Microfluidics in 2025: Applications, Trends & How It Work

What Is Microfluidics?

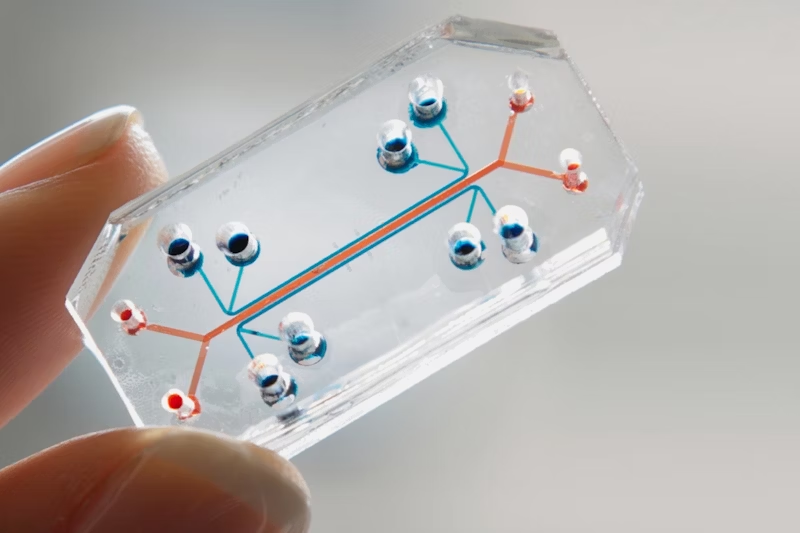

Microfluidics is the science and technology of manipulating small volumes of fluids typically in the microliter to picoliter range within channels less than 1 millimeter wide. It combines principles from physics, chemistry, biology, and engineering to create miniaturized systems capable of controlling, mixing, sorting, and analyzing fluids.

At its core, microfluidics enables the development of lab-on-a-chip devices that integrate multiple lab functions into a single, compact platform.

Why Microfluidics Matters in 2025

Microfluidic technology is driving innovation across healthcare, biotechnology, pharmaceuticals, and environmental monitoring. In 2025, it plays a critical role in:

Point-of-care diagnostics

Personalized medicine

Organ-on-chip research

High-throughput drug screening

Benefits of Microfluidics:

- Minimal reagent and sample consumption

- Faster analysis and processing times

- Portability and compact design

- High precision and reproducibility

- Integrated, automated workflows

A Brief History of Microfluidics

The microfluidics field was born in the 1980s with the development of MEMS (Micro-Electro-Mechanical Systems). The 1990s marked the emergence of lab-on-a-chip platforms. The adoption of PDMS-based soft lithography in the early 2000s made fabrication accessible to academic labs.

Today, cleanroom-free methods like 3D printing, hot embossing, and materials such as Flexdym™ are revolutionizing how microfluidic devices are designed and manufactured.

Key Principles of Microfluidics

Understanding fluid behavior at the microscale is essential for designing efficient microfluidic chips. Here are the foundational principles:

Laminar Flow: Fluids move in smooth layers (low Reynolds number), allowing precise control.

Diffusion-Based Mixing: Mixing occurs through molecular diffusion, not turbulence.

Capillarity & Surface Tension: Fluids can move without pumps using capillary action.

Electrokinetics: Voltage-driven flow, ideal for pump-less microfluidic systems.

Learn more about microfluidics in our blog article section.

Microfluidic Chips: Structure, Types & Design

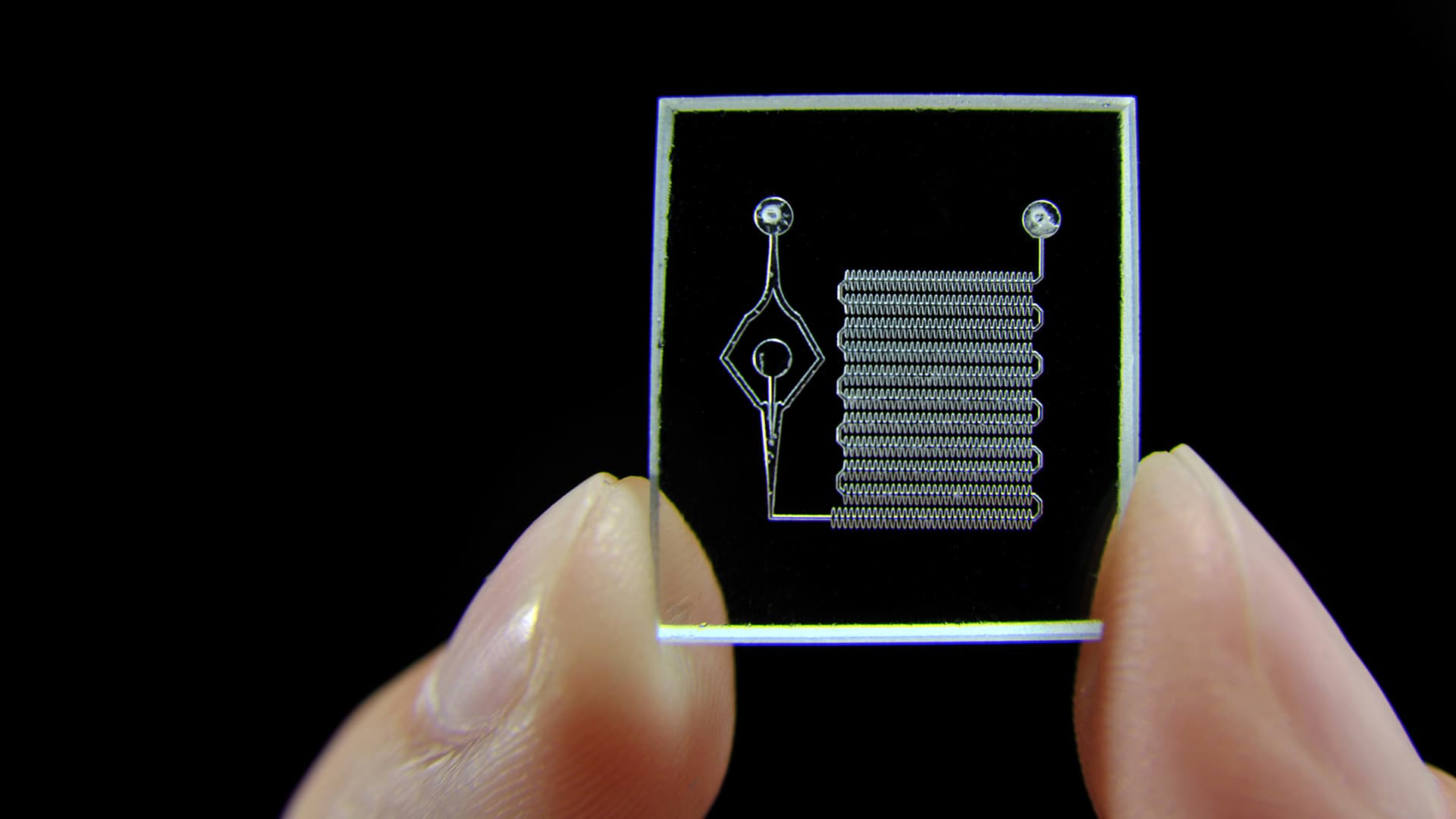

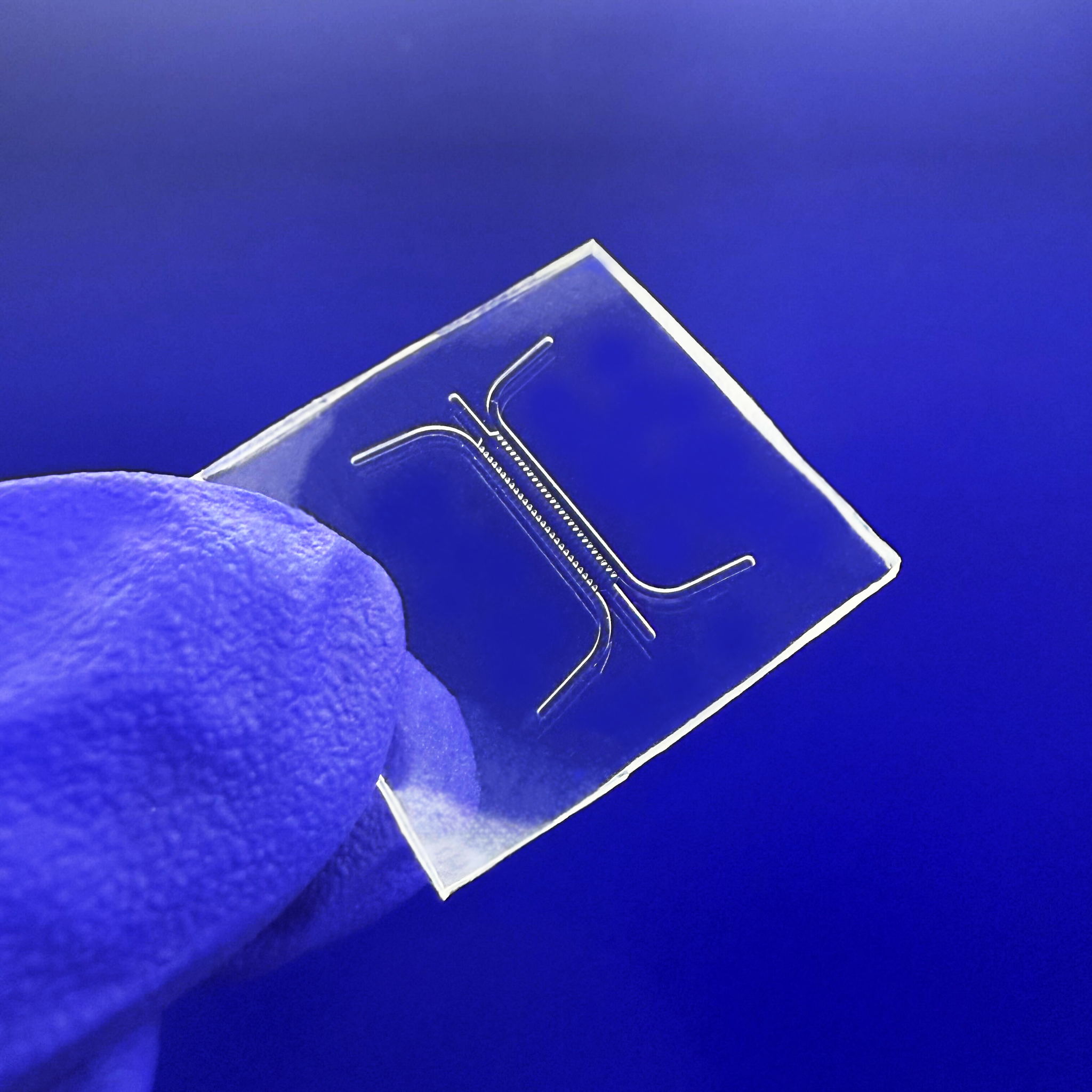

A microfluidic chip is a miniaturized device that contains networks of microchannels, valves, and chambers to manipulate fluids precisely.

Common Types of Microfluidic Devices:

Continuous-Flow Chips: For mixing, separation, and chemical reactions

Droplet-Based Chips: Create isolated compartments for single-cell or digital PCR applications

Paper-Based Microfluidics: Low-cost diagnostic tools, often disposable

Valved Microfluidic Chips: Enable automation using integrated microvalves

Design Considerations:

Channel Geometry: Affects fluid resistance and mixing

Material Selection: Must be chemically and biologically compatible

Sensor Integration: Allows real-time monitoring

Scalability: For transitioning from prototype to produc

Tip: Want to design your first microfluidic chip? Try FLUI’DEVICE our free online microfluidic design and simulation platform!

Microfluidic Applications in 2025

Lab-on-a-Chip (LoC):

LoC devices miniaturize complex lab workflows onto a single chip, commonly used for:

COVID-19 & infectious disease testing

PCR and genetic screening

Multi-analyte detection

Organ-on-a-Chip & Microphysiological Systems (MPS)

Organ-on-a-chip platforms replicate biological functions of human organs using living cells and microfluidic environments.

These systems are crucial for:

Drug toxicity testing

Disease modeling

Personalized medicine

They include:

Organoids (3D cellular models)

Micropatterned scaffolds

Dynamic flow environments

Drug Discovery and Development

Microfluidic systems accelerate pharmaceutical R&D by enabling:

High-throughput screening

Miniaturized reaction volumes

Single-cell pharmacology studies

Controlled drug release testing

Environmental and Food Safety

Portable microfluidic devices are used for:

Water quality testing (nitrates, lead, bacteria)

Soil and crop pathogen detection

Foodborne contamination diagnosis

This is especially impactful in resource-limited and on-site testing scenarios.

Microfluidic Device Fabrication: Materials and Methods

While PDMS remains a standard, fabrication methods have diversified:

| Material/Method | Benefits |

|---|---|

| Flexdym™ | Biocompatible, thermoplastic, cleanroom-free |

| 3D Printing | Rapid prototyping and custom geometries |

| Hot Embossing | Industrial-scale replication |

| Paper Substrates | Ultra-low-cost diagnostics |

Need help getting started? Our POC Kit and online video tutorials make it easy.

How to Get Started with Microfluidics (No Cleanroom Needed!)

- FLUI’DEVICE – Free platform to design and simulate your chip online

- POC Kit – Affordable microfluidic prototyping tools

- YouTube Tutorials – Hands-on demonstrations

- Microfluidic Blog – Expert articles and case studies

Explore our microfluidics blog section for design tips and case studies.

Challenges & Trends in Microfluidics

Despite the growing adoption, challenges remain:

Scaling from prototypes to mass production

Material limitations (chemical resistance, biocompatibility)

Integration with electronics, optics, and AI

Emerging Trends:

AI-driven microfluidics

Biodegradable and sustainable chip materials

Open-source design and cloud collaboration

Multi-layer and hybrid microfluidic systems

Learn More About Microfluidics

Don’t forget to check out our YouTube channel for demonstrations and tutorials.

Frequently Asked Questions (FAQs)

What is microfluidics used for?

Microfluidics enables precise fluid manipulation for use in diagnostics, drug development, environmental monitoring, and cell biology research.

What is a microfluidic chip?

It’s a device with micrometer-scale channels that control the movement of fluids. Applications include DNA analysis, cell culture, chemical synthesis, and more.

How does microfluidics work?

It operates based on laminar flow, diffusion, capillary forces, and sometimes electrokinetic effects. This enables high-precision control over fluid behavior.

Can I design a microfluidic chip without engineering experience?

Yes! Tools like FLUI’DEVICE allow anyone to design microfluidic devices online no CAD or cleanroom required.

What software can I use for microfluidic design?

FLUI’DEVICE (free and browser-based)

COMSOL Multiphysics (advanced simulations)

SolidWorks/AutoCAD (CAD design)

References

Whitesides, G. M. (2006). The origins and the future of microfluidics. Nature, 442(7101), 368–373. https://doi.org/10.1038/nature05058

Sia, S. K., & Whitesides, G. M. (2003). Microfluidic devices fabricated in poly(dimethylsiloxane) for biological studies. Electrophoresis, 24(21), 3563–3576. https://doi.org/10.1002/elps.200305584

Chin, C. D., Linder, V., & Sia, S. K. (2012). Commercialization of microfluidic point-of-care diagnostic devices. Lab on a Chip, 12(12), 2118–2134. https://doi.org/10.1039/C2LC21204H

Bhatia, S. N., & Ingber, D. E. (2014). Microfluidic organs-on-chips. Nature Biotechnology, 32, 760–772. https://doi.org/10.1038/nbt.2989

Low, L. A., Mummery, C., Berridge, B. R., Austin, C. P., & Tagle, D. A. (2021). Organs-on-chips: Into the next decade. Nature Reviews Drug Discovery, 20(5), 345–361. https://doi.org/10.1038/s41573-020-0079-3

Zhang, C., Xing, D. (2018). Miniaturized microfluidic devices for biomolecular analysis and medical diagnostics. Lab on a Chip, 18, 1156–1169.

Squires, T. M., & Quake, S. R. (2005). Microfluidics: Fluid physics at the nanoliter scale. Reviews of Modern Physics, 77(3), 977–1026.

Eden Materials

Paris 75012, France