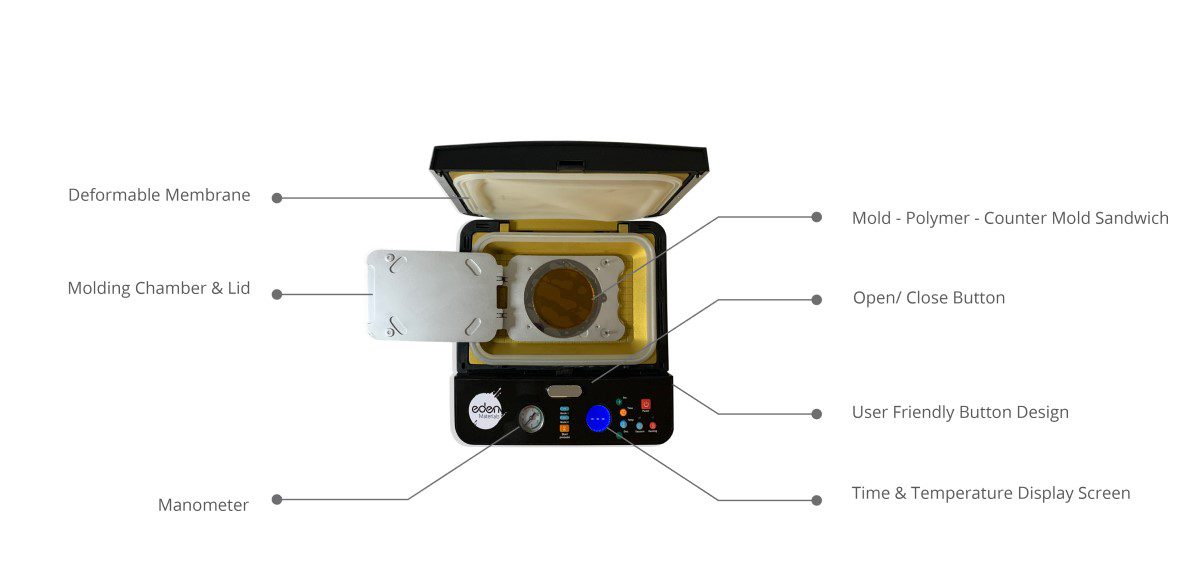

SUBLYM HOT EMBOSSING MACHINE

The Sublym hot embossing machine is the first portable plug-&-play hot embossing machine on the market. It is also dramatically cheaper than classic hot embossing machines priced in the range of hundreds of thousands of dollars.

The Sublym vs. A Hot Press

Sublym Machine

Optimized for Flexdym molding in only 1-2 minutes!

Compact & User-friendly design that requires little to no training.

Dramatically cheaper than most standard clean room equipment. This small investment is an opportunity for you to begin exploring microfluidics. Read more

CLASSIC HOT PRESS

Not optimized for Flexdym molding, therefore longer molding time.

Less easy-to-use alternative for the Sublym.

Slightly more expensive than the Sublym100, but a standard piece of equipment which is generally installed in fabrication facilities.

Eden Tech Youtube Channel

Videos & tips demonstrating how easy it is to to use all our products! Find step-by-step explanations on a variety of topics including:

Flexdym Bonding

Flexdym Molding

Flexdym 3D Printing

Sublym for Thermoplastics

Sublym Program Setup

Epoxym kit steps

and more…

different MOLDS FOR

Hot Embossing

Epoxy Resin Mold

One of the the best options for hot embossing, remains robust through repeated molding cycles. Our Epoxym kit enables the fabrication of epoxy mold replicas from Silicon wafers. Read more

Glass Mold

Etched glass molds are another robust option for hot embossing.

Metal Mold

Metal molds, such as those made from aluminium, are a robust option.

Silicon Wafer

The least ideal option for hot embossing are SU-8 & silicon wafers, due to their fragility and ease of breakage. However, when carefully handled and coated with non-stick spray, they may do the trick.

About Us

Eden Tech is a company reinventing microfluidics with user-friendly and scalable solutions. Our products are aimed at pushing forward both academic and industrial innovation.

Contact Us

device replication and assembly

SUBLYM HOT

EMBOSSING MACHINE

The Sublym hot embossing machine is the first portable plug-&-play hot embossing machine on the market. It is also dramatically cheaper than classic hot embossing machines priced in the range of hundreds of thousands of dollars.

Sublym Hot Embossing Machine

The Sublym vs. A Hot Press

Sublym Machine

Optimized for Flexdym molding in only 1-2 minutes!

Compact & User-friendly design that requires little to no training.

Dramatically cheaper than most standard clean room equipment. This small investment is an opportunity for you to begin exploring microfluidics. Read more

Classic Hot Press

Not optimized for Flexdym molding, therefore longer molding time.

Less easy-to-use alternative for the Sublym.

Slightly more expensive than the Sublym100, but a standard piece of equipment which is generally installed in fabrication facilities.

Eden Tech Youtube Channel

Videos & tips demonstrating how easy it is to to use all our products! Find step-by-step explanations on a variety of topics including:

Flexdym Bonding

Flexdym Molding

Flexdym 3D Printing

Sublym for Thermoplastics

Sublym Program Setup

Epoxym kit steps

and more…

Sublym Molding Protocol

different MOLDS FOR

Hot Embossing

Epoxy Resin Mold

One of the the best options for hot embossing, remains robust through repeated molding cycles. Our Epoxym kit enables the fabrication of epoxy mold replicas from Silicon wafers. Read more

Glass Mold

Etched glass molds are another robust option for hot embossing.

Metal Mold

Metal molds, such as those made from aluminium, are a robust option.

Silicon Wafer

The least ideal option for hot embossing are SU-8 & silicon wafers, due to their fragility and ease of breakage. However, when carefully handled and coated with non-stick spray, they may do the trick.

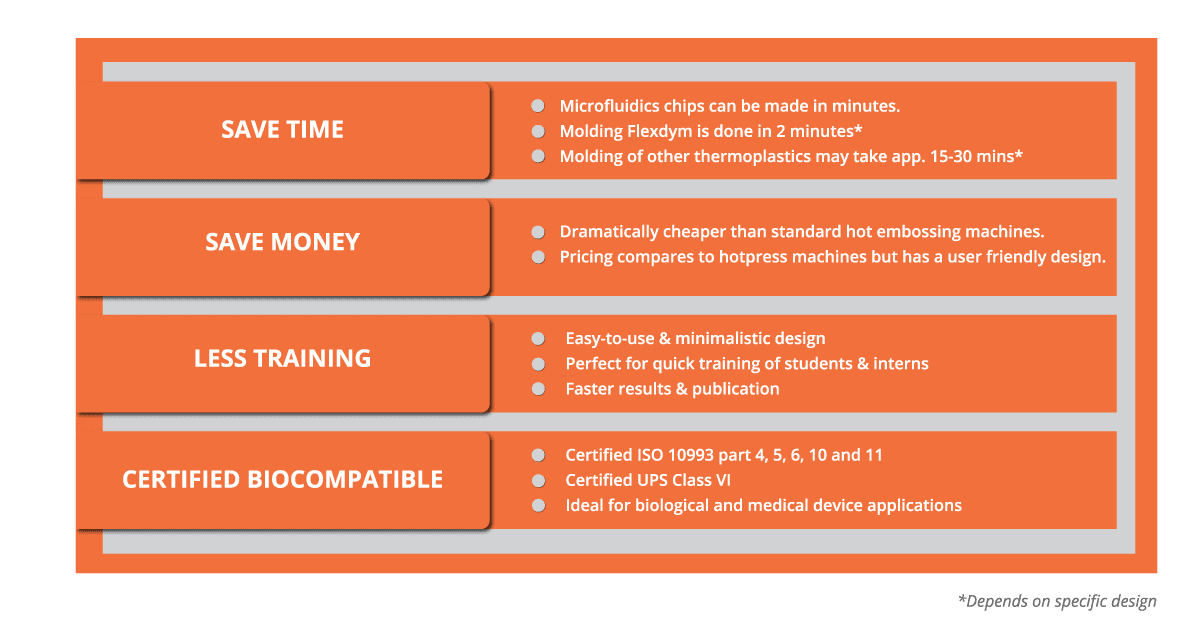

Sublym Advantages for Academic Research

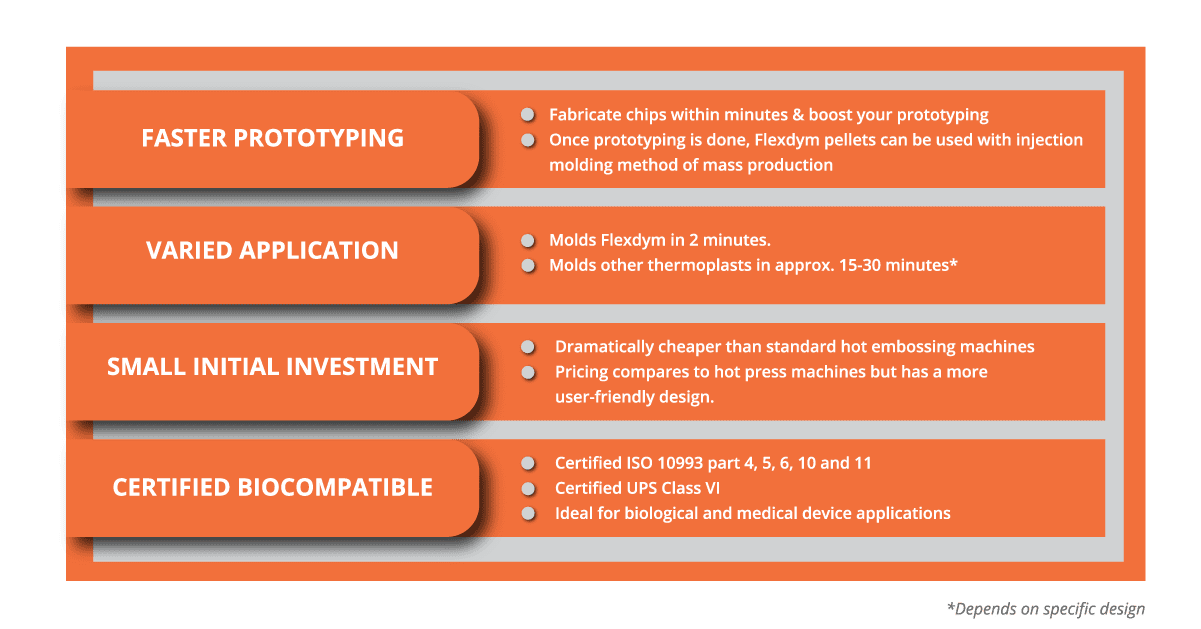

Sublym Advantages for Industry

Who Are Sublym Users?

They trust us

How sublym Kit Shipping works

Order

The product is available to pre-order at four week time increments.

Production

After this time, the orders will start to be produced during a two week period, and new orders will be added to the same shipment while stock is available.

Shipment

At this stage, items are shipped, usually taking a few working days to arrive, depending on client location.

Brochures & Documents

Flexdym is our original and patented material, developed by our CEO Emmanuel Roy. Unlike other materials used in microfluidics device fabrication, Flexdym is the first material created specifically for microfluidics biomedical applications. Our Sublym hot embossing machine was then created to render device replication fast and easy. It is compact, user-friendly and affordable. Finally, our Epoxym kit produces robust mold replicas from silicon wafer molds. For more information on any of these products, check out our brochures below.

Scientific Publications

Flexdym users worldwide are publishing their microfluidics research in top peer reviewed journals including, Nature, Advanced Materials, Analytical Chemistry, Lab on Chip and more. The topics also vary from cell culture and point of care diagnostics, to flexible electronics, wearable devices and micromixers. For a copy of our publications contatc us below!

About Us

Eden Tech is a company reinventing microfluidics with user-friendly and scalable solutions. Our products are aimed at pushing forward both academic and industrial innovation.