Droplet-Microfluidics: The Potential of Flexdym™

Introduction: The Tiny World of Droplet Microfluidics

Droplet microfluidics, a subset of microfluidic technologies has reshaped biology, chemistry, and beyond. This innovative field enables the precise manipulation of tiny droplets as miniature reaction chambers. Driving breakthroughs in diagnostics, drug discovery, and environmental science. Materials have always been critical to the development of these devices. While traditional options like PDMS, glass, and thermoplastics have dominated, Flexdym™, a flexible, transparent, and biocompatible thermoplastic elastomer, has brought transformative capabilities to the field.

Let’s dive into the fascinating world of droplet microfluidics, and explore why Flexdym™ can make an impact in this exciting domain.

What Is Droplet Microfluidics?

At its core, droplet microfluidics involves the generation, manipulation, and analysis of tiny droplets within a carrier fluid. These droplets can serve as miniature reaction chambers, enabling experiments with unparalleled precision and throughput. Its correct operation lies in the design and materials of the device networks of microscale channels, where the droplets form and flow.

The growing popularity of droplet microfluidics is reflected in the scientific literature. According to recent analyses:

- Droplet microfluidics now constitutes about 15% of all microfluidics-related publications. Up from just 5% fifteen years ago.

- While PDMS continues to dominate due to its established presence, materials like fluoropolymers and 3D-printed polymers are gaining traction for their unique properties.

Flexdym™, although a recently introduced product, can carve out a niche for itself by addressing the unmet needs of both researchers and industrial users.

Polymers in Droplet Microfluidics: The Traditional Players

Over the years, researchers have experimented with various materials for fabricating microfluidic devices. Each comes with its own advantages and challenges:

PDMS (Polydimethylsiloxane):

- Pros: Flexible, transparent, biocompatible, permeable to the gas, and easy to mold.

- Cons: Absorbs small hydrophobic molecules, and their surface properties degrade over time.

Glass:

- Pros: Chemically resistant, optically clear, and reusable.

- Cons: Expensive and labor-intensive to fabricate, limiting scalability.

Thermoplastics (e.g., PMMA, COC):

- PMMA: Offers rigidity and optical transparency but is not compatible with many solvents.

- COC: Known for chemical resistance and biocompatibility but requires hydrophilic surface treatments for aqueous applications.

These materials have played a fundamental role in microfluidic research. But each has limitations, particularly in the balance between ease of fabrication, durability, and application versatility.

Flexdym™: a new polymer for Droplet Microfluidics

Flexdym™ can renovate the landscape of droplet microfluidics. This thermoplastic elastomer combines some of the best attributes of traditional materials, while addressing some of their drawbacks.

Easy Fabrication:

Flexdym™ eliminates the need for plasma bonding, simplifying assembly. Moreover, it supports rapid prototyping through hot embossing and injection molding, enabling high-throughput production of devices.

Performance:

This material shows stable hydrophilicity for up to a few days post-treatment, excellent optical clarity, and resistance to the adsorption of small molecules. These properties ensure consistent, high-quality droplet formation.

Versatility Across Applications:

Whether it’s biological assays, organ-on-chip models, or environmental diagnostics, Flexdym™ offers adaptability, making it ideal for varied fields.

Practical Performance: Experiments with Flexdym™

Eden Tech has performed a study to evaluate the potential of Flexdym™ in droplet microfluidics. The experiments focused on optimizing Flexdym™ chip fabrication, and testing its ability to generate water-in-oil (w/o) droplets. The results demonstrate Flexdym™ adaptability, efficiency in droplet formation, and stability.

Fabrication of Flexdym™ Chips

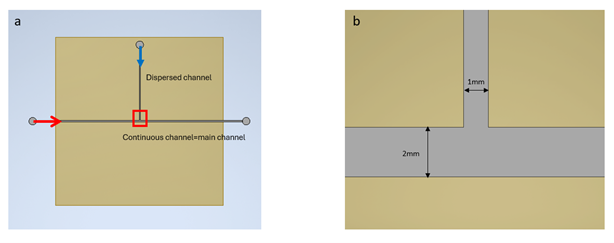

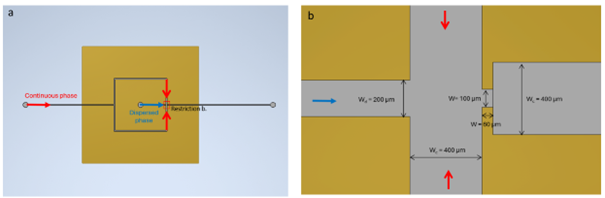

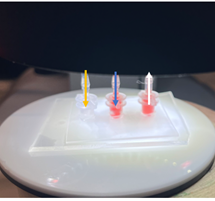

Flexdym™ sheets (1.2 mm thick) were molded using the Sublym™ hot-embossing machine (optimized parameters: time 600sec, temp 100°C, 5mm spacers) to fabricate the microfluidic devices. The designs chosen for the study were a T-junction and a Flow Focus (Figures 1 and 2). The molds used for hot embossing were either a 3D printed (printed with Figure 4 Standalone printer, HI TEMPS 300-AMB resin, 50 µ-resolution), or a NOA*. Thermal bonding at 70°C for 120 seconds (with 5.7 mm spacers) was used to bond the hot embossed layer of Flexdym, to another 1.2 mm sheet, in order to fabricate the final microfluidic device (figure 3).

Inlets and outlets were integrated directly into the mold to optimize production efficiency. This approach, better described in the application note Optimizing Microfluidics – The Advantages of Piercing Inlets and Outlets Directly During Molding eliminated manual drilling, significantly improving production speed and accuracy.

Let’s dive into the fascinating world of droplet microfluidics and explore why Flexdym™ can make an impact in this exciting domain.

Droplet microfluidics, a subset of microfluidic technologies, has reshaped biology, chemistry, and beyond. This innovative field enables the precise manipulation of tiny droplets as miniature reaction chambers. Driving breakthroughs in diagnostics, drug discovery, and environmental science. Materials have always been critical to the development of these devices. While traditional options like PDMS, glass, and thermoplastics have dominated, Flexdym™, a flexible, transparent, and biocompatible thermoplastic elastomer, has brought transformative capabilities to the field.

Droplet Formation using Flexdym chips

Before going deep in the experimental section, we are going to review the main factors that influence droplets generation in microfluidics. Droplet size and generation frequency in microchannels are influenced by a complex interplay of geometric parameters, flow parameters, and fluid properties. More in details:

Flow parameters:

Such as the ratio of the flow rate of the dispersed phase (Qd), and the continuous phase(Qc). With the increase of this ratio (Qc/Qd), the diameter of the droplets increases for the same geometry. For instance, a higher flow rate of the dispersed phase compared to the continuous phase, results in larger droplets.

Fluid properties:

Such as viscosity and interfacial tension. Surfactants reduce the interfacial tension between the dispersed phase and the continuous phase. This reduction in interfacial tension facilitates the formation of droplets. Since it requires less energy to break the interface between the two fluids; so it is important the optimize the quantity of the surfactant used in the experiment.

Another important parameter correlated to the fluid properties is the capillary number (Ca), which relates to viscosity, velocity, and interfacial tension. Ca is a dimensionless parameter that influences droplet size. This decreases with increasing Ca. This is because a higher capillary number indicates a higher viscous force, which facilitates droplet breakup. The viscosity ratio (λ) between the dispersed phase and the continuous phase also influences droplet size. Smaller droplets are generated with a lower λ in all Ca studied.

Geometric parameters:

Droplet size is significantly affected by the geometric parameters, especially the channel width at the disruption point. Microchannels with constriction can generate smaller droplets than traditional T-junction microchannels. This is because the constriction increases the fluid velocity and the shear effect on the dispersed wire, making it easier to break the droplets into smaller droplets.

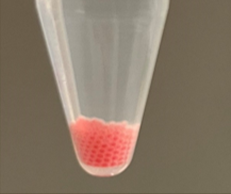

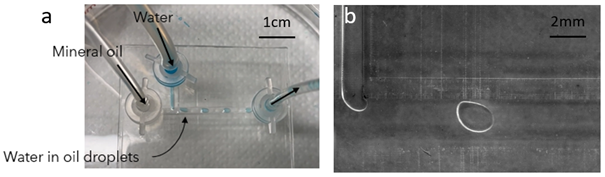

In our study, w/o droplets were generated (Figure 4) using deionizer water (as dispersed phase) and mineral oil (as continuous phase) with varying the surfactant (Span80) concentrations from 0.5% to 10%, in order to determine the best concentration for droplets formation. In the following section, the impact of 3 main elements is going to be discussed and analyzed: 1. Flow parameters, 2. Surfactant concentration and 4. geometry.

1. The impact of the flow parameters

The flow rate ratio is a crucial factor that influences both the size and generation rate of droplets in microfluidics. A higher flow ratio (Qc/Qd) generally leads to the formation of smaller droplets. This is due to the increased shear force exerted by the continuous phase on the dispersed phase, which facilitates its breakup into smaller droplets. On the contrary, a lower ratio leads to the formation of larger droplets.

On the other hand, a higher Qc/Qd generally leads to a higher droplet generation rate. This is because a higher flow rate of the continuous phase pushes the dispersed phase through the junction, at a higher velocity, producing droplets at a faster rate. In comparison, lower Qc/Qd leads to a lower droplet generation rate. This is because the dispersed phase flows more slowly through the junction, resulting in droplets forming at a slower rate.

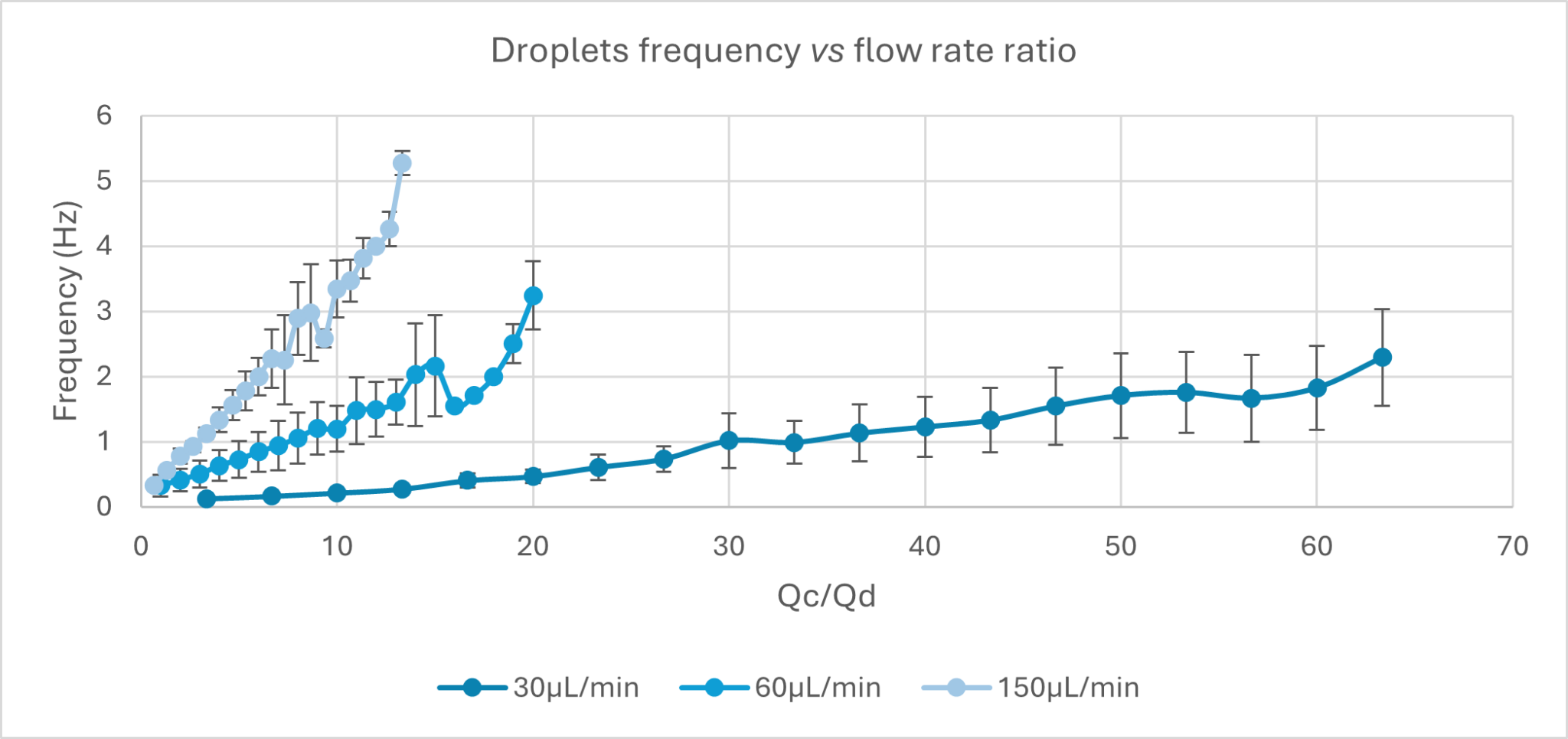

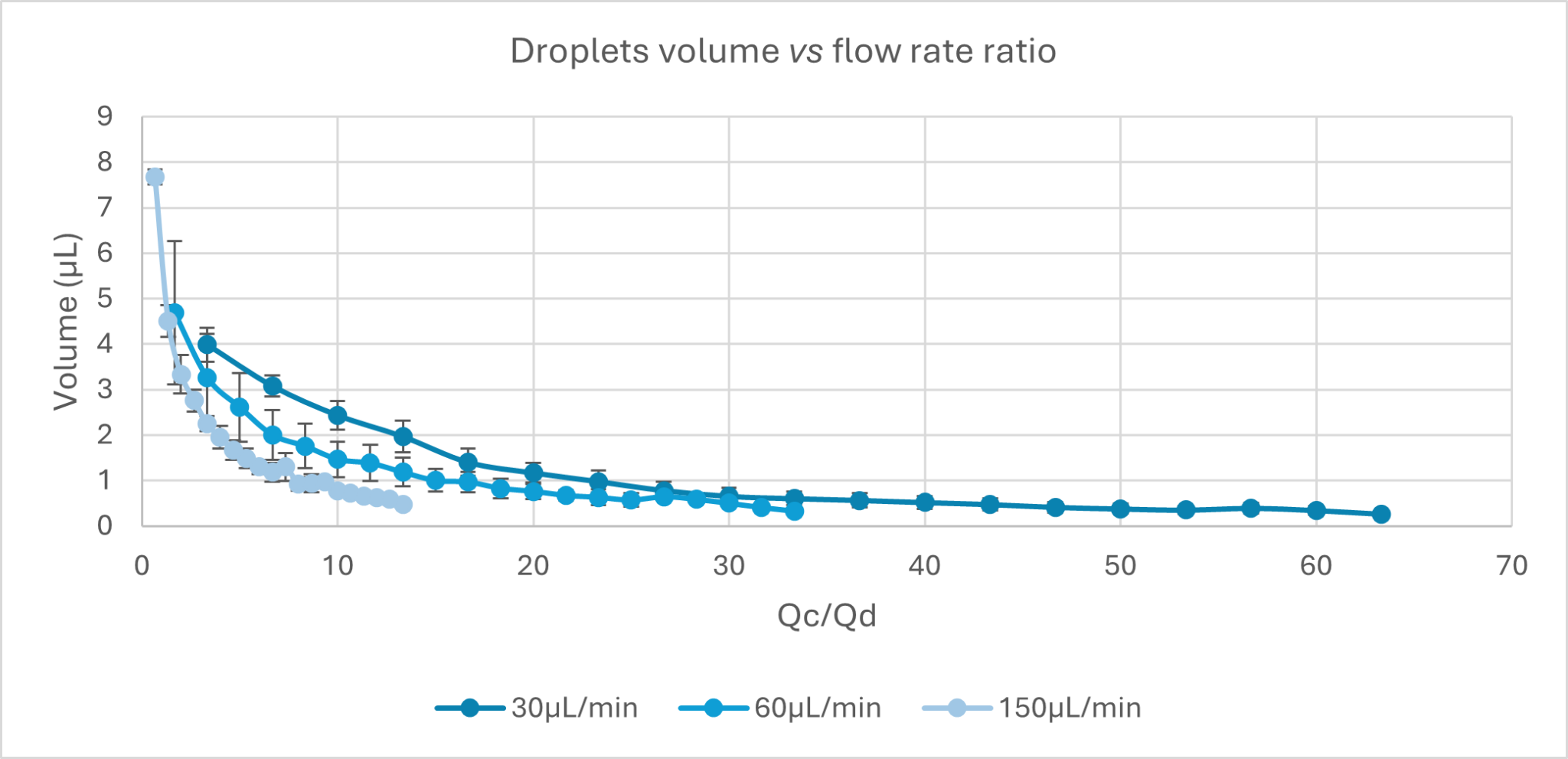

In agreement with the literature, the conducted tests have shown that increasing Qc with respect to Qd reduces the droplet size and increases the frequency, with the system reaching a plateau at high flow rates. This is shown in Figures 5 and 6.

The droplets volume was calculated by ![]() with N the number of droplets per minutes, when the frequency of droplets formation allows an easy counting. Otherwise, the diameter is measured using ImageJ software, and in this case the number of droplets per minute is calculated as follow:

with N the number of droplets per minutes, when the frequency of droplets formation allows an easy counting. Otherwise, the diameter is measured using ImageJ software, and in this case the number of droplets per minute is calculated as follow: ![]() . This method can only be used when the droplets are spherical, which is the case. The frequency in Herz was calculated

. This method can only be used when the droplets are spherical, which is the case. The frequency in Herz was calculated ![]() .

.

In summary, we were able to produce droplets in Flexdym chips by changing the flow rate ratio. Flexdym chips were able to withstand pressure of 2Bar and at the same time the mineral oil didn’t provoke any delamination effect neither any Flexdym deformation.

2. The impact of the Surfactant concentration

Surfactant concentration in a microfluidic system significantly influences the frequency and size of droplets. Mainly by modifying the interfacial tension between the two liquid phases. Higher concentrations of surfactant generally reduce the interfacial tension, making it easier for droplets to form. In general, a higher concentration of surfactant leads to smaller droplet sizes. This is because a lower interfacial tension allows the continuous phase to break the dispersed phase more easily. Resulting in the formation of smaller droplets. On the contrary, low concentrations of surfactant can lead to the formation of larger droplets, due to higher interfacial tension.

The effect of surfactant concentration on droplet frequency is more complex and, as been said, may depend on other factors, such as flow ratio and device geometry. However, in general, a lower interfacial tension due to a higher surfactant concentration may facilitate a higher droplet generation frequency. Since the dispersed phase can be broken up more rapidly by the continuous phase.

In our study, it has been demonstrated that at low concentration (0.5%) of surfactant, droplets were large (up to 14 µL) and formed slowly (3 Hz), in contrast at concentration of 2%, efficiency improves significantly. Producing smaller droplets (~1 µL or less) at a higher frequency (>100 Hz).

It is important to remember that the surfactant concentration must be carefully optimized. Too low concentration may not be sufficient to stabilize the droplets, leading to inconsistent droplet formation or droplet coalescence. Too high concentration may lead to the formation of emulsions instead of discrete droplets, hindering the generation of controlled droplets. We noted in our study, that increasing the concentration up to 5% slightly reduces droplet size and further increases frequency. Making it the optimal concentration for stable (figure 7) and high frequency droplet production. At higher surfactant concentrations (7%-10%), the results were inconsistent (not shown) due to droplets coalescence and aggregate formation, that disrupted the normal droplet formation.

Also for the study of the surfactant concentration effect on droplets formation, Flexdym chips have been used, and no major deformation has been notice while changing the concentration of the surfactant in the several experiments.

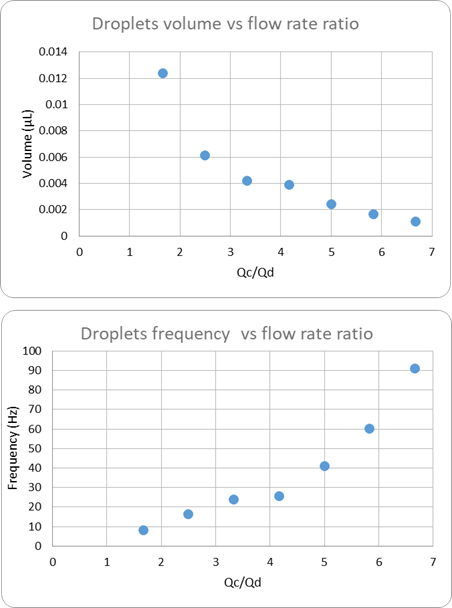

3. The impact of geometry

The impact of geometry on the generation rate and droplets size in microfluidic devices is significant. Several studies have shown how the shape and size of the microfluidic channel can influence the way fluids interact. And consequently, the size and frequency of droplets generated. Microchannels with a constriction, such as the flow focusing design showed in figure 2, can generate smaller droplets than traditional T-junction microchannels (figure 1). This is because the constriction increases the fluid velocity and the shear effect on the dispersed wire, making it easier to break the droplets into smaller droplets. On the other hand, channel geometry can also influence the droplet generation rate. Indeed, a narrower constriction can lead to a higher droplet generation rate, as the dispersed phase is pushed through the junction at a higher velocity.

For this study we conducted different experiments with both design (figure 1 and 2) and we observed that the droplet volume decreases sharply. While increasing flow rate ratio (Qc/Qd), due to the larger channel dimensions (mm scale) in the T-junction design. The smallest droplets were around 0.16 µL, and the frequency about 3 Hz (180 droplets/min), which is quite a low value. In contrast, with the Flow Focusing geometry we were able to produce smaller droplets (1 nL, ~ five times smaller than T-junction) due to narrower channels.

Moreover, this geometry promotes rapid droplet breakup, achieving a much higher frequency of up to 100 Hz (5464 droplets/min). Figure 8 shows the obtained results. The meaning of this experiment was to demonstrate that even with smaller geometry it’s possible to obtain smaller droplets. And also, increase their production frequency using Flexdym, thanks to its capability of withstanding very high pressure.

In these experiments the flow rate range (from 1 to 6) was smaller compared to the one tested in the first experiments. But it is important to highlight that the length of the whole experiment was kept the same as for the one carried out with the T-junction. Simply by increasing the testing time of each flow rate.

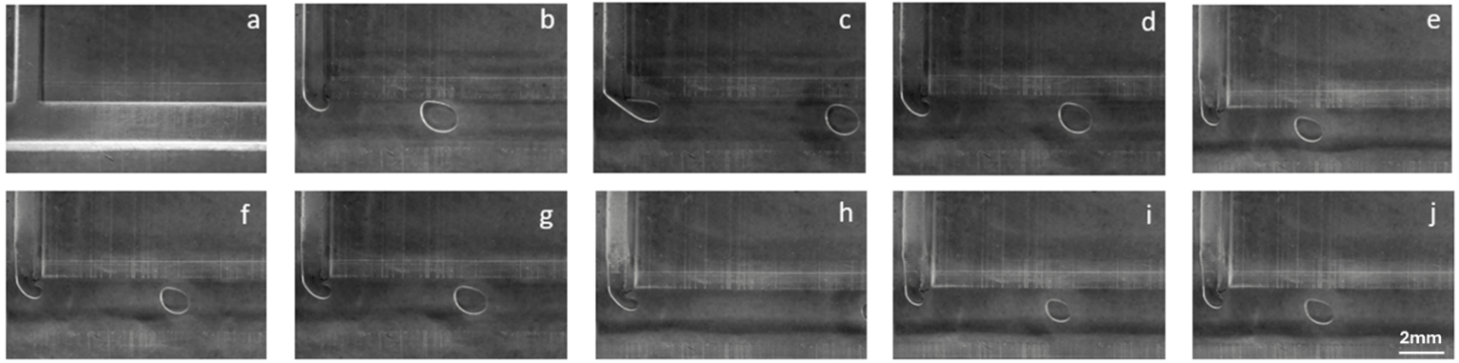

Long term experiment

Once we proved the potential of Flexdym in fabricating microfluidic devices for the production of w/o droplets, we explored the possibility of conducting long experiments, to test the responsiveness of Flexdym to mineral oil. The experiment has been left running for 8 hours using the following parameters: Qc=500µL/min, Qd=30µL/min, 5% of span80. A record of 2 min each 30 minutes have been done under the optical microscope to check if there were any change in the structure, or issue in terms of bonding. This experiment was conducted using the T-junction design (figure 9) and the water was doped with a blue food colorant, to facilitated the observation.

No structural degradation of Flexdym was observed during the extended use of mineral oil. This compatibility is an important aspect of the use of Flexdym in droplet-microfluidics. It will ensure reliability in various applications, especially encapsulation.

The future of synergy droplet-microfluidics & Flexdym™

The future of the synergy between droplet microfluidics and Flexdym™ looks bright, thanks to the unique properties of this material, and the growing applications of droplet microfluidics in different fields.

Flexdym™, being a flexible, transparent, and biocompatible thermoplastic elastomer, is particularly suitable for the fabrication of microfluidic devices for droplet generation. Its properties allow ease of manufacturing, strength, and plasma-free bonding (Flexdym™ is robust and reliable even at high flow rates), optical transparency, low cost, and ease of use.

The combination of these properties with the advantages of droplet microfluidics, such as reaction isolation, precise control of droplet size, and high throughput, opens the way to numerous future applications:

Cell Encapsulation:

The synergy between Flexdym™ and droplet microfluidics could lead to more efficient and automated systems for the production of cell microcapsules for biomedical applications, such as cell therapy and tissue engineering.

Point-of-care diagnostics:

The ease of fabrication and biocompatibility of Flexdym™, combined with the versatility of droplet microfluidics, make it an ideal candidate for the creation of rapid and portable diagnostic devices.

Drug screening:

Droplet microfluidics is already used for high-throughput drug screening on single encapsulated cells. The use of Flexdym™ could simplify the production and customization of these devices, accelerating the discovery of new drugs and the development of personalized therapies.

Conclusion

In conclusion, the synergy between droplet microfluidics and Flexdym™, represents a promising frontier in the field of microfluidics. Optimization of the manufacturing process, development of new surfactants, and integration with other technologies will be essential to unlock the full potential of this combination. Also translate it into innovative and impactful applications in different fields. Such as biomedicine, diagnostics, and drug discovery.

References

- Materials and Methods for Droplet Microfluidic Device Fabrication (2022).

- Internship Report on Flexdym™ Microfluidics Applications (2024).