Deterministic Lateral Displacement (DLD) in Microfluidics: Principles, Applications, and Design

What is Deterministic Lateral Displacement (DLD)?

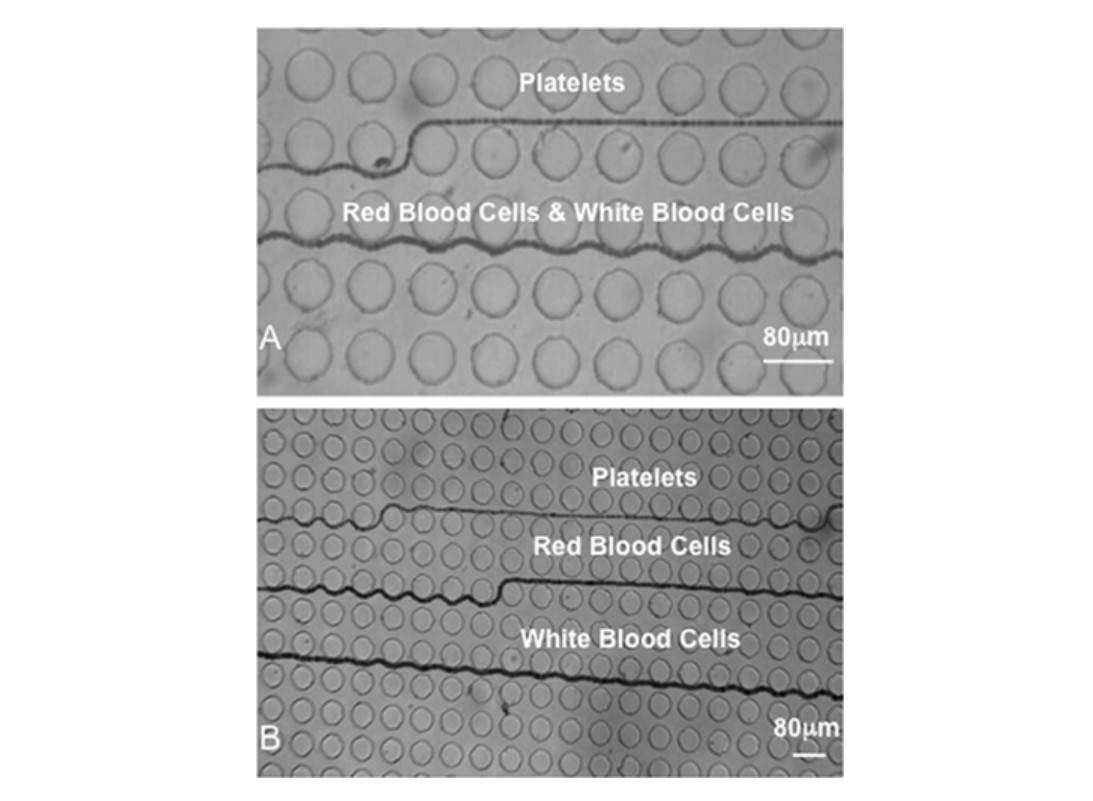

Deterministic lateral displacement (DLD) is a microfluidic technique used to separate particles, cells, or biomolecules based on their size with high precision and without labeling. This technique relies on laminar flow behavior and an array of micro-pillars to guide particles along specific trajectories.

Originally introduced by Huang et al. in 2004, DLD has become a foundational technology in microfluidics due to its deterministic nature, where every particle follows a predictable path based on its size relative to the device’s geometry.

How Does DLD Work?

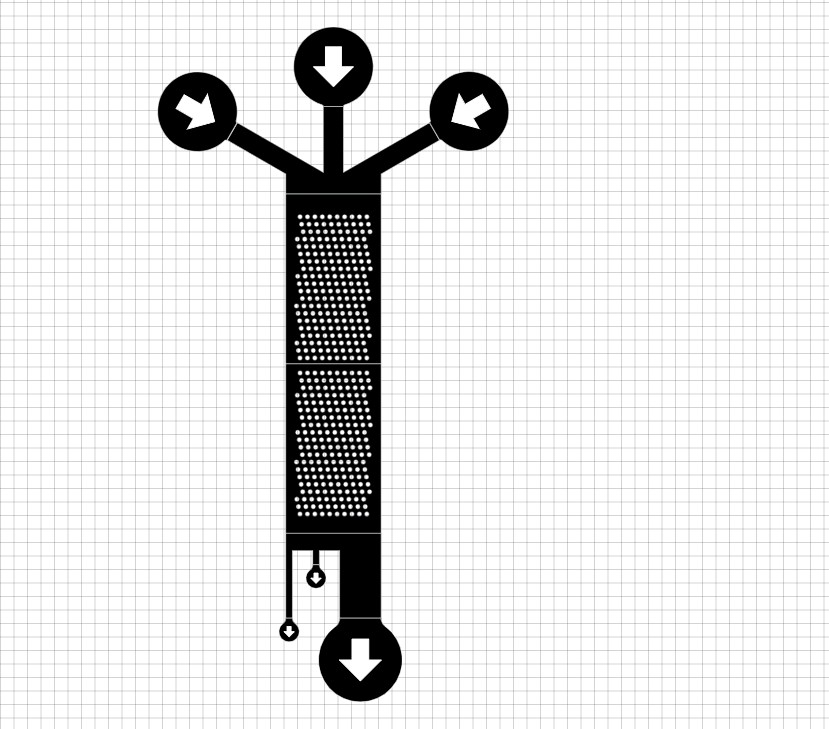

A typical DLD device consists of a periodic array of micro-posts arranged at an angle to the main flow direction. As fluid flows through the array:

Small particles (smaller than a critical diameter, Dc) follow the flow streamlines and move in a zigzag pattern through the gaps between pillars.

Large particles (larger than Dc) interact with the posts and are displaced laterally in a different trajectory—a process known as the “bumping mode”.

The critical diameter is determined by the gap size, post size, and array geometry. It can be tuned precisely to isolate particles within nanometers of difference.

🔬 Reference: Inglis, D. W. et al., “Critical particle size for fractionation by deterministic lateral displacement,” Lab Chip, 2006, 6, 655–658. https://doi.org/10.1039/B513215C

Core Parameters in Designing a DLD Device

When designing a DLD device, key parameters must be considered:

| Parameter | Description |

|---|---|

| Post diameter (D) | Affects hydrodynamic interactions |

| Gap between posts (G) | Determines the fluid streamlines |

| Row shift fraction (ε) | Governs the angle of the array and critical diameter |

| Channel height (H) | Important for 3D confinement and flow control |

| Critical diameter (Dc) | Target size for separation |

According to the widely cited design rules by Davis et al. (2014), the critical diameter Dc can be approximated by:

Dc = 1.4 × G × ε⁰·⁴⁸

Where:

G is the gap between pillars

ϵ is the row shift fraction

📚 Reference: Davies, H. T. et al., “Deterministic lateral displacement: Theoretical analysis and experimental validation”, Lab Chip, 2014, 14, 4138–4146. https://doi.org/10.1039/C4LC00939H

Key Applications of DLD in Life Sciences and Industry

DLD technology is used in a wide range of biological, clinical, and industrial applications:

1. Blood Plasma Separation

Rapid, label-free separation of red blood cells (RBCs) from plasma.

Enables point-of-care diagnostics and wearable biosensors.

2. Circulating Tumor Cell (CTC) Isolation

Enrich rare cancer cells from whole blood for early cancer detection and monitoring.

3. Exosome and Extracellular Vesicle (EV) Isolation

DLD arrays can sort extracellular vesicles based on size, enabling high-purity EV collection.

4. Pathogen Detection

Separate bacteria or parasites from whole blood or environmental samples.

5. Industrial Particle Sorting

Used in food, chemical, and environmental industries to sort microplastics, spores, or colloidal particles.

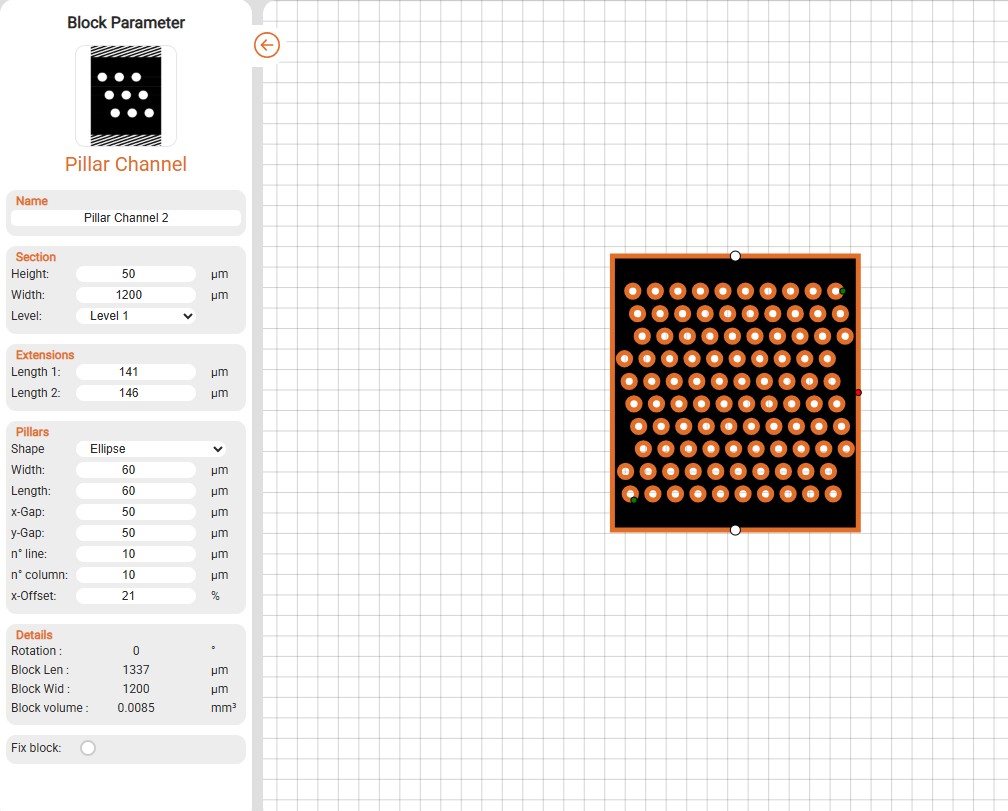

Designing Your Own DLD Device with FLUI'DEVICE

Designing a DLD microfluidic device may sound complex, but FLUI’DEVICE makes it accessible, even for non-experts.

With FLUI’DEVICE, you can:

– Use DLD-specific building blocks

Design DLD pillar arrays with built-in parameter inputs (post diameter, gap, array angle, number of rows, etc.) in seconds.

– Simulate flow patterns

Visualize flow, pressure drop, hydraulic resistance, Reynolds numbers etc…

– Export in STL/DXF/SVG

Once designed, export your DLD chip in formats compatible with 3D printing or soft lithography, for example. You can also send us your STL file for high-resolution 3D printing.

DLD Design Example Using FLUI'DEVICE

Let’s say you want to isolate particles larger than 6 µm from a sample. Here’s a quick design approach in FLUI’DEVICE:

Choose the shape of your post (polygon, elliptical, stadium…)

Set the gap (G) between pillars to 10 µm

Adjust pillar number, spacing, offset and channel width

Simulate and refine the design based on flow behavior

No coding. No CAD skills. Just fast, reproducible microfluidic design.

Try FLUI'DEVICE Now and Start Designing Your DLD Microfluidic Chip

Want to prototype your own DLD chip today?

Start designing for free on FLUI’DEVICENeed a high-resolution mold? Get it printed with FLUI’MOLD

References

Huang, L. R. et al., “Continuous Particle Separation Through Deterministic Lateral Displacement”, Science, 2004.

Inglis, D. W. et al., “Critical particle size for fractionation by deterministic lateral displacement”, Lab Chip, 2006.

Davies, H. T. et al., “Deterministic lateral displacement: Theoretical analysis and experimental validation”, Lab Chip, 2014. https://doi.org/10.1039/C4LC00939H

Loutherback, K. et al., “Deterministic separation of cancer cells from blood at 10 mL/min”, Lab Chip, 2012.

Zheng, S. et al., “Membrane microfilter device for selective capture, electrolysis and genomic analysis of human circulating tumor cells”, Nature Biotechnology, 2011.

Final Thoughts

Deterministic lateral displacement is one of the most elegant and effective size-based separation methods in microfluidics. Whether you’re working on cell sorting, EV research, or microplastics filtration, DLD can offer unparalleled precision and FLUI’DEVICE helps you get there faster.

Design smarter. Prototype faster. Join the microfluidic revolution with FLUI’DEVICE.