Hemza Berkani, Ph.D.

Researcher Edinburgh Napier University

What were the initial complexities or hurdles you encountered when designing this multi-layered microfluidic chip?

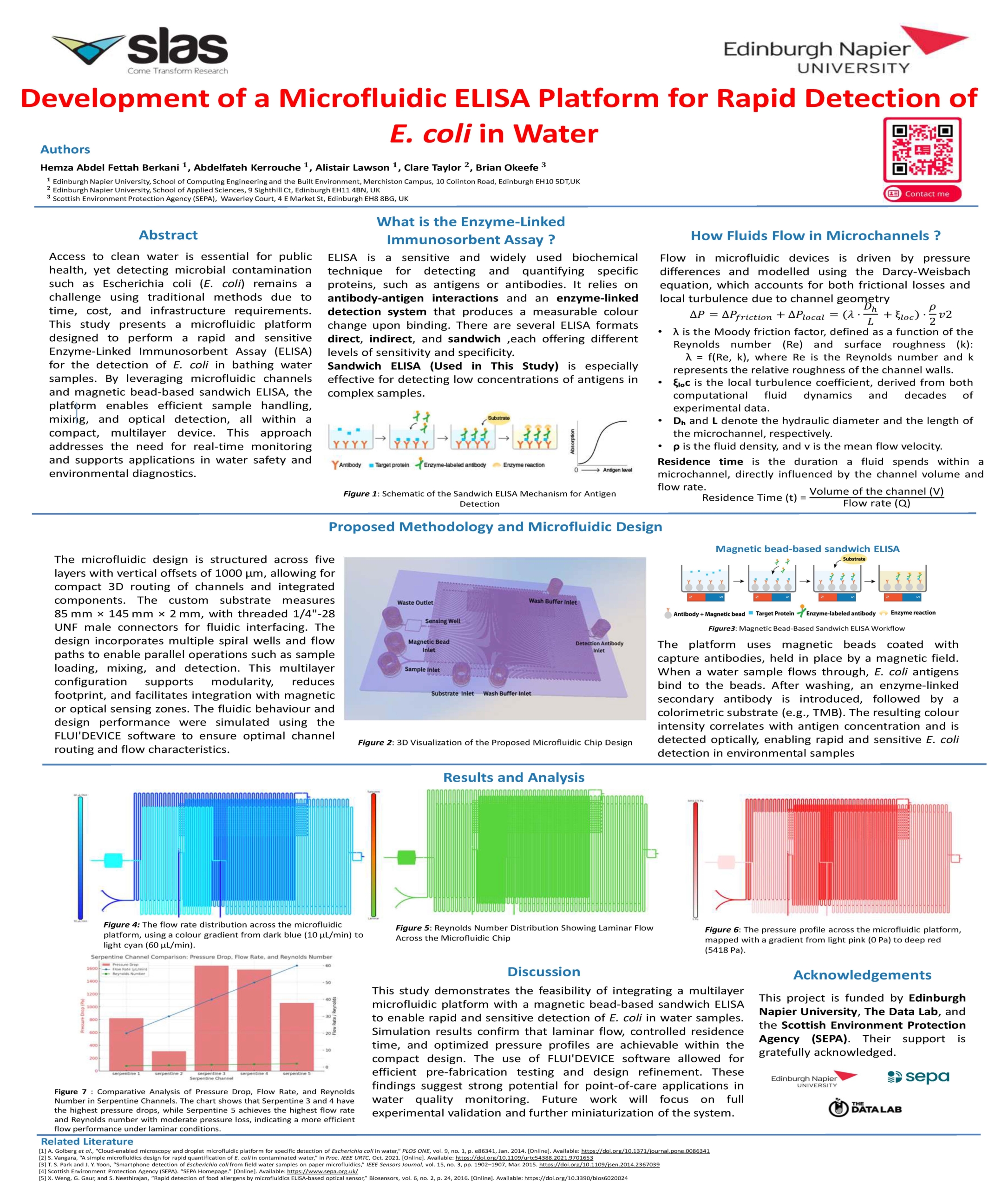

One of the main challenges I faced was managing the complexity of fluid flow across multiple interconnected layers, especially ensuring consistent mixing and incubation times for each reagent. Designing precise channel geometries that would accommodate laminar flow while maintaining the necessary reaction kinetics was also particularly tricky. Additionally, visualizing and optimizing the pressure and flow dynamics in a compact format was difficult using traditional CAD tools.

Before using FLUI'DEVICE, how did you approach microfluidic design and simulation, and what specific limitations or inefficiencies did you experience with those methods?

Prior to FLUI’DEVICE, I mainly relied on general-purpose CAD software for design and used COMSOL Multiphysics for simulations. While powerful, these tools required a steep learning curve, were time-intensive, and involved frequent back-and-forth between platforms. Any design iteration was tedious and often error-prone, especially when working with multiple design layers and small-scale geometries.

Could you elaborate on how FLUI'DEVICE specifically enabled this efficiency and refinement in your design process?

FLUI’DEVICE provided an intuitive, all-in-one platform that significantly accelerated the design-simulate-refine cycle. It allowed me to visually construct multi-layered chips with precise control over each component, and then immediately simulate parameters like flow rate, pressure drop, and Reynolds number without exporting to another tool. This immediate feedback helped me refine my design much faster and with greater confidence. The ability to simulate different experimental conditions also helped with fabrication errors.

How crucial were these specific simulation capabilities of FLUI'DEVICE (flow rate, Reynolds number, pressure profile) to ensuring the optimal performance and reliability of your device?

These simulation features were absolutely essential. For instance, the flow rate distribution (Figure 4) helped me verify that each channel delivered reagents evenly, while the Reynolds number analysis (Figure 5) confirmed laminar flow, critical for ELISA-based reactions. The pressure profile (Figure 6) ensured that there were no unintended flow imbalances or channel blockages. Having these insights early on allowed me to optimize both device geometry and operating parameters before moving to fabrication.

What would you say is the most significant value or benefit that FLUI'DEVICE brought to your research and why?

The most significant benefit was the ability to quickly iterate and validate designs with confidence. FLUI’DEVICE bridged the gap between conceptual design and experimental implementation by providing a simulation environment that is both accessible and scientifically robust. It helped streamline my workflow and ultimately improved the reliability and efficiency of my microfluidic ELISA platform. I would absolutely recommend it to other researchers, especially those who need rapid and accurate design validation.