Microfluidic Mixing: How to Design Efficient Micromixers for Lab-on-a-Chip Devices

What is Microfluidic Mixing?

Microfluidic mixing is fundamental to high-performance lab-on-a-chip systems. From PCR preparation to drug delivery and diagnostics, fast and reliable mixing at the microscale determines success. However, due to the dominance of laminar flow in microfluidic channels, achieving efficient mixing presents a major challenge.

This comprehensive guide explores the core mechanisms, compares passive vs active strategies, and offers step-by-step guidance to help engineers and researchers design high-efficiency micromixers. If you’re developing a microfluidic device, mastering microfluidic mixing will elevate your results, improve reproducibility, and save valuable time.

Why Is Microfluidic Mixing So Challenging?

In microscale systems, the Reynolds number is usually less than 1. This means fluid flow is laminar with virtually no turbulence. As a result, diffusion becomes the main mixing mechanism, which is inherently slow, especially in narrow, straight channels.

Poor microfluidic mixing can lead to:

Delayed or incomplete reactions in chemical and biological assays

Inaccurate reagent concentrations

Prolonged sample preparation

Reduced performance in single-cell and PCR workflows

To overcome these limitations, selecting the right micromixer design is essen

Types of Microfluidic Mixing Techniques

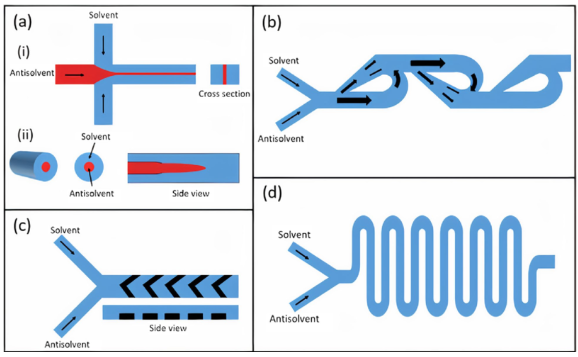

Passive Micromixing

Passive micromixers rely on channel geometry and flow manipulation to enhance mixing without external energy sources. By inducing chaotic advection, stretching, folding, or splitting flows, passive designs improve mixing via enhanced diffusion.

Common passive micromixer designs:

- T-shaped or Y-shaped junctions

- Herringbone structures (e.g., Staggered Herringbone Mixer, SHM)

- Serpentine and spiral channels

- Split-and-recombine (SAR) mixers

These designs are available and easy to simulate using tools like FLUI’DEVICE.

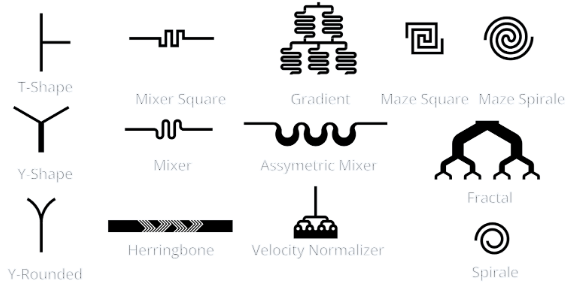

Type of passive micromixers you can find on FLUI’DEVICE

Advantages:

No need for external energy or components

Easy and cost-effective to fabricate

Well suited for point-of-care diagnostics and disposable chip

Limitations:

Mixing depends heavily on flow rate and channel length

Less tunable or controllable during operation

Active Micromixing:

Active micromixers use external energy sources to force mixing, often achieving faster and more uniform results.

Common Active Mixing Techniques:

Electrokinetic mixing (e.g., AC electroosmosis)

Acoustic mixing (surface acoustic waves)

Magnetic bead stirring

Localized thermal gradients

Advantages:

Faster and more uniform mixing

Greater control over mixing dynamics

Limitations:

- More complex to design and fabricate

- Require external power or control components

Microfluidic Mixing Design: Step-by-Step Guide

Whether you’re building a passive or active micromixer, the following design considerations are essential for success:

1. Understand Your Flow Regime

Estimate the Reynolds number in your system:

Re < 10: Diffusion dominates. Use long serpentine channels or SHM patterns.

Re > 10: Consider flow-focusing or vortex-inducing geometries.

.

2. Match Mixing Strategy to the Application

Passive Mixing: Ideal for diagnostics, low-cost testing kits, or simple reagent mixing.

Active Mixing: Best for drug delivery systems, synthetic biology, or complex chemical workflows.

3. Use Simulation Tools Before Fabrication

Simulating your mixer saves time and avoids trial-and-error. Tools like FLUI’DEVICE help you:

Design geometries visually

Simulate mixing performance

Predict pressure drops and flow paths

Real-World Applications of Microfluidic Mixing

Micromixers power a wide range of applications in microfluidics and lab-on-a-chip systems:

| Application | Role of Mixing |

|---|---|

| PCR and DNA amplification | Mix primers and samples uniformly |

| Drug screening | Combine reagents and cell suspensions |

| Chemical synthesis | Control reaction rates and product yield |

| Single-cell analysis | Precise lysis or reagent delivery |

| Isothermal amplification | Improve speed and reliability of diagnostics |

Summary: Key Takeaways for Microfluidic Mixing Design

To build efficient micromixers:

Choose the right mixing strategy based on your flow regime and application

Design geometries that encourage chaotic advection or stretch/diffuse interfaces

Simulate designs with tools like FLUI’DEVICE to reduce prototyping time

As microfluidics advances biotech, diagnostics, and chemistry, mastering microfluidic mixing will be a major advantage for your device performance and time-to-market.

Start Designing Your Micromixer Now

Try FLUI’DEVICE — a powerful browser-based tool to prototype, simulate, and export microfluidic mixer designs in minutes. Whether you’re developing passive or active mixers, FLUI’DEVICE offers:

Drag-and-drop interface

Instant simulations

Export options in SVG, STL, or DXF

Microfluidic Mixing FAQ

What is microfluidic mixing? Microfluidic mixing refers to the blending of fluids at the microscale using specialized micromixer designs. It’s essential for uniform reactions in lab-on-a-chip devices.

What is the difference between passive and active microfluidic mixing? Passive mixing uses the channel design to manipulate flow, while active mixing involves external forces like electric fields or acoustic waves to stir fluids more efficiently.

Which type of micromixer should I use? Use passive mixers for low-cost, disposable, or simple applications. Use active mixers when you need speed, precision, or dynamic control.