Innovation Through Synergy: Eden Tech and IMT Evolving the Future of Microfluidics

Microfluidics is driving revolutionary progress in biotechnology, diagnostics, and materials science, ever hungry for platforms that deliver speed, flexibility, and reliability. Eden Microfluidics’ FLUI’DEVICE and IMT’s advanced microfluidic glass manufacturing come together in a unique collaboration that streamlines the journey from concept to production.

Why Microfluidic Collaboration Matters

Combining Eden’s intuitive FLUI’DEVICE online design tool with IMT’s high-performance biochips means researchers and engineers can translate ideas into functional prototypes, efficiently, accurately, and at any scale. The synergy between these platforms closes the gap between rapid digital design and high-end glass biochip production.

FLUI’DEVICE: Microfluidic Design Made Effortless

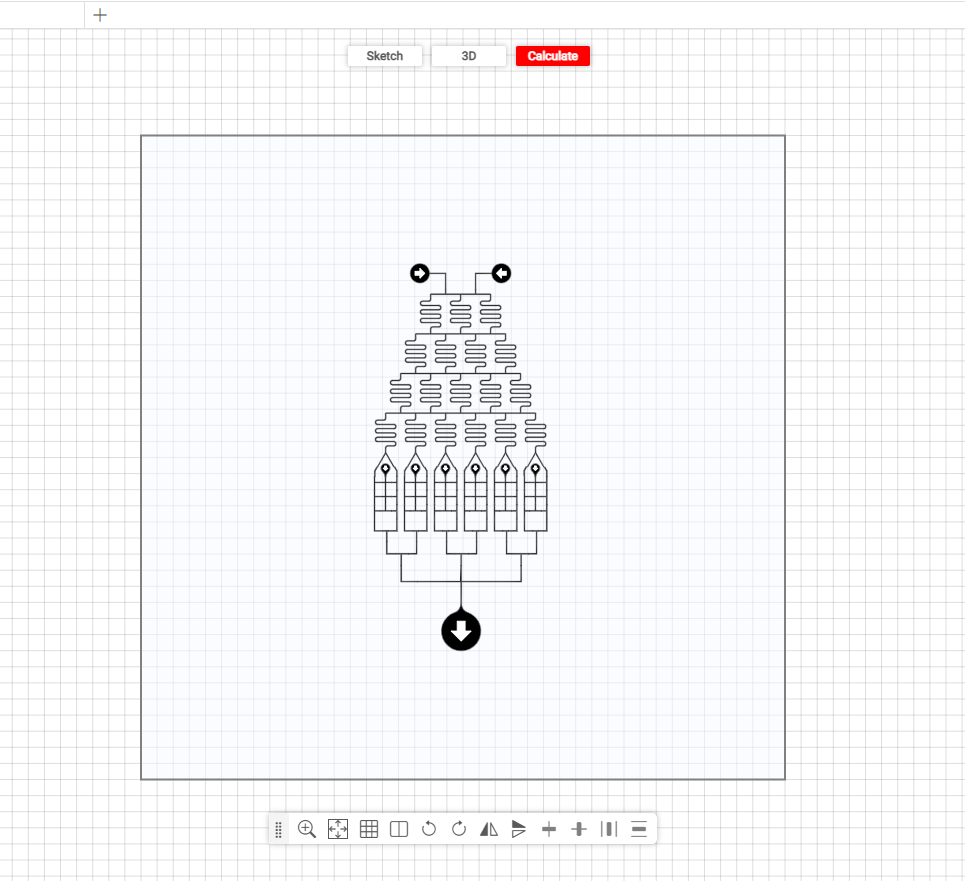

FLUI’DEVICE is an all-in-one microfluidic design platform, no complex software, no coding. With its drag-and-drop functionality, designers can build fluidic circuits from a comprehensive library, instantly run hydrodynamics simulations, and export their work in multiple formats suitable for prototyping or manufacturing (SVG, STL, DXF). Features include:

- Flow rate, pressure, and channel calculations

- Export options for direct mold fabrication or 3D printing

- Compatibility with established partners for seamless integration

This means moving from a digital model to a microfluidic device is faster, minimizes human error, and supports high-impact research across fields.

IMT: Where Optics meets Microfluidics

IMT offerslmicrofluidic foundry services for any kind of micro- and nanostructures on or in glass. Their customer-specific biochips and microfluidic flow cells are built for demanding applications in the Life Sciences and incorporate:

- Glass-based platforms for optimal optical performance

- Tailored multi-level channels for fluid handling

- Combination of microfluidic platforms with dielectric & metal layers

IMT’s manufacturing precision ensures the chips maintain tight tolerances down to the micron, ideal for integrating with CAD outputs from FLUI’DEVICE.

Seamless Integration: Digital to Physical

The collaboration prioritizes seamless translation of digital designs into functional prototypes. FLUI’DEVICE’s export features allow researchers to send validated designs directly to IMT’s fabrication teams, who then realize these projects with glass microfabrication or hybrid chip formats.

- FLUI’DEVICE provides instant feedback and simulation early in the design phase

- IMT’s engineering refines physical chips for robustness and reliability

Researchers gain peace of mind: their simulation-validated designs will function as intended, whether in diagnostics, organ-on-chip studies, or next-gen chemical assays.

From Design to Device: Integrating FLUI'DEVICE and IMT in Your Workflow

The real power of this collaboration lies in the seamless transition from the digital to the physical world. With FLUI’DEVICE, you can sketch, simulate, and export your microfluidic concept using a user-friendly platform, giving you instant insight into flow rates, pressure drops, and accurate dimensions, all optimized for manufacturability. IMT then puts your design into action, using their proven expertise to produce robust, reliable microfluidic chips and flow cells tailored to your specs.

Researchers, engineers, and innovators: you’re invited to discover how FLUI’DEVICE can supercharge your design process and how IMT can bring your ideas to life at scale. Explore each platform to see how simple it is to integrate digital design and precision fabrication into your own workflow, unlocking new possibilities for your lab, business, or academic project.

Visit Eden Microfluidics to try FLUI’DEVICE and connect with IMT to begin transforming your next microfluidic concept into a reality.