SUBLYM

Device Replication and Assembly

Sublym

The Sublym100 is a great alternative to soft-lithography microfabrication, for easy and quick production of your microfluidic devices.

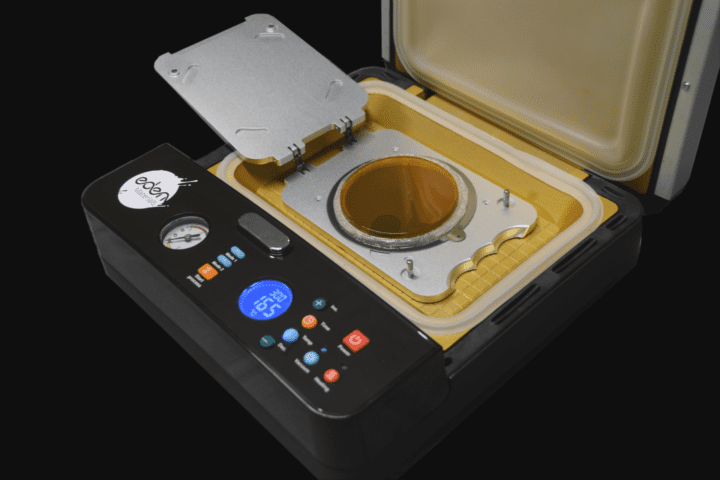

The SuBlym100 is a hot embossing machine, using heat and pressure to mold a variety of materials in a matter of minutes. More specifically, it has been optimized for Flexdym polymer molding in only 2 minutes, but can also be used to mold various other thermoplastics, including PMMA.

Do you require an alternative to soft-lithography microfabrication? Because the Sublym™ hot embossing machine is a great option for easy and quick production of microfluidic chips.

The Sublym™ is a hot embossing machine, using heat and pressure to mold a variety of materials in a matter of minutes, including Flexdym™, COC, PMMA and PS. Consequently, it serves as a great alternative to soft-lithography casting. More specifically, the Sublym100 has been optimized for Flexdym™ polymer molding in only 2 minutes, but it can also be used to mold various other thermoplastics, including PMMA.

Check out below additional advantages of the Sublym™:

- Easy-to-use, with no extensive training is needed to operate it. The Sublym™ is the perfect equipment for accelerating projects.

- An ultra-compact design, that’s not much bigger than a laptop. The Sublym™ is dramatically smaller than standard commercial hot embossing machines, weighing up to 500 kg.

- A user-friendly system, that is only powered by electricity. You can plug-and-play in the smallest of spaces.

- Dramatically cheaper than other microfabrication equipment. The Sublym™ makes microfluidics more accessible to everyone.

4 Easy steps to create Flexdym chips using the Sublym™:

- Cut a Flexdym™ sheet to the size of your device.

- Next, mold the sheet by placing the sheet, between your mold and the counter mold (included in the Sublym kit), inside the machine.

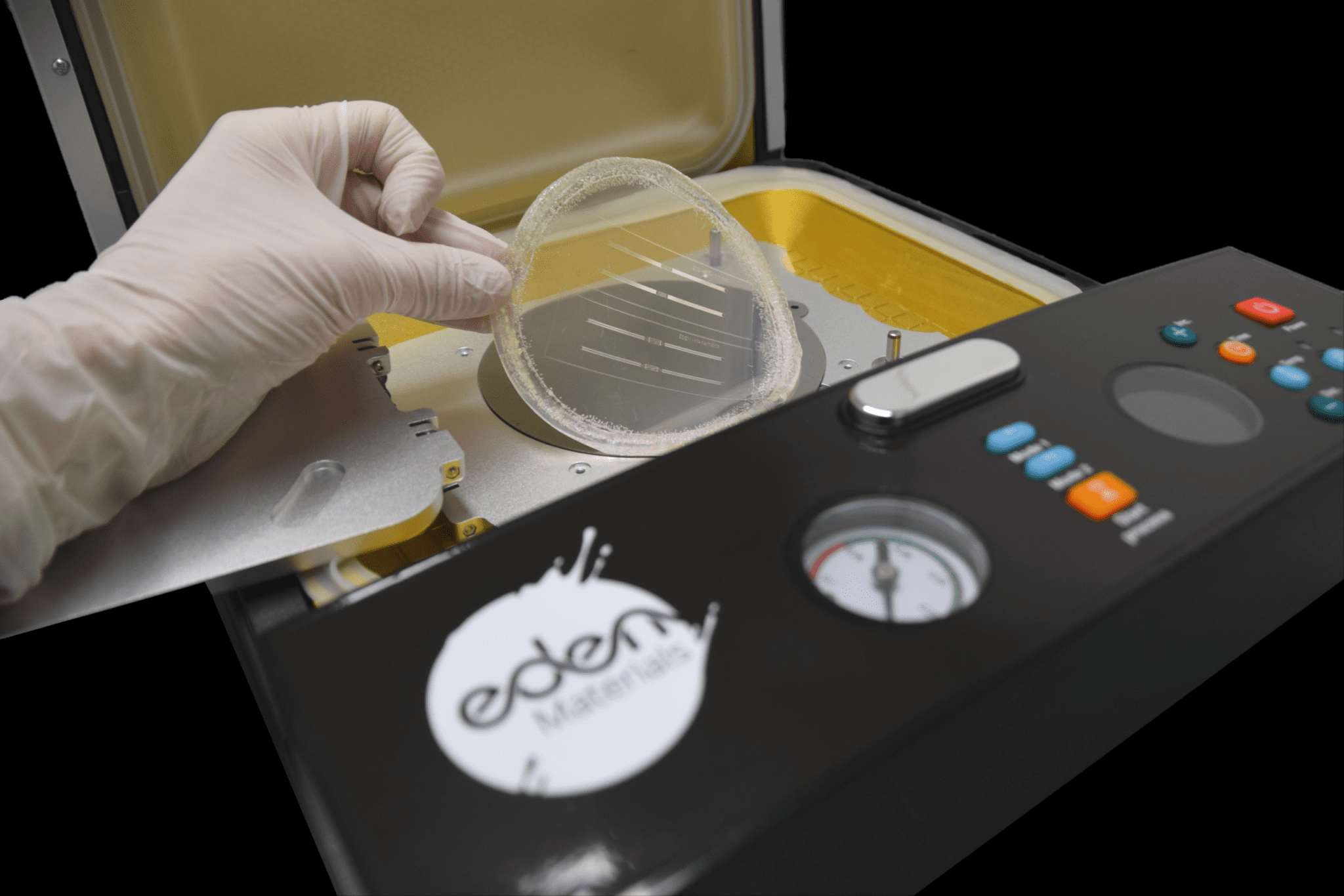

- Then, unmold the sheet and create inlet/outlet ports. Check out our metal punch pliers for this step.

- Finally, laminate sheet onto substrate. Flexdym™ can bond to various materials including, itself, glass, PDMS, PS, PC, COC, COP and PMMA.

A note to our Flex users: the Sublym also serves a great bonding aid for standardized Flexdym™ chip bonding.

This microfabrication countertop companion allows quick prototyping and production of microfluidic chips at a push of a button! What else could you need?

Want to find out more on what types of molds to use in hot embossing? Check out our Epoxym™ kit, solution for replicating molds.

And make sure to follow us on LinkedIn and Youtube to get all our current news.

| Dimension | 33 x 34 x 11 cm3 |

|---|---|

| Molding size | Up to 4" in diameter (Suitable for multiple microscope slide molding) |

| Max Mold Thickness | 1cm (Opt:1.5cm) |

| Temperature | 50°C – 180°C |

| Temperature Ramp | 180°C / 5min |

| Approximate Force | 1.2kN to 1.8kN |

| Power | 800W |

| Heat Resistant Gloves Size | Small, Medium, Large |