Oscar Zabaco Ph.D.

Freelance Bio-Device Consultant, Designer, and Manufacturer

How I Approach New Projects?

When tackling a new project, I prioritize understanding the underlying biology. This biological foundation is crucial for effectively applying engineering solutions.

After grasping the problem, I delve into project specifications and create preliminary sketches to brainstorm potential concepts. Collaborating closely with the client, we select the most promising direction.

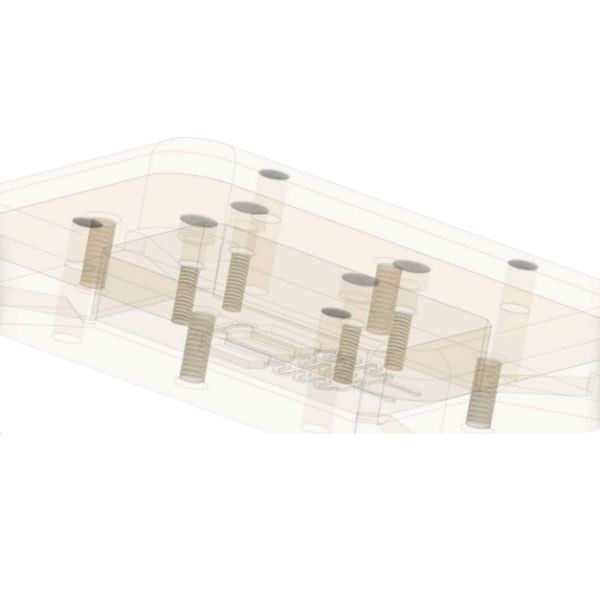

Next, I move on to CAD design, prototype manufacturing, and rigorous testing. Once validated, we proceed to final manufacturing. Throughout this process, open communication with the client is paramount.

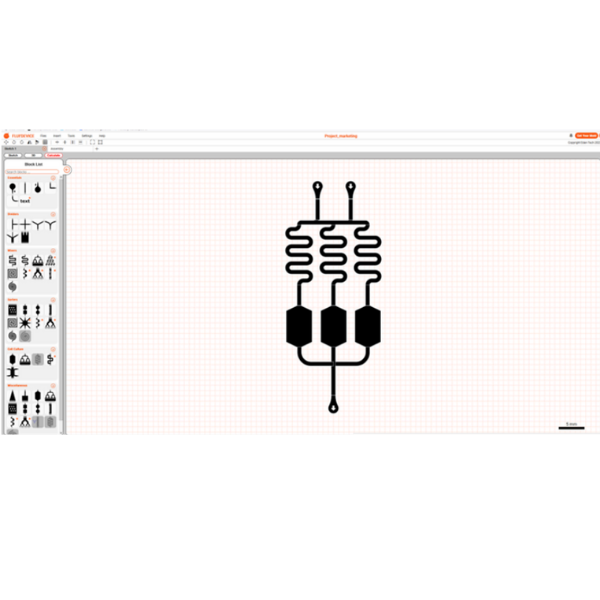

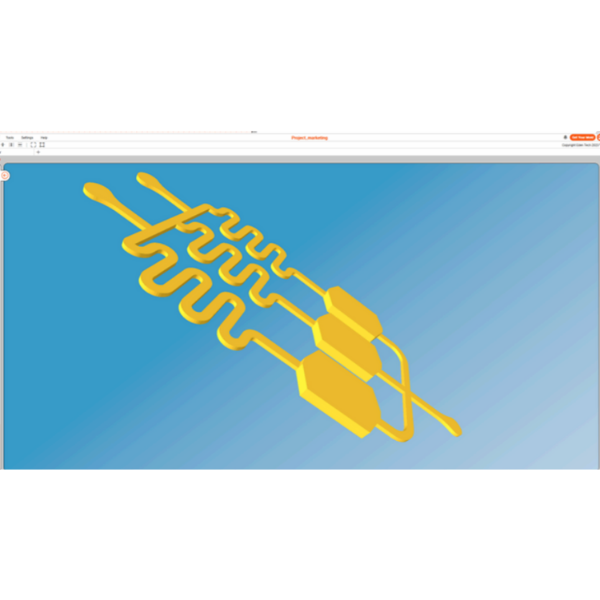

FLUI’DEVICE is an invaluable tool for designing microfluidic components and verifying pressures and flows. I export the designs to my 3D CAD software to complete the device design, including molds, tooling, and more.

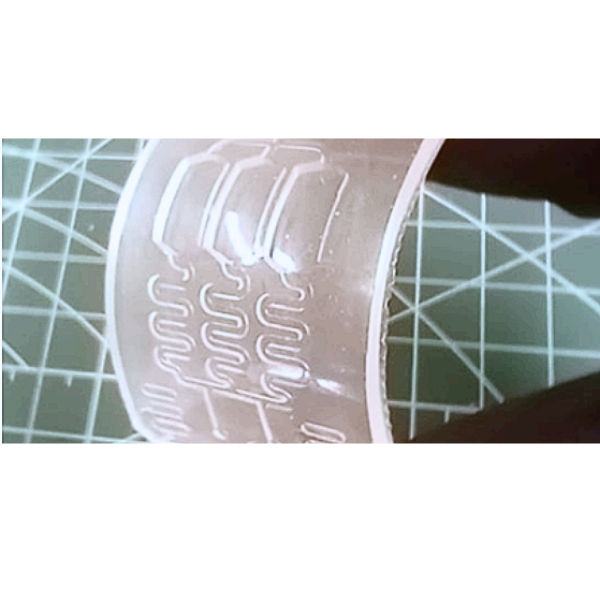

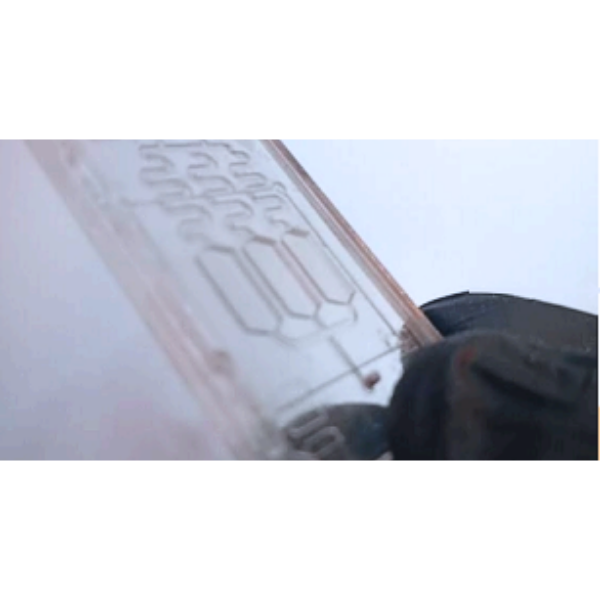

I’m a huge fan of Flexdym™!

Beyond its bonding capabilities, it offers numerous advantages like pre-production and production manufacturing (hot embossing & mold injection). Its versatility allows for combination with other materials (TPs and glass) and the integration of sensors, opening up endless possibilities.

Design for Prototyping vs. Manufacturing and Interface Considerations.

The Nuances of Design for Prototyping and Manufacturing Designing for prototyping and manufacturing are two distinct processes.

When prototyping, the focus is on testing the concept. However, designing for manufacturing requires considering factors like feasibility, cost-effectiveness, and reproducibility.

This demands expertise in various manufacturing strategies and a deep understanding of equipment capabilities.

Neglecting these aspects in the early stages can lead to costly rework.

The Importance of Interface Design

Interface design is often overlooked, even in projects primarily involving fluidics. When sensors, actuation systems, or optics are included, interface design becomes even more critical.

It’s essential to consider the device’s interface from the outset to ensure seamless integration and functionality.