POINT-OF-CARE

Scale-up Kit

Point-of-Care Scale-Up Kit

Are you struggling with your microfluidics Point-of-Care (POC) device development and scale-up?

Eden Tech’s scale-up kit for point-of-care diagnostics is the solution you need to boost your microfluidic device fabrication, for a research project or product development. The Scale-Up Kit is designed for researchers facing challenges in their device fabrication and production related to… material properties, non-scalable material, complicated fabrication processes, or strict deadlines.

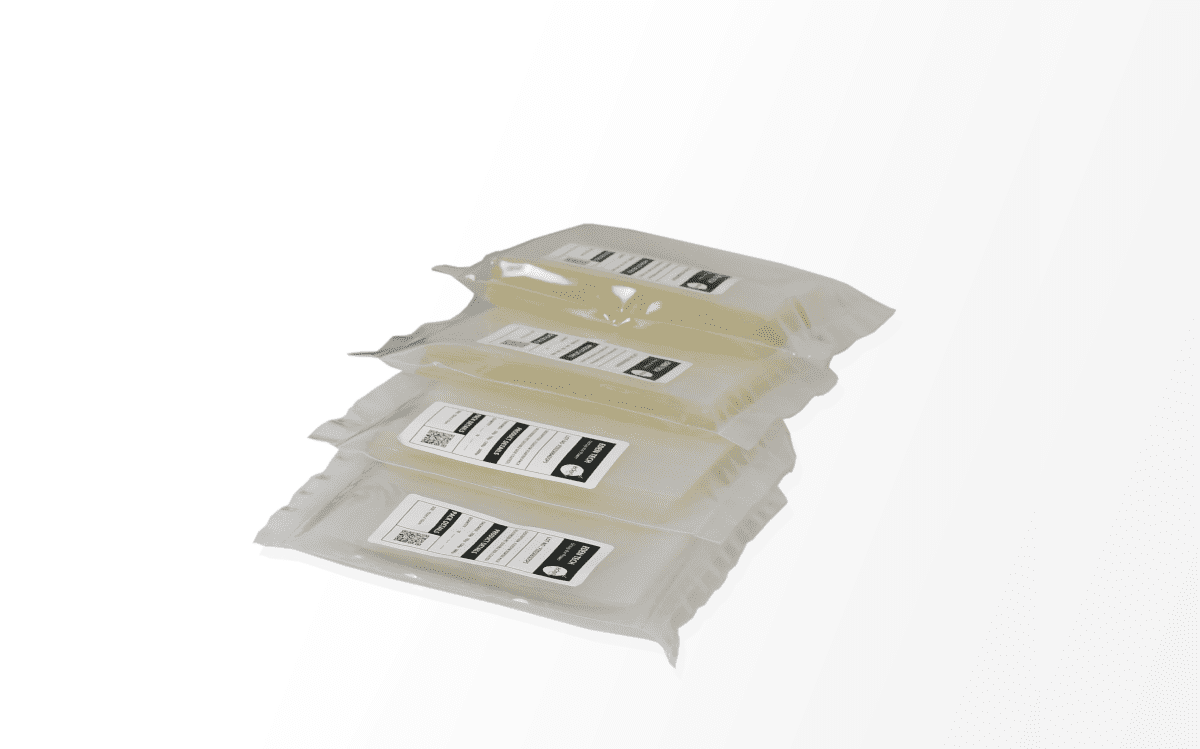

The Point-of-Care Scale-Up kit contains biocompatible polymer, Flexdym, is a thermoplastic elastomer that serves as a great alternative to PDMS, combining its most desired material properties with the efficiency of fabrication processes used for thermoplastics.

The Scale-Up Kit includes everything you need to get started with Flexdym for point-of-care device fabrication: the Sublym hot embossing machine, 4 Flexdym start packs, the Epoxym mold solution, 5 connector sets, and a port puncher. With this kit you will be able to scale-up your device production from small scale to medium scale production with our user-friendly and efficient protocols. Once you are ready to begin mass production, know that the Flexdym is compatible with both roll-to-roll embossing and injection molding methods.

Unlike most other materials commonly used in microfluidics, Flexdym is the first material specifically formulated and developed for microfluidic diagnostic applications. Originally developed by our CEO, Emmanuel Roy, Flexdym was created for a point-of-care diagnostics and incorporates key material properties for these applications including softness, elasticity, optical transparency, instant assembly, treatment-free bonding, and compatibility with manufacturing processes at all scales of production. Flexdym takes you from initial prototyping to commercialization.

To find out more and watch protocol videos, check out our youtube.

You can also follow us on Linkedin for regular updates or contact us directly!

| Optional | Epoxym Incl., Epoxym Not Incl. |

|---|---|

| Connector Type | Luer, Olive |

| Puncher Die cut | 0.5 mm, 1 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 3.5 mm, 4 mm, 5 mm |

| Heat Resistant Gloves Size | Small, Medium, Large |

The microfluidic Point-of-Care Scale-Up Kit is a complete solution for innovators struggling with their cartridge design & development. It requires a small investment and provides all of the components needed for mold replication, device replication, device assembly, device bonding & chip-to-world experimental setup. The Point-of-Care Scale-Up Kit includes: The Flexdym biocompatible and scalable polymer, the Sublym portable hot embossing machine, the Epoxym mold replication solution and inlet/outlet accessories. Request Product Kit Brochure