device replication and assembly

FLEXDYM BIOCOMPATIBLE MATERIAL

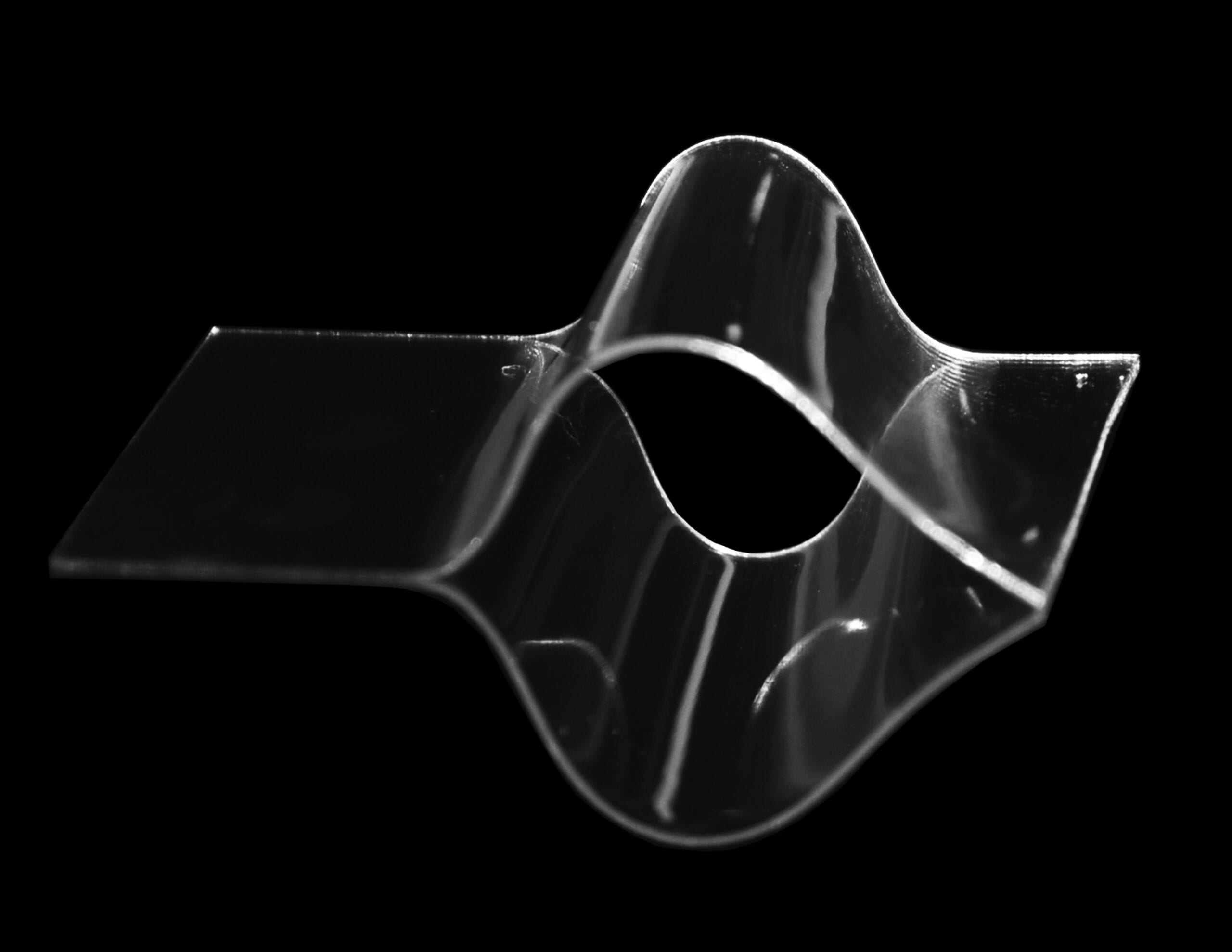

Flexdym is the first material specifically tailored for micro-fluidics biological applications. It is flexible, easily molded and bonded, transparent, and resistant to the adsorption of small particles.

STARTER PACK

FLEXDYM BIOCOMPATIBLE MATERIAL

The Sublym hot embossing machine is the first portable plug-&-play hot embossing machine on the market. It is also dramatically cheaper than classic hot embossing machines priced in the range of hundreds of thousands of dollars.

Flexdym Starter Pack - Alternative To PDMS

Flexdym™ Starter Pack – Alternative to PDMS

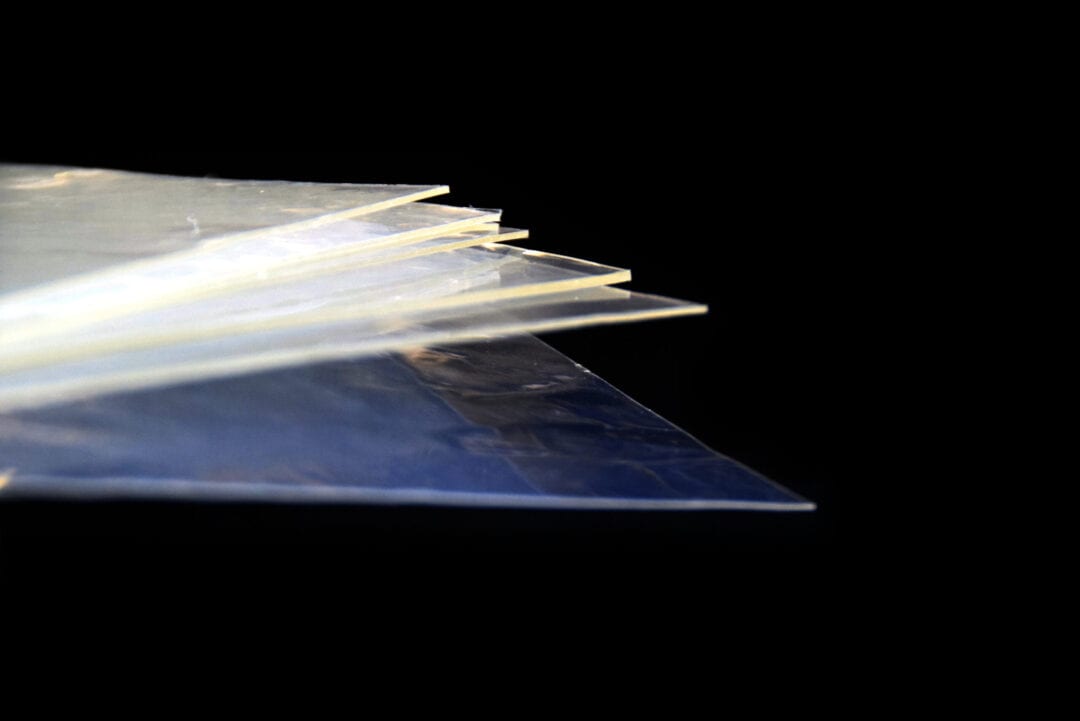

The Flexdym starter pack is great for first time users. Each pack contains 10 sheets of 15 x 15 cm Flexdym sheets, which can be selected from any one of our 4 thicknesses: 250 µm, 750 µm, 1200 µm and 2000 µm. And different thicknesses can be mixed in one pack!

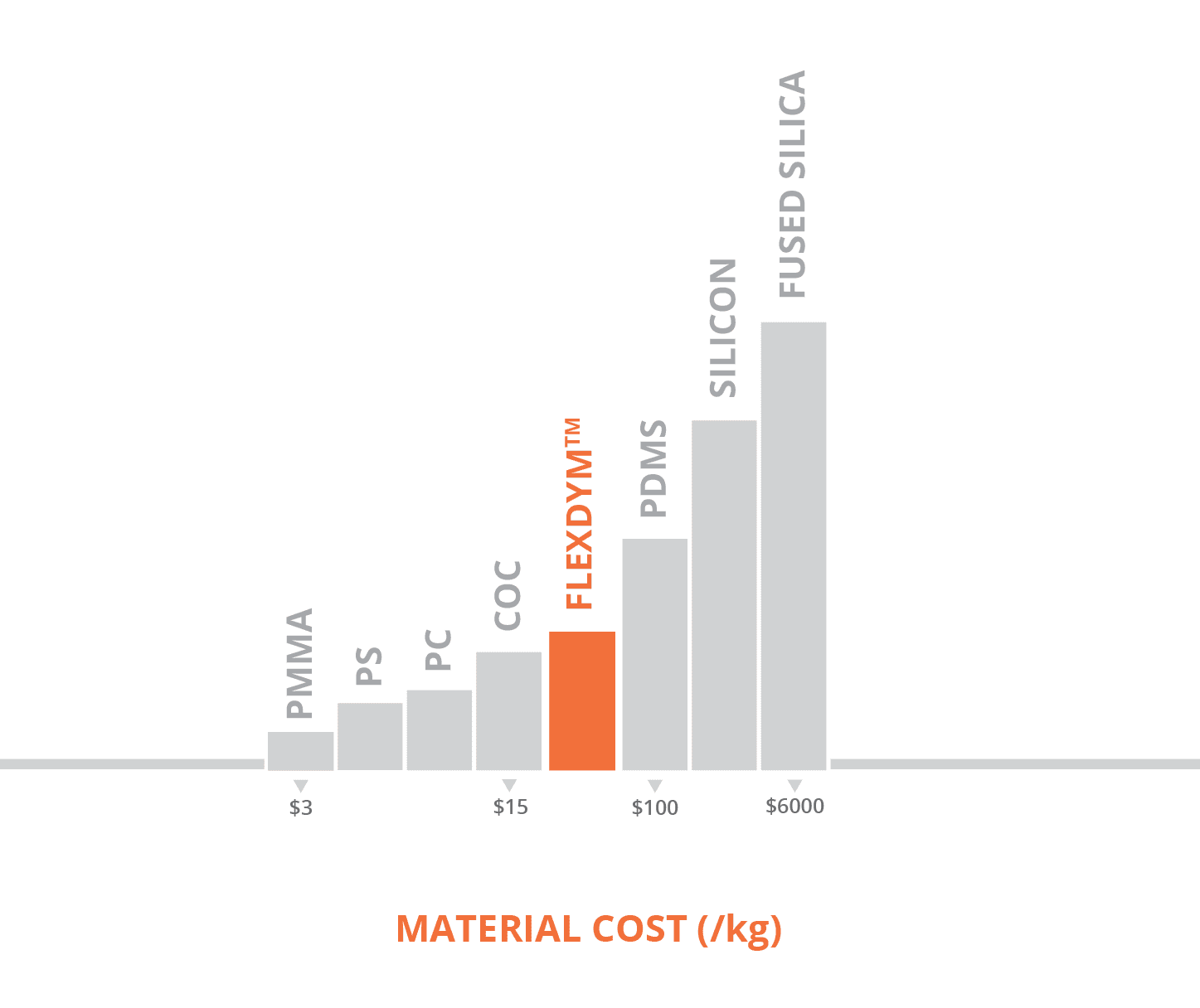

Are you looking for an alternative to PDMS soft-lithography for your microfluidics applications? The Flexdym™ polymer is the best alternative to PDMS and the first material specifically tailored for microfluidics chip fabrication. Why? Because most materials used in microfluidics have been repurpose from microelectronics and may not possess the best properties for biomedical applications. On contrast, Flexdym™ was developed and patented by our CEO and founder Emmanuel Roy specifically for biotechnology, while he worked at the CNRC (Canadian National Research Council) developing a point of care diagnostics device.

Therefore, Flexdym™ possesses the key material properties required for microfluidic biotech applications. Firstly, Flexdym™ is certified biocompatible according to international codes ISO 10993 (parts 4, 5, 6, 10, 11) and UPS Class VI. So that you can use it for the most important biological applications, such as organ-on-chip and point of care diagnostics. But this wouldn’t be enough. So we also made sure Flexdym™ has optical transparency, low molecular sorption properties and reduced gas permeability.

Flexdym™ is a block co-polymer that combines the best of elastomers (e.g. PDMS) and thermoplastics. Read our latest blog article describing the chemical composition of Flexdym and the bonding mechanisms which make it so fast and easy to assemble Flexdym™ devices. Flexdym™ can bond to a variety of substrates including glass, silicon, COC, COP, PS, PC, and PMMA. This provides a large range of versatility, according to the application at hand. The bonding strength varies according to the substrate (see table below), providing the option over reversible and permanent bonding. For this reason, Flexdym™ serves as an excellent option for wearable microfluidic devices, or for reversible sealing of microfluidic cartridges.

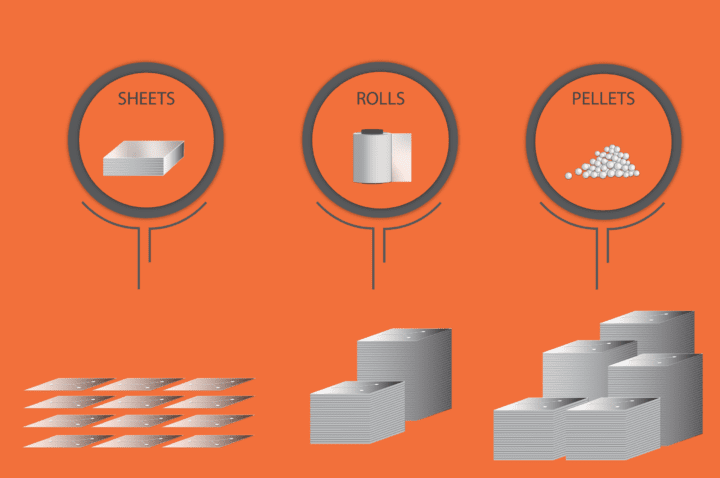

Another major advantage of Flexdym™ as an alternative to PDMS, is that it can be used in the scale up of microfluidics devices for commercial or industrial purposes. The starter pack is the perfect format for first-time Flexdym users to test the material for their application. In one starter pack different thicknesses can be mixed, making the selection process easier for you! Once you have discovered your thickness of choice, the next step is to scale-up with our more cost effective formats, linked here: Flexdym™ Rolls or Flexdym™ Pellets.

Remember you can follow Eden Tech on Linkedin and Youtube for all the latest Flexdym™ news!

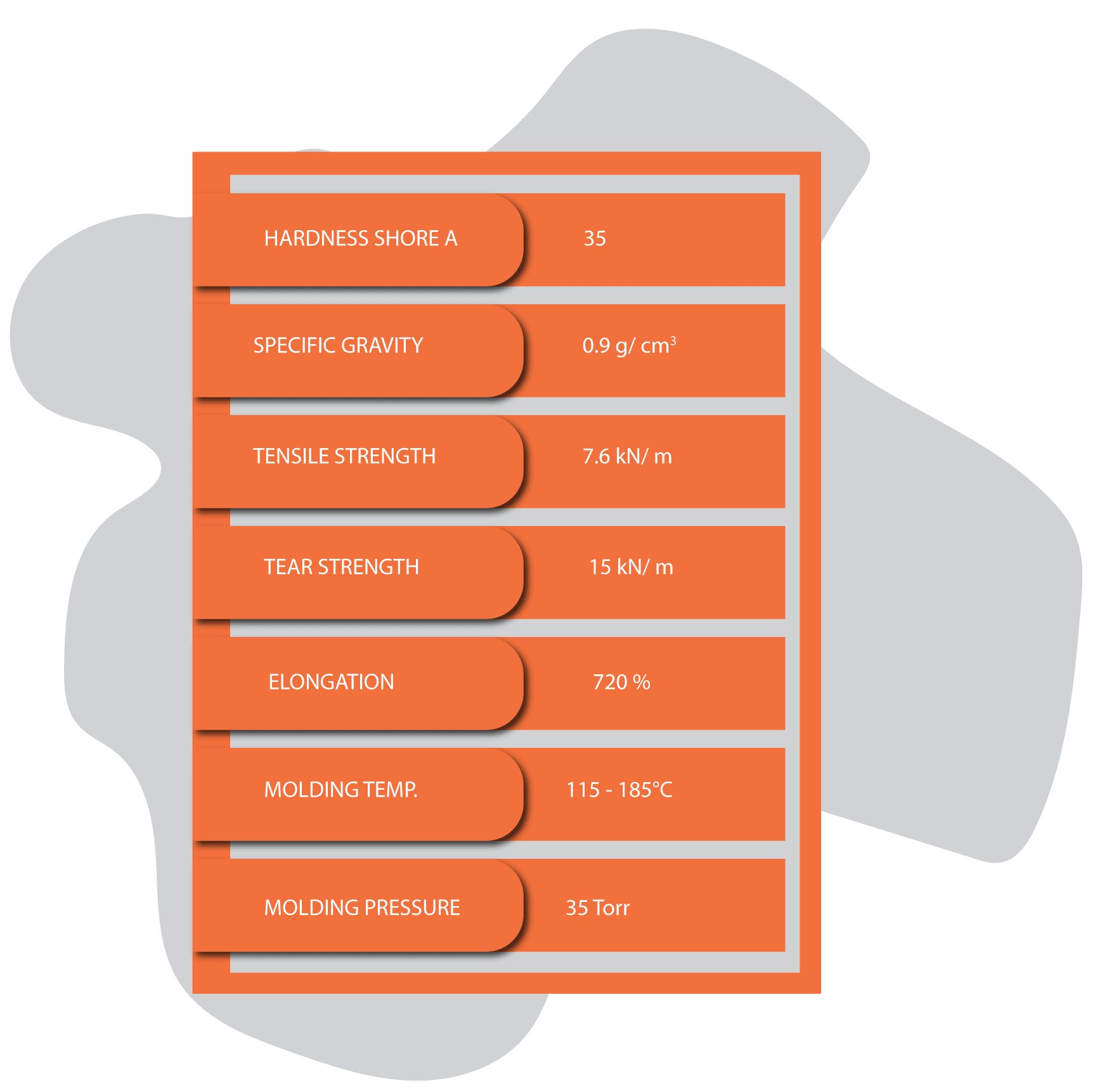

| Thickness | 250µm, 750µm, 1200µm, 2000µm, Mixed Pack |

|---|---|

| Size | 15 cm x 15 cm |

| Hardness Shore A | 35 |

| Specific gravity | 0.9 g/cm3 |

| Tear strength | 15 kN/m |

| Tensile strength | 7.6 kN/m |

| Elongation | 720% |

| Molding temperature | 115 – 185 °C |

| Molding pressure | 35 Torr |

Create Flexdym Microfluidic Devices in Minutes

Looking to Test Out Flexdym?

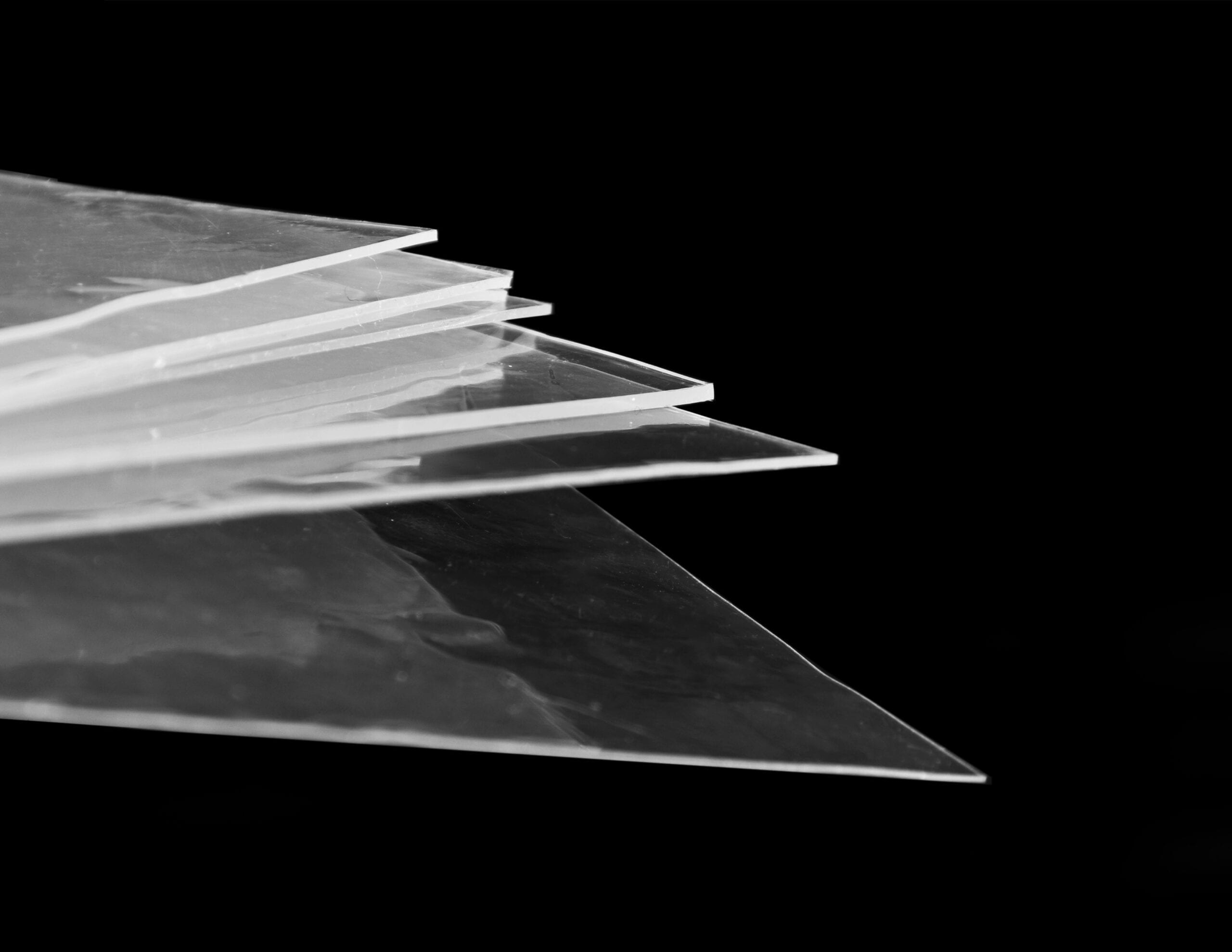

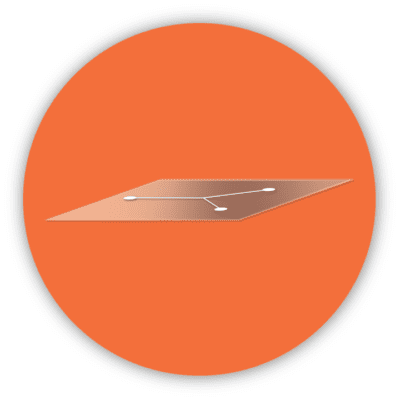

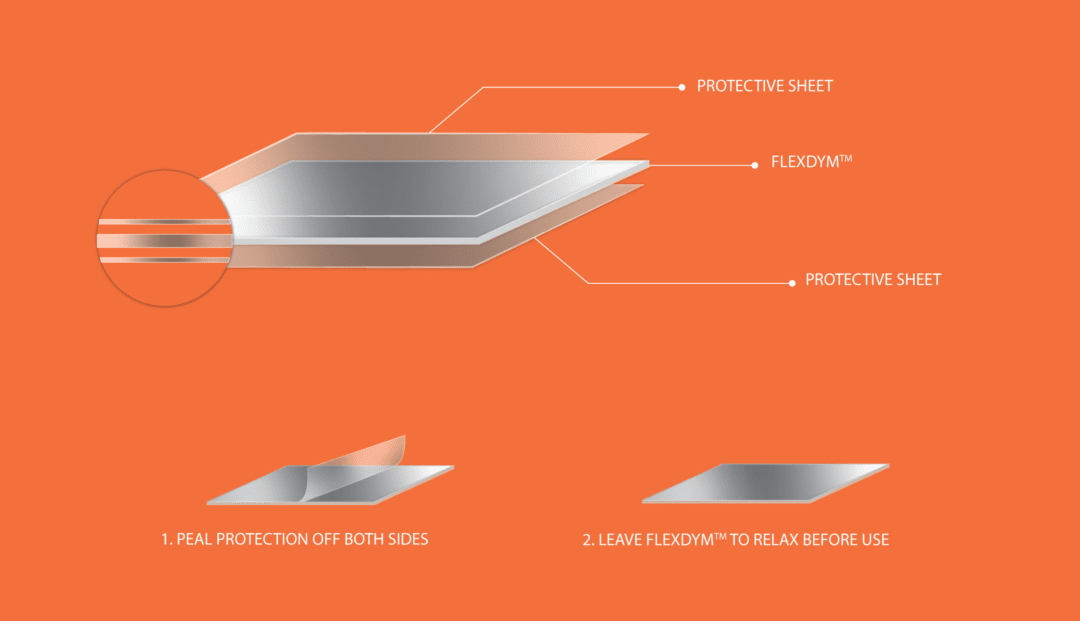

The starter pack contains 10 sheets of 15 x 15 cm Flexdym, wrapped in 2 protective transparent films.

In one pack choose between a range of thicknesses: 0.25, 0.75, 1.2, or 2 mm. Mix these according to your preference.

Each sheet can be cut using scissors & molded using a hot press. Depending on the size of the mold, the process can last from 30 s to 15 min.

Flexdym Handling

A Flexdym sheet is protected with films on either side, to avoid contamination of the material. Keep the protective films on the sheet when cutting (using scissors or die cut). Remove the films once you are ready to sandwich your Flexdym sheet between the mold and counter mold.

Easy Steps for

Flexdym Microfluidic Devices

01

CUT IT

Cut a protected Flexdym sheet using scissors, cutters, hot knives, die cuts, lasers, etc. The material is ready to use, with no mixing or curing steps needed.

02

PRESS IT

Remove protective films & place Flexdym sheet between a smooth counter mold and your mold. Then apply pressure using a hot press, hot embossing machine, or other heat-pressure combination.

03

CREATE INLETS

Place protective films on molded Flexdym sheets and punch inlet & outlet ports for reagent entry and exit.

04

PLACE IT

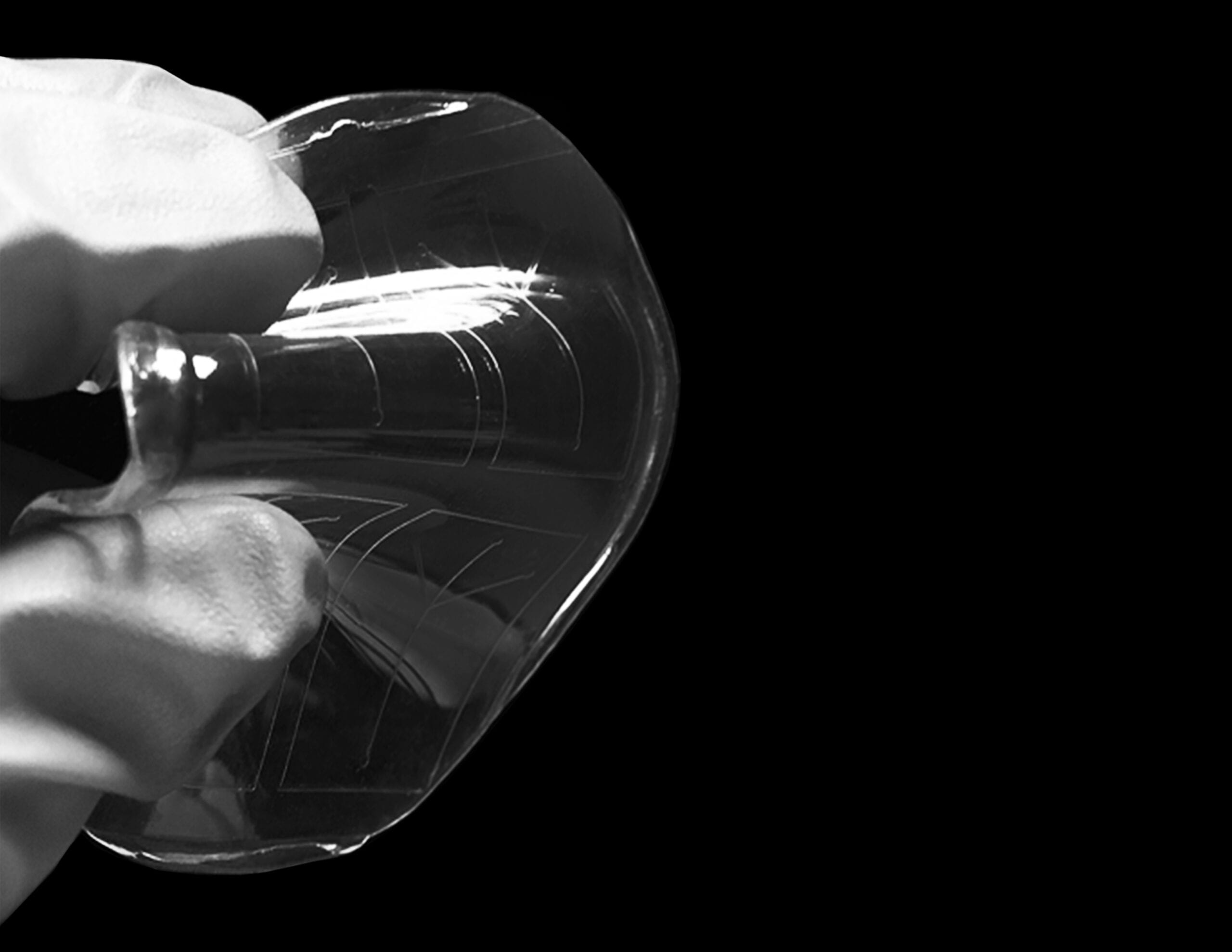

Remove protective sheet from molded side of Flexdym sheet and place on selected substrate. Flexdym's soft material properties help provide good conformal contact between the two surfaces. Flexdym can be assembled with various thermoplastics, glass & silicon.

A Biocompatible Material that is Scalable.

From Prototyping...

Use Flexdym starter packs or rolls to create chips quickly and easily. Mold Flexdym in as little as 30 seconds using our Sublym machine. The full Flexdym protocol length is approx. 15-20 minutes, depending on mold design, mold material, feature resolution, design size, etc.

...to Mass Production.

The Flexdym pellets are compatible with 3D printing and injection molding processes used in mass production. Flexdym sheets can also be used to mass produce devices via roll-to-roll embossing. Now you have the opportunity to turn you technology into a commercial product.

Flexdym Device Replication:

Sublym Machine vs. Hot Press

Eden Tech’s mission is to create user-friendly microfabrication solutions to help researchers boost chip production. With the creation of Flexdym, it was important to offer an affordable machine to mold the material.

Flexdym’s thermoplastic properties means it can be molded via hot embossing, just like other thermoplastics (e.g. COC, polystyrene, or polycarbonate). Hot embossing involves utilizing pressure, heat and time to transfer features from the mold to the material. Hot embossing is a great alternative to casting and soft-lithography methods of microfabrication.

The Sublym vs. A Hot Press

Sublym Machine

Optimized for Flexdym molding in only 1-2 minutes!

Compact & User-friendly design that requires little to no training.

Dramatically cheaper than most standard clean room equipment. This small investment is an opportunity for you to begin exploring microfluidics. Read more

Classic Hot Press

Not optimized for Flexdym molding, therefore longer molding time.

Less easy-to-use alternative for the Sublym.

Slightly more expensive than the Sublym100, but a standard piece of equipment which is generally installed in fabrication facilities.

The Sublym vs. A Hot Press

Sublym Machine

Optimized for Flexdym molding in only 1-2 minutes!

Compact & User-friendly design that requires little to no training.

Dramatically cheaper than most standard clean room equipment. This small investment is an opportunity for you to begin exploring microfluidics. Read more

CLASSIC HOT PRESS

Not optimized for Flexdym molding, therefore longer molding time.

Less easy-to-use alternative for the Sublym.

Slightly more expensive than the Sublym100, but a standard piece of equipment which is generally installed in fabrication facilities.

Molds For Hot Embossing

Epoxy Resin Mold

Epoxy resin molds are one of the best options for hot embossing. They remain robust through repeated molding cycles. Our Epoxym kit enables the fabrication of epoxy mold replicas from Silicon wafers.

Glass Mold

Etched glass molds are another robust option for hot embossing. For rapid and easy design optimization, we also recommend hybrid SU-8 dry film & glass molds.

Metal Mold

Metal molds, such as those made from aluminium, are another robust option.

Silicon Wafer

The least ideal option for hot embossing are SU-8 & silicon wafers, due to their fragility and ease of breakage. However, when carefully handled and coated with non-stick spray, they do the trick. Check out our molding video.

Eden Tech has optimized Flexdym’s pricing to be comparable to other widely used materials in microfluidics, with added advantages:

Biocompatible

Transparent

Scalable

User-Friendly

Gas Permeability of Flexdym

We have conducted gas permeability tests for 2 mm of Flexdym at 23°C, 50% RH. These results combined with those of other Flexdym users, show a range of 40 to 70-fold lower gas permeability for Flexdym compared to PDMS. However, cell culture remains a top application of Flexdym. For published results, contact us.

|

PERMEABILITY

|

FLEXDYM RESULTS

|

|---|---|

|

Oxygen

|

7.86 Barrer

|

|

Carbon dioxide

|

15.99 Barrer

|

Resistance to Solvents

Similarly to PDMS and other thermoplastic materials used in microfluidic device fabrication, Flexdym TM is resistant to commonly used solvents such as acids and bases, as well as methanol/ethanol. It is resistant to fluorinated oils, commonly used in droplet based microfluidic applications. Also like these other materials, results show it swells in the presence of carboxylic acid and other oils. It may be important to note, it is not resistant to hydrocarbons. To find out more about Flexdym material chemistry read our news article.

|

CHEMICAL

|

RESISTANCE

|

|---|---|

|

Acids

|

R

|

|

Bases

|

R

|

|

Fluorinated Oils

|

R

|

|

Methanol/ Ethanol

|

R

|

|

Carboxylic Acid

|

Swell

|

|

Hydrocarbons

|

NR

|

|

Oil

|

Swell

|

Versatility: Flexdym Bonding Strength

Flexdym combines the best properties of elastomers, like PDMS, and thermoplastics, like COC, polystyrene or polycarbonate. Flexdym acheives this through its block co-polymer structure composed of styrenic hard blocks and ethylene-butylene soft blocks, which allow it to remain soft, yet compatible with hot embossing.

Flexdym acts as a pressure sensitive and slow adhesive, bonding with a selection of substrates through conformal contact. Flexdym bonding is accomplished through manual lamination or standardized through the use of a press. See our bonding video.

Flexdym can be recycled and reused. Simply wash or sterilize the molded material (e.g. via gamma treatment) and re-mold.

Finally, Flexdym has tunable bonding strength, which varies according to the material selected as a substrate. Flexdym bonding has been tested for the range of thermoplastic substrates below: PS, PC, PI, PMMA, COC and COP. It can also bond to glass and silicon.

|

POLYMER

|

GRADE

|

COMPANY

|

THICKNESS (mm)

|

|---|---|---|---|

|

Polystyrene (PS)

|

Crystal Polystyrene

|

Eloise

|

1

|

|

Polycarbonate (PC)

|

Lexan *8040

|

Sabic

|

0.175

|

|

Polyimide (PI)

|

Kapton HN

|

Fralock

|

0.125

|

|

Polyimide (PI)

|

Crilex

|

Fralock

|

1

|

|

PMMA

|

Acrylite H12

|

Eloise

|

1

|

|

COC

|

Europlex COC 99304

|

Topas

|

1

|

|

COP

|

ZenorFilm TM

|

-

|

0.1

|

|

BONDING STRENGTHS TESTED

|

|

|---|---|

|

Flexdym

|

8 bars

|

|

Glass

|

700 mbars

|

|

COC

|

2 bars

|

|

COP

|

2 bars

|

|

PC

|

2 bars

|

|

PMMA

|

2 bars

|

|

Polyimide

|

2 bars

|

Top Flexdym Applications Right Now

Cell Culture

Flexdym has low sorption properties & high gas permeability.

POC Cartridges

Flexdym can bond reversibly to a variety of materials, acting as a excellent seal.

Valves

Flexdym has soft elastomeric properties & high elongation.

Wearable Device

Flexdym is a pressure sensitive adhesive that naturally sticks to the skin.

Flexdym for Cell Study Devices

- Certified Biocompatible ISO 10993 parts 4, 5, 6, 10 & 11 AND USP Class VI.

- Good cell adhesion & proliferation over long time periods.

- Bonding to PS, glass and other commonly used cell culture materials.

- Good bonding strength up to several bars, withstands 37°C humidity conditions.

- Stable hydrophilicity post plasma treatment.

- Gas permeable, but low sorption of small molecules.

Request Publications:

Flexdym For Diagnostic Devices

- Certified Biocompatible ISO 10993 parts 4, 5, 6, 10 & 11 AND USP Class VI.

- Optical transparency, with UV-Vis trasnmittance over 295-800 nm.

- Material cost optimization, ideal for POC cassettes & cartridges.

- Withstands thermocycling temperatures for PCR and others amplification reactions.

- Functionalization similar to other SEBS, via amino-based, EDC/NHS coupling & silane-based chemistry.

- Resistant to fluorinated oils, ethanol, acids & bases.

Request Publications:

Flexdym Mechanical Properties.

Flexdym combines properties of thermoplastics and elastomers. This explains it’s elasticity (Young Modulus of 1.15 MPa) and simultaneous ability to be hot embossed.

Who Are Flexdym Users?

What Flexdym Users Say...

Eden Materials Flexdym Clients...

Flexdym Brochures & Documents

Flexdym is our original and patented material, developed by our CEO Emmanuel Roy. Unlike other materials used in microfluidics device fabrication, Flexdym is the first material created specifically for microfluidics biomedical applications. Our Sublym hot embossing machine was then created to render device replication fast and easy. It is compact, user-friendly and affordable. Finally, our Epoxym kit produces robust mold replicas from silicon wafer molds. For more information on any of these products, check out our brochures below.

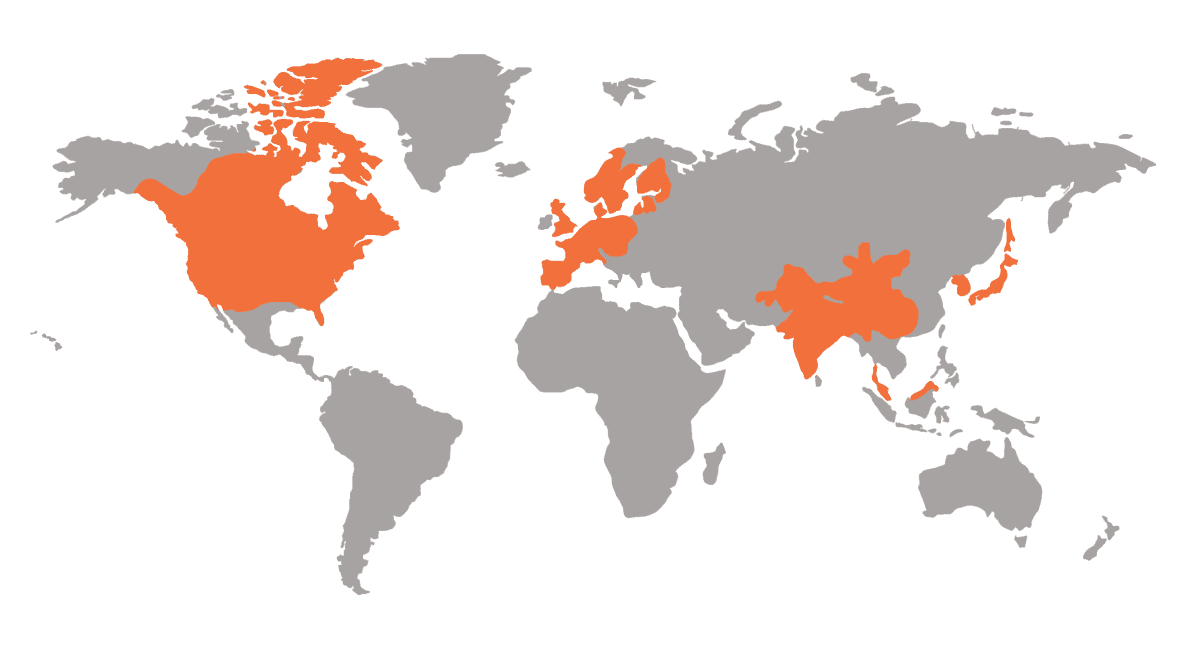

Flex Users Worldwide

The Flexdym user community is growing quickly and strongly. Today, Eden Tech has clietns all over the world over 4 different continents. We also have 2 distributors in the United States (Flowcell) and China (Youngchip).

Insightful Publications

Flexdym users worldwide are publishing their microfluidics research in top peer reviewed journals including, Nature, Advanced Materials, Analytical Chemistry, Lab on Chip and more. The topics also vary from cell culture and point of care diagnostics, to flexible electronics, wearable devices and micromixers. For a copy of our publications contatc us below!

Eden Tech

Headquarters:

11 Rue de Lourmel

Paris 75015, France

Client Facing Offices:

4 Rue de Rambervillers

Paris 75012, France

Eden Tech

Headquarters:

11 Rue de Lourmel

Paris 75015, France

Client Facing Offices:

4 Rue de Rambervillers

Paris 75012, France

The Licensee shall also mark all Products with labels containing the following language: Thermoplastic materials, Flexdym, Flexaspin, Fluoroflex, are sold under license to US patents 9,238,346 and 10,369,566 and CA patent 2,681,897 from the National Research Council Canada. Rights to use these products are limited to research uses only and are not to be used for any other purpose, such as but not limited to, commercial uses, in vitro diagnostic uses, ex vivo or in vivo therapeutic uses or any type of unauthorized applications. No other rights are conveyed. Inquiry into the availability of a license to broader rights or the use of these thermoplastic materials for commercial purposes should be directed to National Research Council Canada. Purchase of these products does not grant rights to (1) offer the products or any derivatives thereof for resale; or (2) to distribute or transfer the products or any derivative thereof to third parties.

Trademark Flexdym and Sublym – EU.IP Offices.