How to Master Organ-on-Chip Design: Tools, Methods & Materials

Introduction to Organ-On-Chip

Organ-on-Chip (OoC) systems are transforming biomedical research by enabling more physiologically relevant models than traditional 2D cell cultures and animal testing. These microengineered systems integrate microfluidics, tissue engineering, and cell biology to simulate human organ functions in vitro.

As the field advances, robust and scalable organ-on-chip design methodologies become essential. This article explores the core design principles, key materials, and cutting-edge digital tools, such as FLUI’DEVICE, that streamline the design and prototyping of OoC platforms.

What is an Organ-on-Chip?

An Organ-on-Chip is a microfluidic device that replicates the architecture and dynamic microenvironment of human organs. By integrating living cells, perfused microchannels, membranes, and mechanical forces, these chips mimic key aspects of tissue function and physiology.

They are widely used in:

Drug development and screening

Toxicology testing

Disease modeling

Personalized medicine

Unlike static cultures, OoCs introduce fluid shear stress, cyclic strain, and compartmentalized co-culture, resulting in significantly higher biological relevance.

Core Principles of Organ-on-Chip Design

Microfluidic Architecture and Flow Control

The microfluidic layout is fundamental in organ-on-chip design. It governs how fluids, nutrients, and signaling molecules are delivered to cells and tissues.

Key design considerations:

Channel dimensions: Affect laminar flow, wall shear stress, and nutrient gradients

Flow regimes: Different organs require different shear conditions (e.g., gut vs. endothelium)

Parallel vs. serial flow: Essential for multi-organ models or “body-on-chip” setups

💡 Tip: Use CFD (computational fluid dynamics) simulations to validate and optimize flow profiles before fabrication.

Material Selection and Cell Compatibility

Material choice directly impacts the success of an organ-on-chip device. While PDMS is widely used, it absorbs hydrophobic small molecules, problematic for drug screening.

Alternative materials include:

COP/COC (Cyclic Olefin Polymers/Copolymers) – Ideal for mass production

PMMA – Transparent and easy to prototype, but with limited gas permeability.

Flexdym™: A soft, transparent elastomer that combines the ease of PDMS with improved chemical compatibility and lower small molecule adsorption, especially useful for barrier models and organ co-cultures

Each material affects:

Cell adhesion and viability

Optical transparency for imaging

Device bonding methods

🧪 If you’re testing new materials in early-stage development, it’s advisable to validate surface treatments, protein adsorption, and cell behavior.

Cell Culture Configurations and Barrier Functions

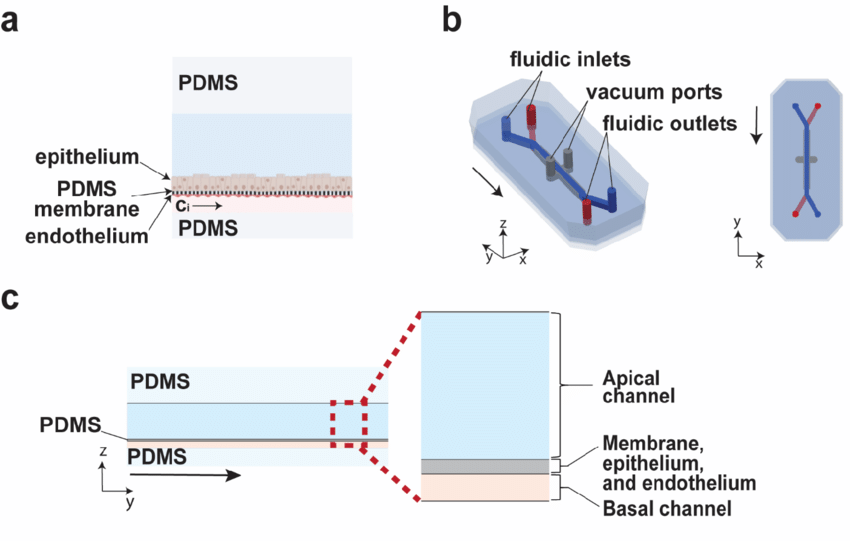

Most OoC devices are built around dual-channel structures separated by a porous membrane. This enables the co-culture of cell types at physiological interfaces, such as:

Lung (alveolar-capillary barrier)

Gut (intestinal wall)

Brain (blood-brain barrier)

Advanced OoC designs may also incorporate:

3D scaffolds or organoids

Dynamic mechanical forces (e.g., breathing, peristalsis

How to Design an Organ-on-Chip with FLUI'DEVICE

FLUI’DEVICE is a web-based CAD and simulation tool developed specifically for microfluidic design. It allows researchers, engineers, and students to create microfluidic devices, such as Organ-on-Chip platforms, quickly and intuitively, even without prior CAD experience.

Key Features for OoC Design

Modular design blocks: Easily assemble dual channels, mixers, valves, and junctions

Ready-to-use templates: Includes organ-specific layouts based on literature

Flow simulation: Test flow behavior, validate shear conditions

Export options: Generate STL, DXF, or SVG files for fabrication (soft lithography, 3D printing, or CNC)

Cloud-based access: Share designs and collaborate in real-time

📌 You can start with a free trial of FLUI’DEVICE to explore basic OoC layouts, or upgrade for full access to advanced modules and export tools.

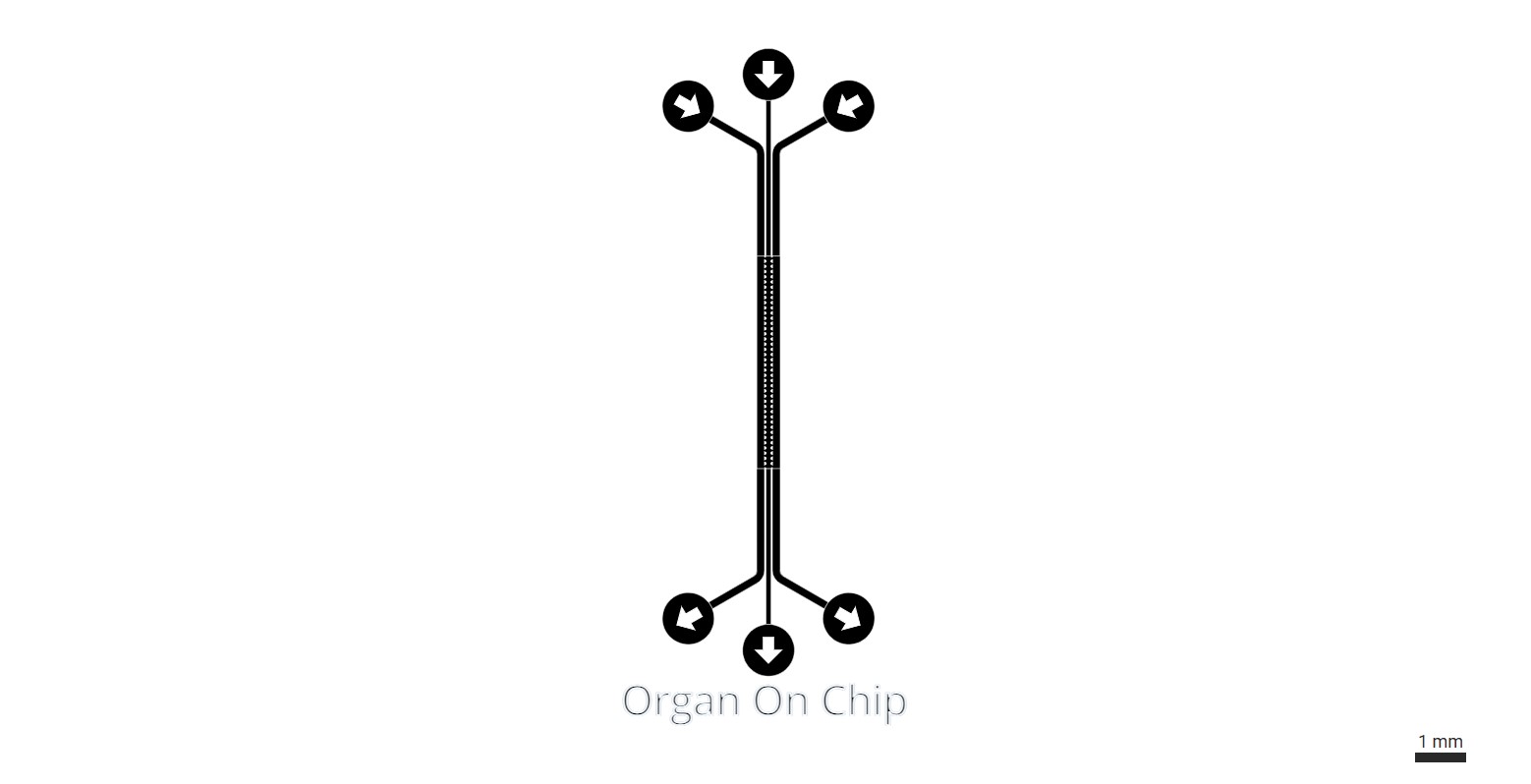

Organ-On-Chip Design

This Angiogenesis-On-Chip device is available on FLUI’DEVICE to assess angiongenic sprouting and functional vessel formation.

📌 You can try for free FLUI’DEVICE to experiment with simple Organ-on-Chip layouts, or upgrade to access advanced modules and exports.

Integrating Biology into Organ-on-Chip Design

Co-Culture and Barrier Models

OoC designs must support:

Multiple cell types with different media requirements

Membranes or gels to facilitate nutrient diffusion and paracrine signaling

Mechanical stimulation, such as peristalsis (gut) or cyclic strain (lung)

These require careful control of microchannel geometry, compartmentalization, and sometimes actuation systems (e.g., vacuum channels).

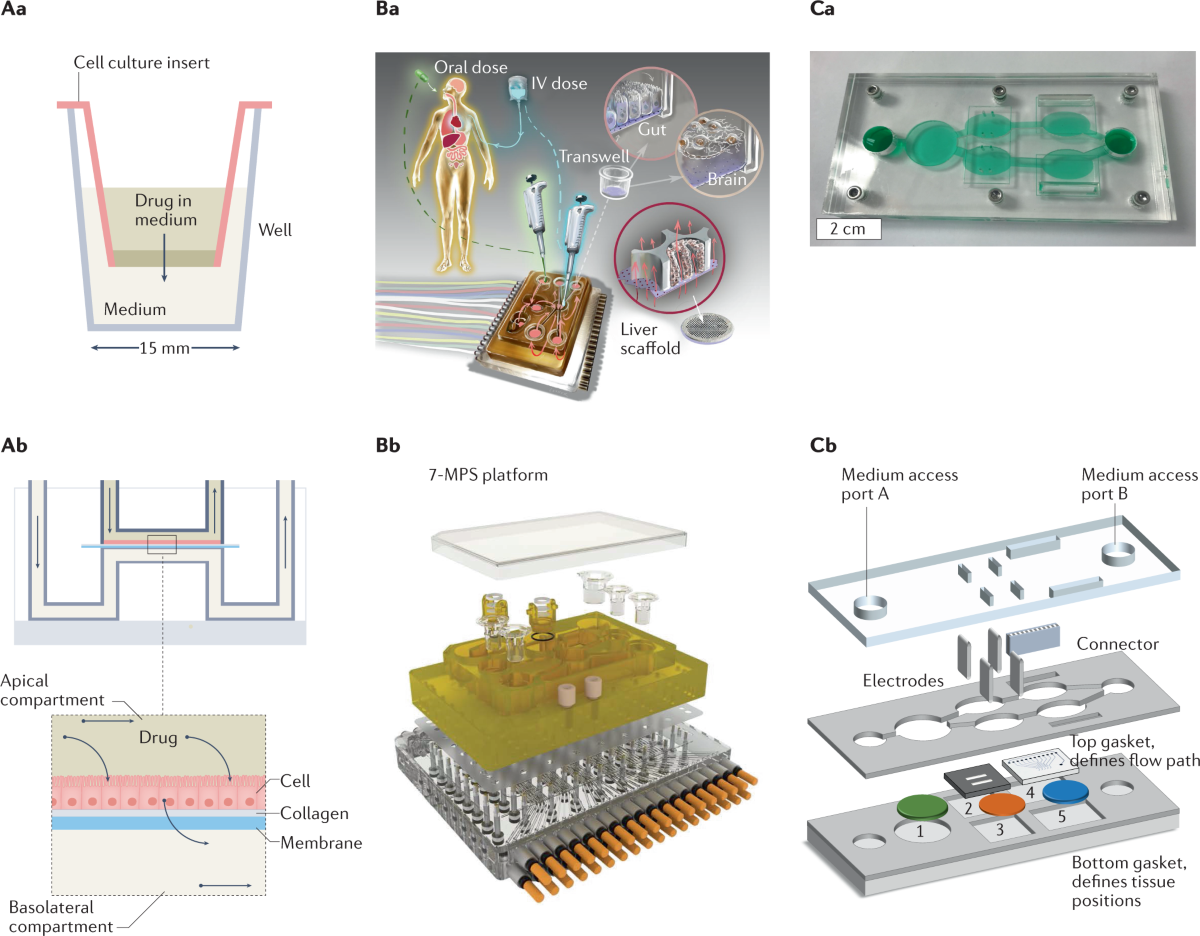

Real-Time Monitoring

Modern OoC platforms often integrate:

TEER electrodes to measure barrier integrity

Optical windows for live-cell imaging

Embedded sensors for oxygen, pH, or glucose

These features increase data quality and improve real-time analysis during experiments.

Organ-on-Chip Design Challenges

Despite their promise, OoC systems face several design and implementation challenges:

| Challenge | Why it matters |

|---|---|

| Material absorption | Affects drug concentration measurements |

| Reproducibility | Limits comparison across labs/devices |

| Fluidic complexity | Multi-organ systems can be unstable |

| Cell sourcing | Primary cells often vary between donors |

Successful OoC development requires balancing biological realism, device manufacturability, and experimental reproducibility.

Conclusion: Smarter Organ-on-Chip Design Starts with the Right Tools

Designing organ-on-chip systems is a multidisciplinary task involving microfluidics, cell biology, materials science, and data acquisition. Tools like FLUI’DEVICE empower researchers to create, simulate, and prototype microfluidic OoC systems in a streamlined way, accelerating the journey from concept to functional device.

As Organ-on-Chip technology moves toward clinical and industrial adoption, the convergence of design automation, accessible CAD tools, and robust material selection will play a key role in scaling this transformative technology.

Want to Start Designing Your Own Organ-on-Chip?

Try FLUI’DEVICE for free today and build your first microfluidic Organ-on-Chip prototype with just a few clicks no CAD skills required.

Visit FLUI’DEVICE to explore our tools, templates, and simulation features.

Q&A Organ-On-Chip Design

What are the most common organ models used in Organ-on-Chip systems?

The most widely developed models include:

Lung-on-Chip – Simulates alveolar-capillary interface with breathing motion

Gut-on-Chip – Reproduces peristaltic flow and intestinal barrier

Liver-on-Chip – Supports hepatocyte metabolism and drug clearance

Brain/Blood-Brain Barrier (BBB)-on-Chip – Models selective molecular transport

Kidney-on-Chip – Mimics glomerular filtration and proximal tubule functions

Multi-organ or body-on-chip platforms are also emerging to model systemic responses.

How do I design the membrane or barrier between two channels?

Barriers are typically designed as porous membranes that separate the apical and basal sides of the chip, allowing:

Nutrient diffusion

Paracrine signaling

Immune or drug transport

Design tips:

Use microporous PET, PDMS, or hydrogel membranes

Incorporate pores sized 0.4–8 μm, depending on application

Ensure good bonding between membrane and chip layers

How do you introduce cells and culture media in an OoC device?

Cells are typically seeded into channels or chambers using pipettes or automated systems. Media flow is maintained using:

Syringe pumps

Peristaltic pumps

Gravity-driven systems

On-chip pressure-driven flow systems

Design considerations:

Include inlets/outlets for seeding and perfusion

Design channels to avoid bubble formation and ensure uniform cell distribution

Use flow simulation tools to set appropriate shear stress levels for each tissue type

What kinds of sensors or readouts can be integrated into Organ-on-Chip designs?

OoC devices often incorporate:

TEER electrodes – for real-time barrier integrity measurements

Optical access – for fluorescence or live-cell imaging

Integrated sensors – for oxygen, pH, glucose, or metabolite levels

Sampling ports – for off-chip ELISA, qPCR, or metabolomics

Smart design enables both non-invasive monitoring and longitudinal analysis.

How do I prototype my Organ-on-Chip design after creating it in software?

Once designed in FLUI’DEVICE:

Export your design as an STL (3D printing), DXF (CNC), or SVG (photolithography)

- Produce your mold or order it with FLUI’MOLD

Choose your fabrication method:

Soft lithography (for PDMS prototypes)

3D printing (resins, elastomers, or mold masters)

CNC milling (especially for rigid polymers like PMMA or COC)

Assemble and bond layers, membrane, channels, inlets, with oxygen plasma, thermal bonding, or adhesives

Sterilize and seed with cells

You can iterate designs faster using digital tools before committing to costly physical prototyping.