MOLD REPLICATION UNIT

EPOXYM MOLD

SOLUTION

The Epoxym mold replication solution provides innovators at the initial stages of device development, with low-cost molds for routine device replication.

01

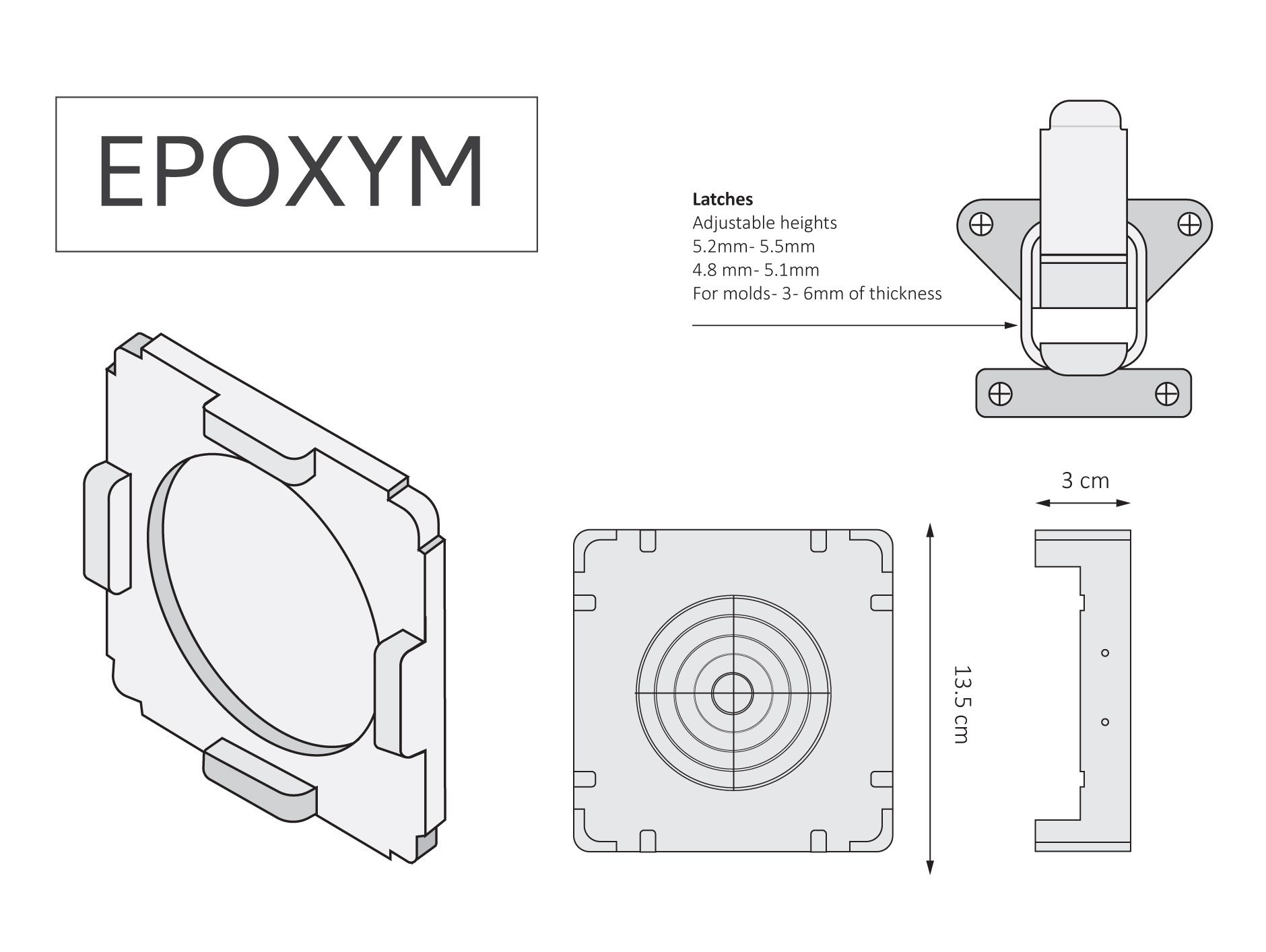

EPOXYM FRAME

Epoxym Kit Component

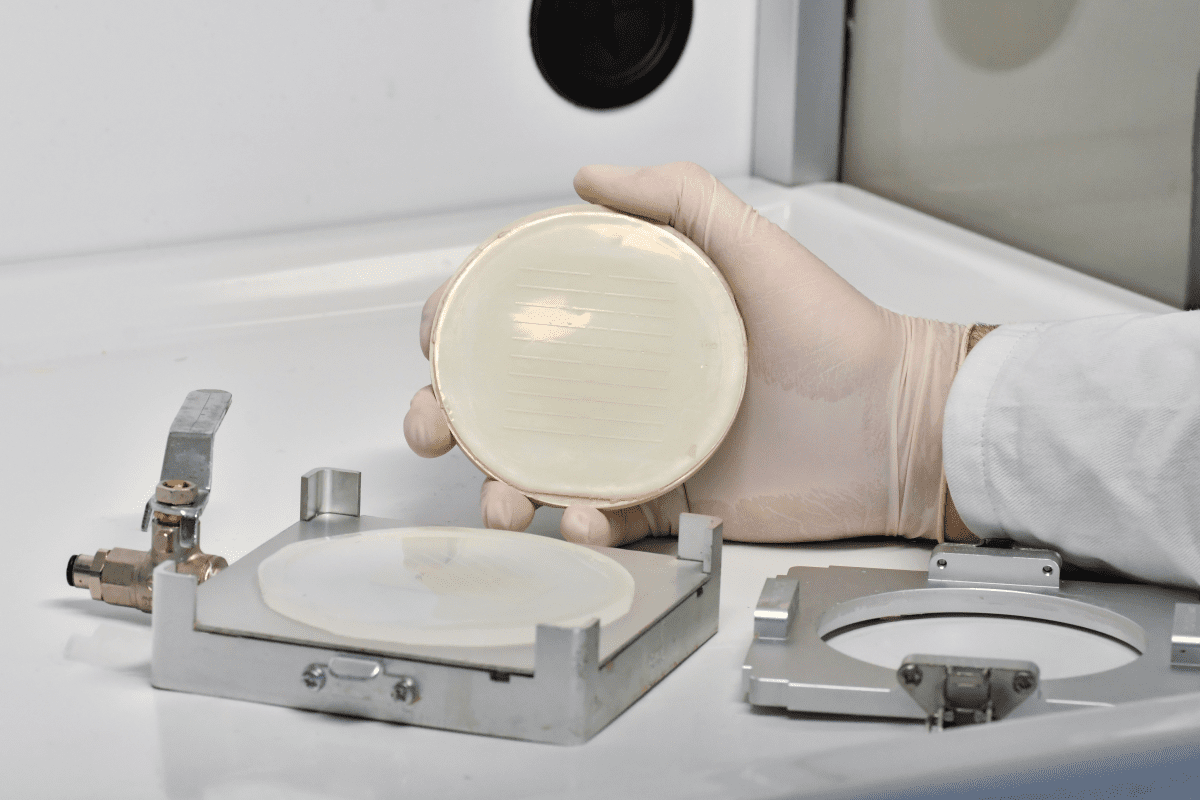

The mold frame is composed of two parts: the base/bottom of the frame and the lid of the frame. The base contains a small hole in its center, allowing for a vacuum seal to be created during the molding process. The vacuum can be controlled using a vacuum valve. The lid contains a large circle opening at its center, to enable casting of the mold. The entire system has an adaptor connecting the frame to the vacuum pump tubing.

02

EPOXY RESIN

Epoxym Kit Component

Create monolithic & mobust mold using our carefully selected epoxy resin. It has high replication fidelity (0.2 μm) and high temperature resistance (180°C).

EPOXYM KIT

COMPONENTS

FRAMES

LATCHES

RESIN

EPOXYM KIT

LATCH MECHANISM

EASY TO USE | ROBUST SEAL | CREATE UPTO FOUR INCHES MOLD SIZE

Advantages of Epoxym Resin Mold

- High temperature resistance

- Withstands high no of molding

- Robust than silicon wafers

- Saves time and money

Epoxym Kit 2-Step Protocol

SU - 8 & SILICON WAFER

Pattern is created using SU-8 and standard photolithography techniques.

PDMS Intermediate

PDMS is cast on the silicon SU-8 mastermold & baked.

FINAL EPOXY RESIN MOLD

Epoxym resin is poured on PDMS mold. Final Epoxym replica mold baked & ready.

Epoxym Kit Casting

- Easy to Mold

- Mess Free

- Quality Molds

- User friendly

Eden Tech Youtube Channel

Videos & tips demonstrating how easy it is to to use all our products! Find step-by-step explanations on a variety of topics including:

Flexdym Bonding

Flexdym Molding

Flexdym 3D Printing

Sublym for Thermoplastics

Sublym Program Setup

Epoxym kit steps

and more…

About Us

Eden Tech is a company reinventing microfluidics with user-friendly and scalable solutions. Our products are aimed at pushing forward both academic and industrial innovation.

Contact Us

MOLD REPLICATION UNIT

EPOXYM MOLD SOLUTION

The Epoxym mold replication solution provides innovators at the initial stages of device development, with low-cost molds for routine device replication.

01

EPOXYM FRAME

Epoxym Kit Component

The mold frame is composed of two parts: the base/bottom of the frame and the lid of the frame. The base contains a small hole in its center, allowing for a vacuum seal to be created during the molding process. The vacuum can be controlled using a vacuum valve. The lid contains a large circular opening at its center, to enable the casting of the mold. The entire system has an adaptor connecting the frame to the vacuum pump tubing.

02

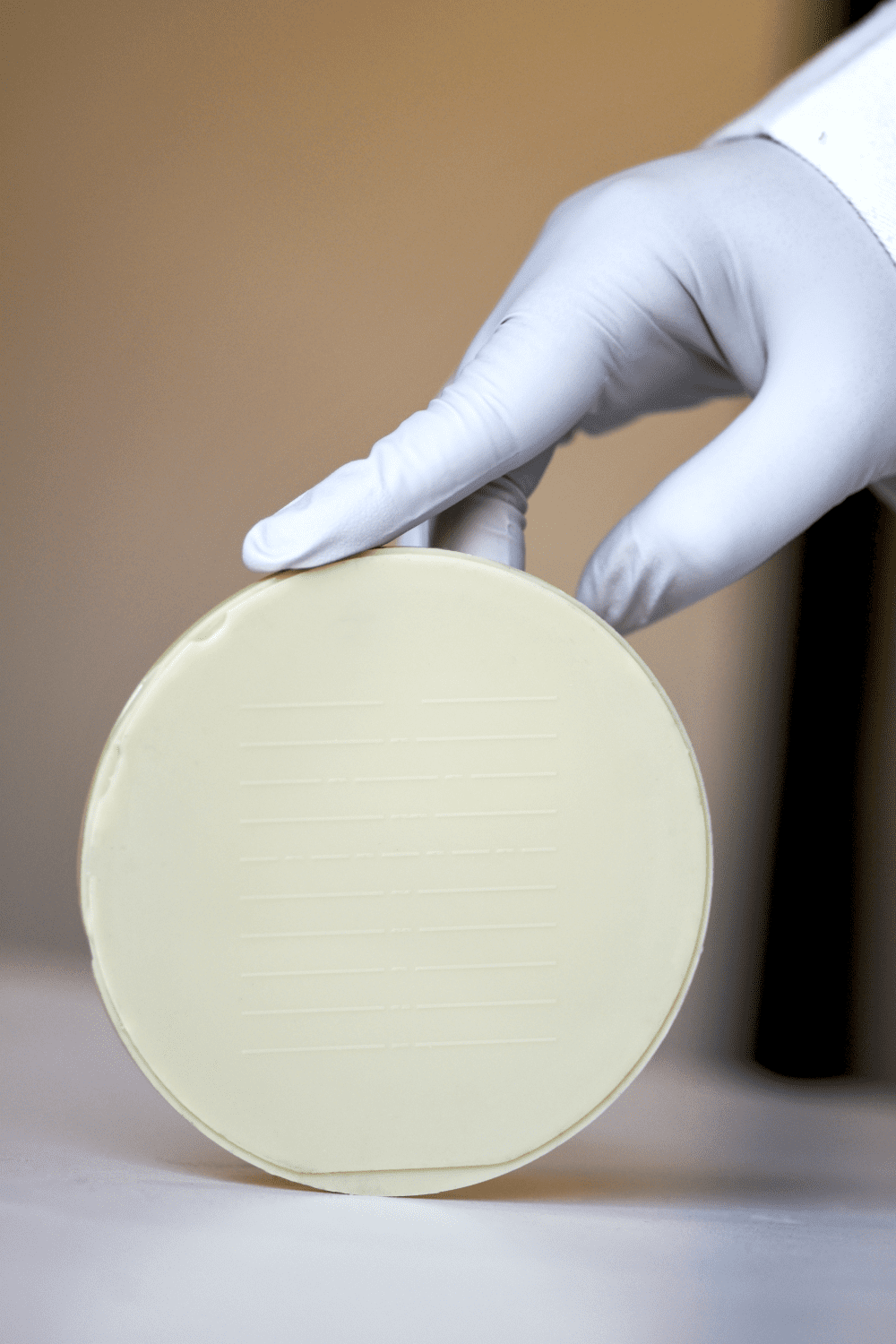

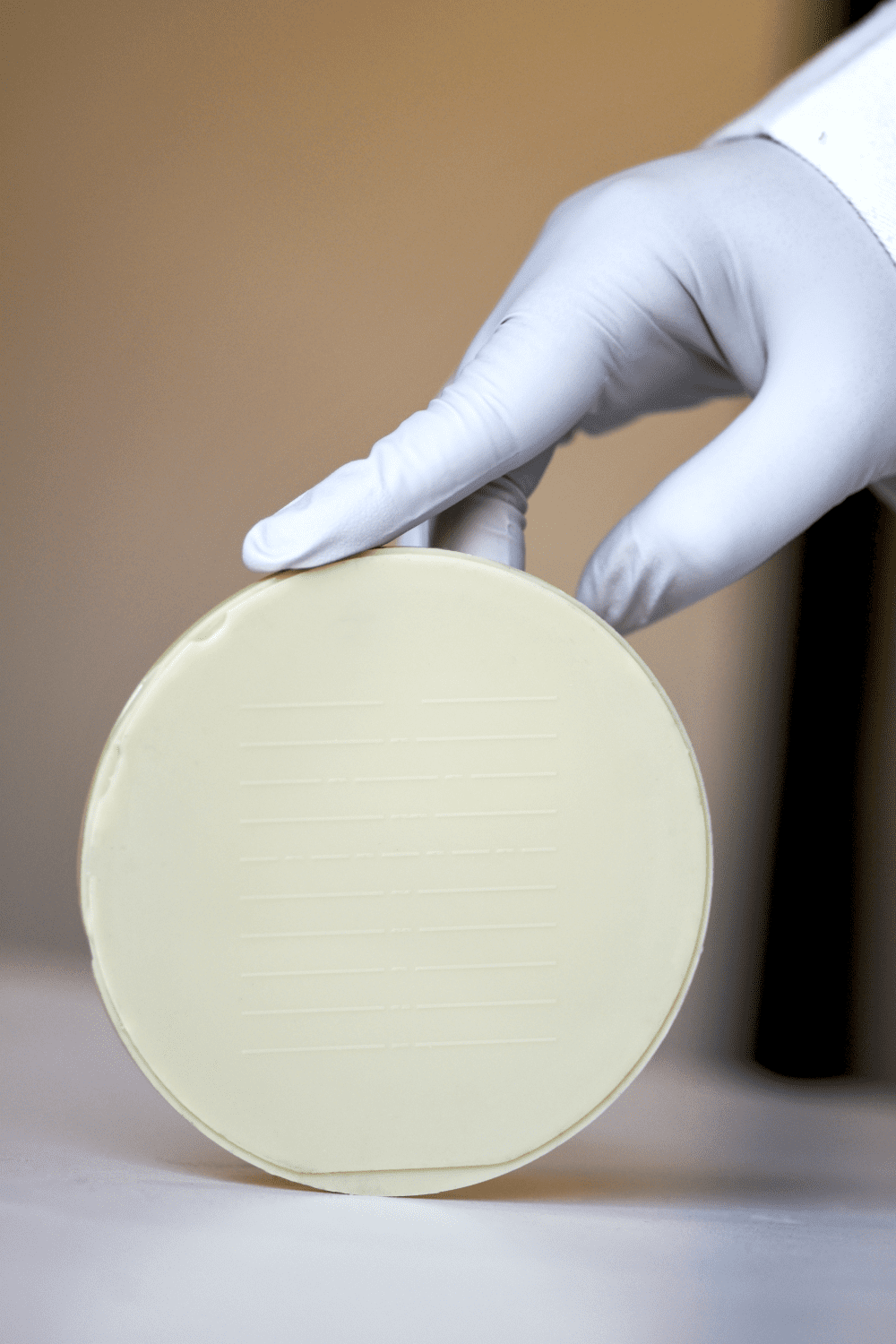

EPOXY RESIN

Epoxym Kit Component

Create a monolithic & robust mold using our carefully selected epoxy resin. It has high replication fidelity (0.2 μm) and high-temperature resistance (180°C).

EPOXYM KIT

KIT COMPONENTS

FRAME

LATCHES

EPOXY RESIN

Epoxym Kit : 2 Step Protocol

SU-8 & Silicon Wafer

PDMS Intermediate

PDMS is cast on the silicon SU-8 mastermold & baked.

Final Epoxy Resin Mold

EPOXYM KIT

LATCH MECHANISM

EPOXYM KIT

ADVANTAGES OF EPOXY MOLD

- High temperature resistance.

- Withstands high number of molding cycles

- More robust than silicon wafers

- Saves time and money

Eden Tech Youtube Channel

Videos & tips demonstrating how easy it is to to use all our products! Find step-by-step explanations on a variety of topics including:

Flexdym Bonding

Flexdym Molding

Flexdym 3D Printing

Sublym for Thermoplastics

Sublym Program Setup

Epoxym kit steps

and more…

Brochures & Documents

Flexdym is our original and patented material, developed by our CEO Emmanuel Roy. Unlike other materials used in microfluidics device fabrication, Flexdym is the first material created specifically for microfluidics biomedical applications. Our Sublym hot embossing machine was then created to render device replication fast and easy. It is compact, user-friendly and affordable. Finally, our Epoxym kit produces robust mold replicas from silicon wafer molds. For more information on any of these products, check out our brochures below.

About Us

Eden Tech is a company reinventing microfluidics with user-friendly and scalable solutions. Our products are aimed at pushing forward both academic and industrial innovation.