What Is a Microfluidic Chip? A Beginner’s Guide to Microfluidics

Microfluidic chips are tiny, powerful devices that allow scientists and engineers to manipulate fluids at the microliter or nanoliter scale. These “lab-on-a-chip” systems are revolutionizing science and engineering, offering faster, cheaper, and more precise methods in biomedical research, chemistry, diagnostics, and beyond.

Whether you’re curious about how microfluidic devices work or how to make one, this beginner-friendly guide will walk you through everything: from the basics to fabrication techniques and real-world applications.

What Is a Microfluidic Chip?

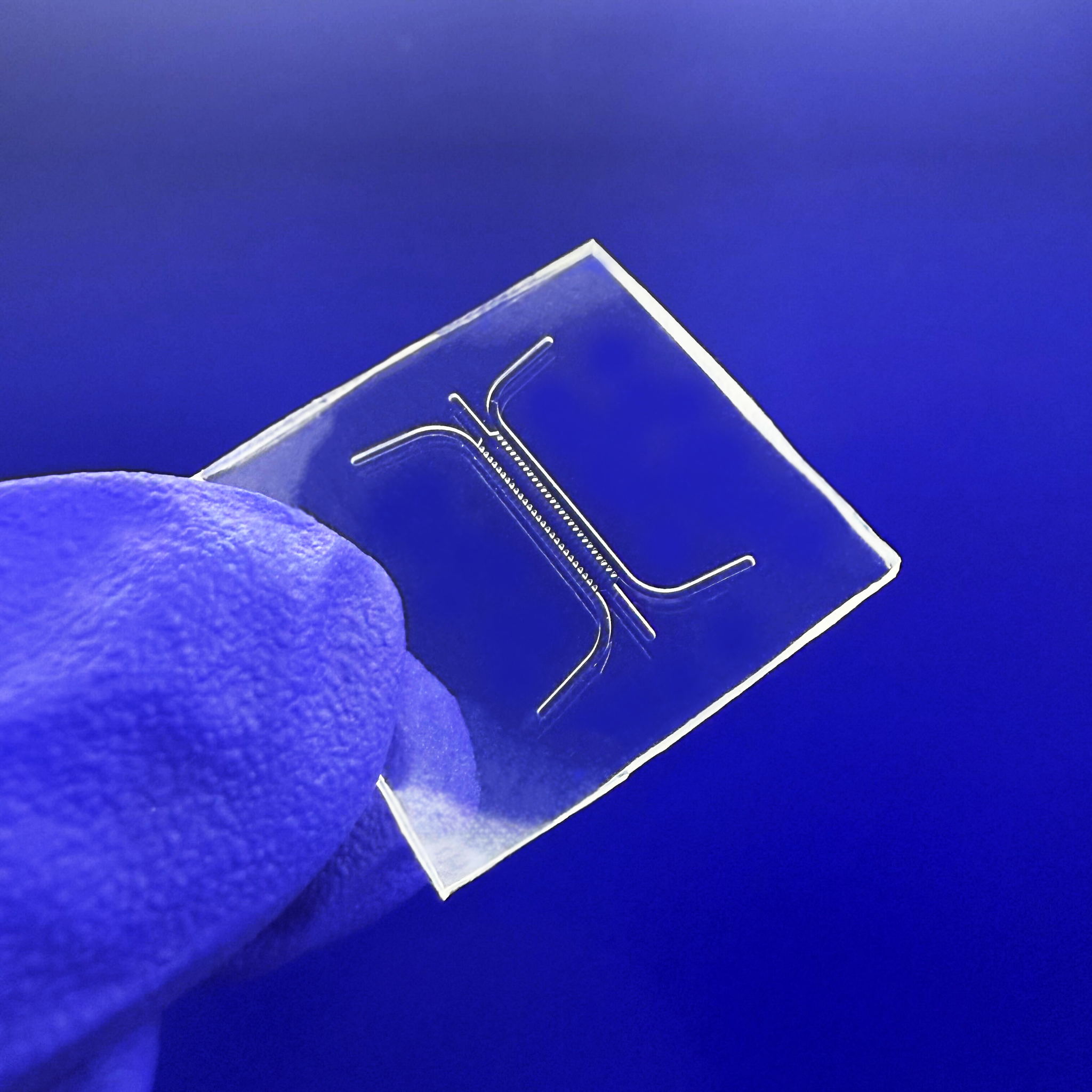

A microfluidic chip is a compact device made of tiny channels, usually between 10 and 500 micrometers wide, that control the flow of fluids. These chips can replicate entire lab processes, such as mixing, heating, separating, and detecting, all on a device smaller than a credit card.

Common materials for microfluidic chips include:

- PDMS

- Flexdym

- Glass

- Silicon

- Thermoplastics (like COC or PMMA)

Key feature: A microfluidic chip combines multiple laboratory operations into a single, portable platform ideal for diagnostics, biotech, and research labs.

How Do Microfluidic Chips Work?

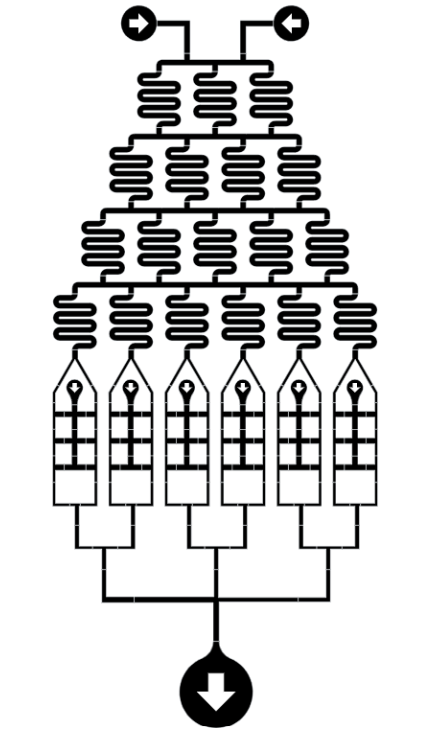

Fluids enter through tiny inlets, move through micro-scale channels, and exit via outlets. Pumps, pressure systems, or syringes guide fluid flow. At such small volumes, microfluidics enables:

Extremely low reagent use

Rapid heat and mass transfer

Fast, parallelized experiments

Portable, battery-operated diagnostics

Microfluidic Chip Fabrication: How Are They Made?

Fabrication techniques vary based on resolution, material, and production volume. Here are the most common:

Common Materials

Flexdym & PDMS: Easy to mold, optically transparent, and biocompatible.

Glass: Chemically resistant and suitable for high-pressure or optical applications.

Thermoplastics (e.g., COC, PMMA): Ideal for scalable production by injection molding or hot embossing.

Silicon: High-precision but expensive, often used in MEMS and sensors.

Microfabrication Techniques

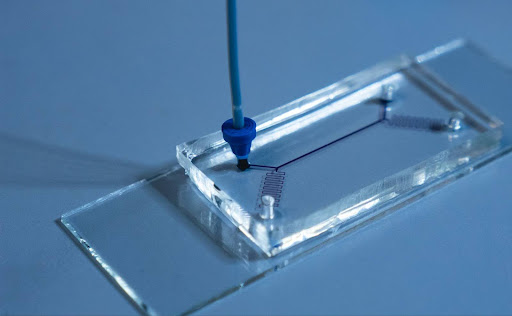

Soft Lithography (PDMS)

Standard in academia. Involves creating a mold with photolithography, casting PDMS, and bonding it to a substrate.Hot Embossing

Used for Flexdym and thermoplastics. Fast and scalable. Molds made of resin or metal.3D Printing

Offers rapid prototyping with growing resolution—perfect for multilayer or complex chips.

Microfluidic Chip Applications: What Are They Used For?

Microfluidic devices are used in dozens of industries:

| Field | Microfluidic Chip Use |

|---|---|

| Biomedical diagnostics | Point-of-care testing, blood analysis, PCR |

| Cell biology | Single-cell manipulation, live imaging, cell sorting |

| Drug discovery | High-throughput screening, organ-on-a-chip |

| Chemistry | Microreactors, crystallization, flow chemistry |

| Environmental monitoring | Water and air quality testing |

| Energy | Micro fuel cells, thermal management |

Did you know? The concept of microfluidic chips was inspired by microelectronics in the 1980s and is now integral to portable diagnostic kits.

Why Use a Microfluidic Chip?

Microfluidic chips are better than traditional lab tools because they are:

Faster – reactions take seconds instead of hours

Cheaper – use fewer reagents and samples

Smaller – can fit in a pocket-sized device

More accurate – precise control over fluid flow

Scalable – from prototype to production

Microfluidic Chip Design: Getting Started

Designing a chip starts with understanding your application: do you need mixing, droplet generation, cell culture, or gradient formation? Tools like FLUI’DEVICE, AutoCAD, or SolidWorks can be used to prototype your chip virtually.

Key design considerations:

Channel width and height (influence flow resistance and shear stress)

Connection interfaces (inlet/outlet size)

Material compatibility with your fluids and assays

Bonding technique and leak-proof sealing

Tip: Use modular platforms or microfluidic design software that allows simulation and export to STL/DXF formats to speed up the process.

Where to Buy or Make Microfluidic Chips

Depending on your resources and timeline, you can:

- Make Your Own: With user-friendly tools like FLUI’MOLD, Flexdym, and the Sublym hot embossing machine, you can quickly design and fabricate chips without a clean room. Ideal for fast prototyping and flexibility.

- Use a Clean Room: Good for traditional PDMS soft lithography, but time-consuming and expensive.

- Work with a Manufacturer: Companies like Aline Inc or Oscar Zabaco offer custom design and manufacturing services, perfect for scaling up or getting production-ready chips.

- Buy Standard Chips: Suppliers like Darwin Microfluidics or Dolomite offer off-the-shelf microfluidic chips for common applications, ready to use with no setup needed.

Conclusion : Why Microfluidics Matters

Microfluidic chips are at the heart of innovation in biology, chemistry, and diagnostics. As tools become easier to use and fabrication more accessible, microfluidics is no longer just for experts it’s for students, startups, and creators too.

Whether you’re building a prototype, learning about lab-on-a-chip systems, or scaling a medical device, now is the perfect time to dive into microfluidic technology.

References

Whitesides, G. M. (2006). The origins and the future of microfluidics, Nature. https://doi.org/10.1038/nature05058

Duffy, D. C. et al. (1998). Rapid Prototyping of Microfluidic Systems in Poly(dimethylsiloxane). Analytical Chemistry. 10.1021/ac980656z

Sia, S. K. & Kricka, L. J. (2008). Microfluidics and point-of-care testing. Lab on a Chip. https://doi.org/10.1039/b711659g

Zhu, H. et al. (2015). Paper-based microfluidic device for rapid detection of Ebola virus. Lab on a Chip. https://doi.org/10.1039/c4lc01279g