Two-Photon Polymerization 3D Printing for Microfluidics - Application Note

Introduction

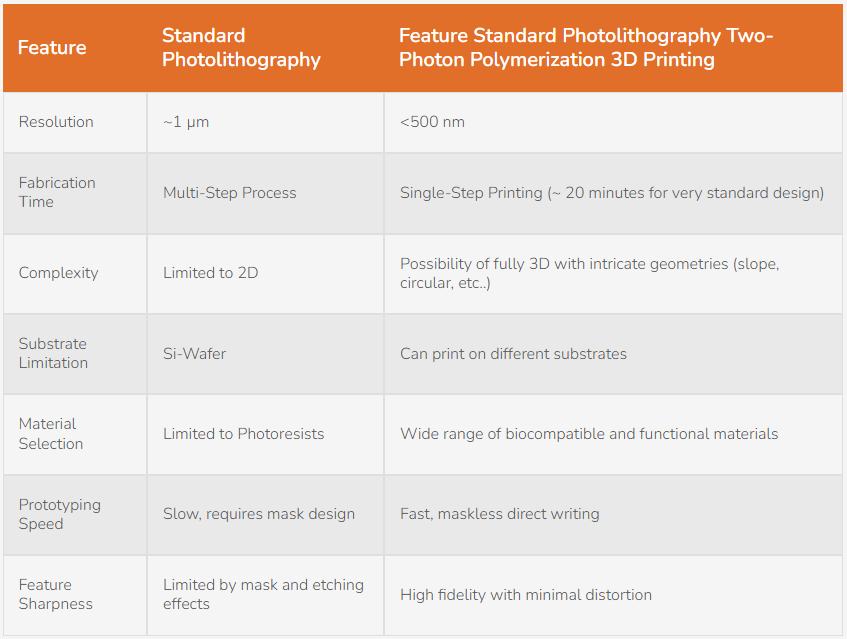

The field of microfluidics is undergoing a significant transformation thanks to advancements in 3D printing, which enable the creation of complex microfluidic systems with greater flexibility. Microfluidic device fabrication has traditionally relied on standard photolithography techniques, which provide high resolution but are often limited in geometric complexity. Two-photon polymerization (2PP) 3D printing has emerged as a powerful alternative, enabling rapid prototyping of elaborate microfluidic structures with sub-micron precision. This application note highlights the advantages of 2PP 3D printing for microfluidics.

Principle of Two-Photon Polymerization

Two-Photon Polymerization 3D Printing for Microfluidics is an advanced 3D printing technique that utilizes a femtosecond laser to induce localized polymerization through two-photon absorption. This nonlinear optical process enables ultra-high resolution fabrication beyond the diffraction limit of conventional lithography, allowing for the direct writing of complex 3D structures in photopolymerizable resins.

Applications of Two-Photon Polymerization 3D Printing in Microfluidics

In microfluidics, 2PP offers several applications, including:

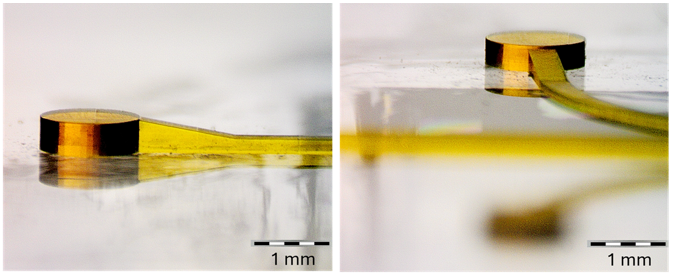

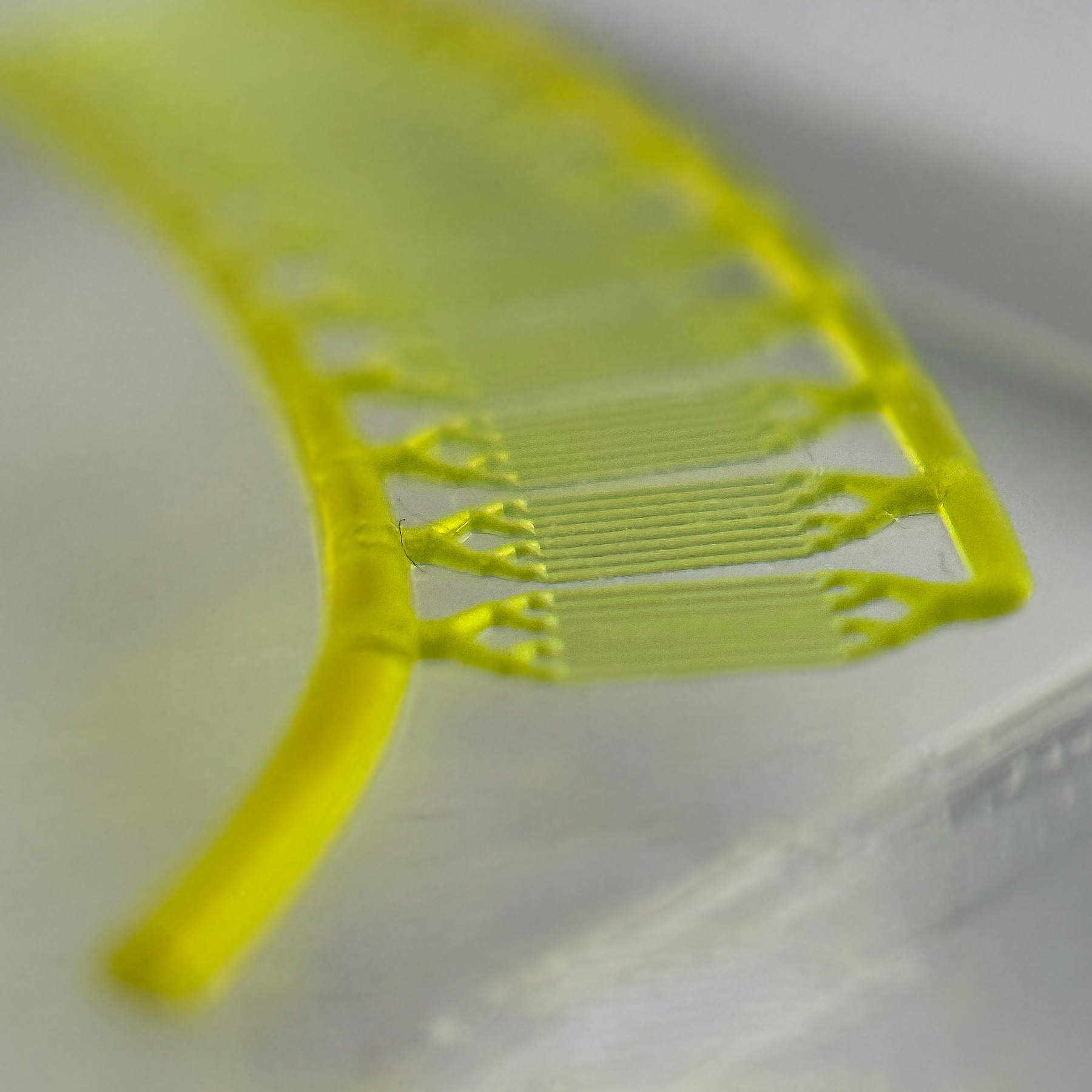

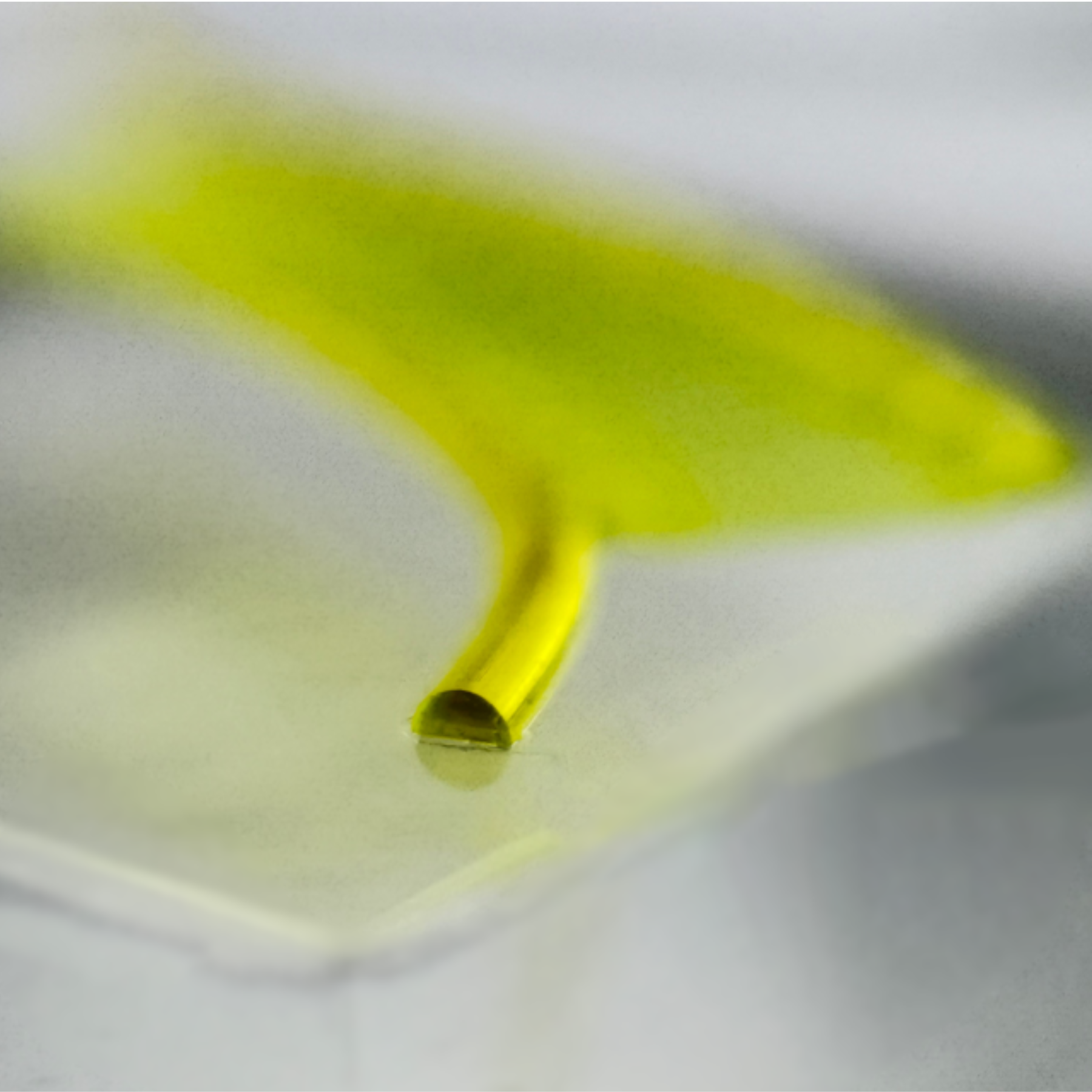

Fabrication of Microchannels and Complex Geometries

This technology permits the creation of intricate and complex microfluidics structures, such as round or slope (figure1), with smooth and high resolution features, that would be challenging to fabricate using conventional lithography.

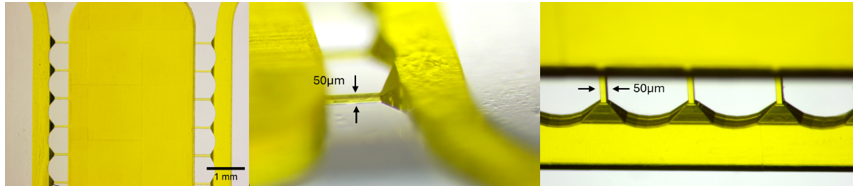

Lab-on-a-Chip Devices

2PP allows high-resolution fabrication of lab-on-a-chip platforms for medical diagnostics, chemical analysis, and biological studies. It make possible the integration of functional components such as mixers, separators, and biosensors with different heights in a single production step (figure2). Unlike conventional fabrication methods, 2PP allows for quick design iterations, making it ideal for prototyping personalized LoC devices. Moreover, there is no need any longer of multiple mask and multi-step process.

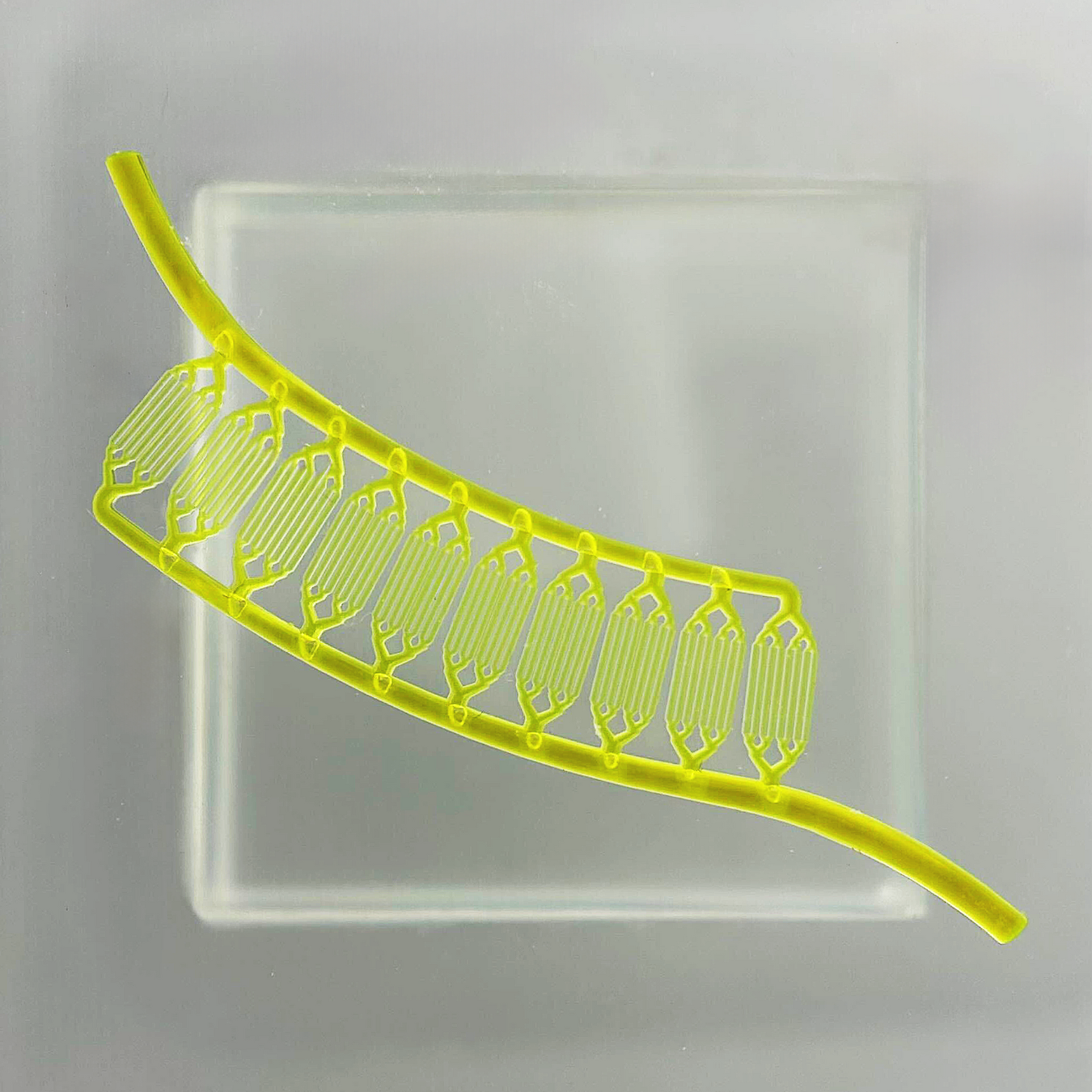

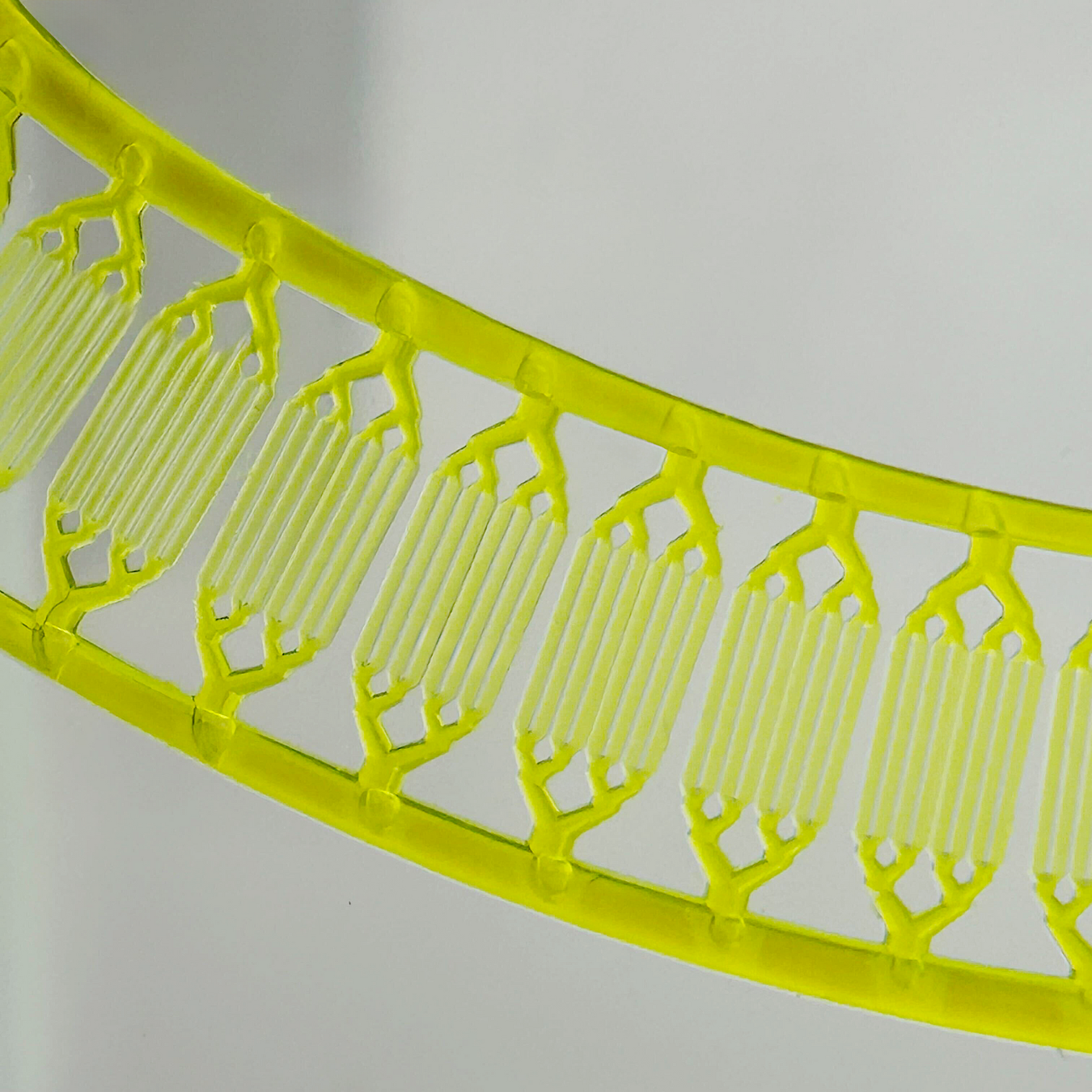

Organs-on-a-Chip

Customizable structures for cell culture, drug screening, and organ-on-chip models. 2PP can create biomimetic microenvironments. It is particularly useful for developing microfluidic chips for studying cell behavior under controlled conditions. For example, one of the biggest challenges in tissue engineering is creating artificial blood vessels to sustain cells. 2PP enables the fabrication of microvascular networks that simulate real capillary structures (figure3). This improves oxygen and nutrient diffusion, supporting long-term cell viability.

Figure3: microvascular networks that simulate capillary structures

Microneedles and Drug Delivery

The technique enables the fabrication of micro-needles with complex internal structures for controlled drug release. Such systems enhance targeted delivery while minimizing patient distress.

Advantages of Two-Photon Polymerization in Microfluidics

- High Resolution and Precision: Achieves sub-micron feature sizes, enabling precise control over microchannel dimensions and complex microstructures.

- True 3D Fabrication: Overcomes the 2D limitations of photolithography, allowing for the creation of intricate, multi-level channels.

- Rapid Prototyping: Eliminates the need for photomasks and/or etching, reducing iterative design improvements.

- Scalability and Customization: Enables the fabrication of unique, application-specific designs in biomedical applications, lab-on-a-chip devices, and organ-on-a-chip platforms.

- Minimal Waste and Environmental Impact: Produces structures with minimal material waste compared to traditional lithographic processes.

Comparison with Standard Photolithography:

Conclusion

Two-photon polymerization 3D printing represents a transformative approach for microfluidic fabrication, overcoming the limitations of traditional photolithography. Its ability to create high-resolution, fully 3D, and customizable structures positions it as a crucial technology for the next generation of microfluidic applications. As 2PP continues to evolve, its adoption in research and industrial settings is expected to expand, driving innovation in biomedical engineering, diagnostics, and beyond.