Reversible Bonding in Microfluidics: A PDMS Alternative

In the evolving field of microfluidics, the demand for reusable, biocompatible, and easy-to-access devices is growing rapidly. Traditional materials such as polydimethylsiloxane (PDMS), while widely used, show major limitations. Especially when it comes to reversible bonding and small molecule adsorption. A recent study by Moreau et al. introduces a compelling solution: Flexdym, a styrenic block copolymer (SBC), as a reversible bonding microfluidics material and a sustainable alternative to PDMS.

Why Reversible Bonding Matters

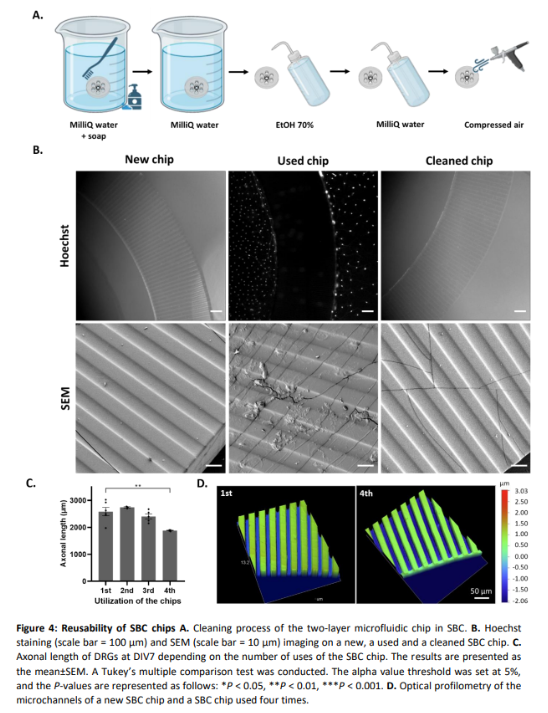

Microfluidic systems are increasingly used in biological and neurophysiological research, particularly for in vitro modeling. A key limitation of many traditional devices is their irreversible bonding. Making it difficult to access cells for downstream analysis or to reuse the chip for multiple experiments. The ability to open, clean, and reassemble a chip expands the possibilities for imaging, molecular biology assays, and long-term cost efficiency.

As highlighted in the study:

The reversible bonding properties of the SBC permit the reuse of the chip with a quick and easy cleaning protocol. It provides direct access to the cells, opening the way for imaging and molecular biology analysis.

[Moreau et al., 2024. https://doi.org/10.1101/2024.12.10.627139]

The PDMS Alternative Microfluidics Has Been Waiting For

Flexdym overcomes multiple issues associated with PDMS:

- Reversible Bonding: Unlike PDMS, which often requires plasma treatment or adhesives for bonding, Flexdym allows dry reversible bonding, that can be maintained through clamping. Making the device both reusable and modular.

- No Leachables: PDMS is known to leach uncrosslinked oligomers, which may interfere with sensitive cell cultures and assays. Flexdym, being a soft thermoplastic elastomer, does not exhibit this behavior.

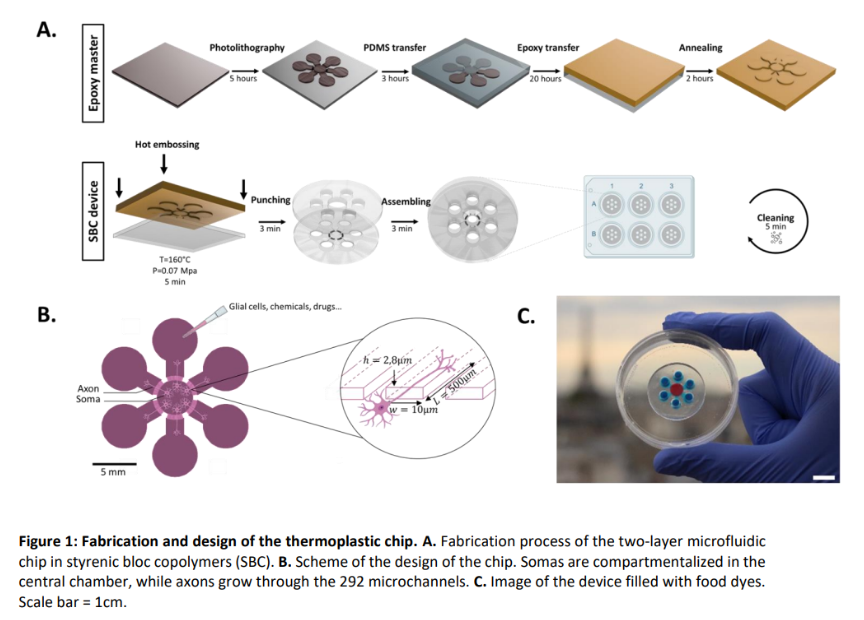

- Easy to Prototype: Flexdym can be hot embossed or molded without requiring a cleanroom, offering rapid prototyping capabilities, with standard benchtop tools.

- Sustainability: The ability to reuse Flexdym-based devices contributes to reduced lab waste and not to mention, the cost. A key consideration for scaling microfluidic research and applications.

The researchers emphasize this shift:

The comparison of the resources required to produce PDMS and SBC chips highlights the importance of moving to reusable devices.

[Moreau et al., 2024. https://doi.org/10.1101/2024.12.10.627139]

Application: Compartmentalized DRG Coculture on Flexdym Chips

In their study, Moreau et al. successfully cultured dorsal root ganglia (DRG) explants in a compartmentalized microfluidic chip, made entirely of Flexdym. Not only did this setup replicate known in vivo behaviors, but it also allowed the chip to be disassembled post-experiment. Enabling direct cell recovery and chip reuse, something not feasible with PDMS-based devices.

The study positions Flexdym as a viable material for compartmentalized, reusable, and biologically relevant microfluidic applications:

These detachable, easy-to-manufacture and sustainable all-thermoplastic platforms provide an alternative way of prototyping compartmentalized devices for in vitro PNS modeling.

[Moreau et al., 2024. https://doi.org/10.1101/2024.12.10.627139]

Final Thoughts

As microfluidics continues to support innovation in life sciences, researchers need more from their materials than biocompatibility alone. They need flexibility, reusability, and accessibility, properties that Flexdym delivers through its reversible bonding microfluidics capabilities.

If you’re developing microfluidic systems for neurobiology, drug screening, or organ-on-chip applications, it’s time to explore alternatives to PDMS. Flexdym offers a cleaner, smarter path forward, one that aligns with both scientific and sustainability goals.