3D Cell Culture Breakthrough: Scalable Vascularized Tissues Using Flexdym™ (2024 Study)

What Is 3D Cell Culture?

3D cell culture is a technique that grows cells in three dimensions to better replicate in vivo tissue environments. It is now essential for applications in tissue engineering, drug screening, and regenerative medicine, offering more accurate physiological models than traditional 2D cultures.

3D cell culture is rapidly becoming the gold standard in tissue engineering, drug testing, and regenerative medicine. Yet, most platforms still rely on PDMS-based systems that limit scalability and tissue recovery. In this article, we highlight a breakthrough 2024 study showing how Flexdym™, a biocompatible thermoplastic elastomer, enables the creation and harvesting of vascularized tissues offering a powerful alternative to traditional 3D cell culture methods.

Challenges of Traditional 3D Cell Culture Platforms

Most microfluidic 3D cell culture systems rely on PDMS (polydimethylsiloxane). While useful for prototyping, PDMS presents serious limitations:

Poor scalability due to soft lithography

Absorption of hydrophobic drugs

Gas permeability causing assay artifacts

Irreversible bonding, making tissue retrieval difficult

These drawbacks limit reproducibility, hamper clinical translation, and complicate real-world applications.

New to microfluidics? Read our beginner’s guide to microfluidics here.

Why Flexdym™ Is a Game-Changer in 3D Cell Culture

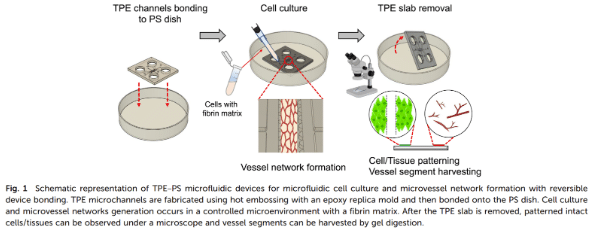

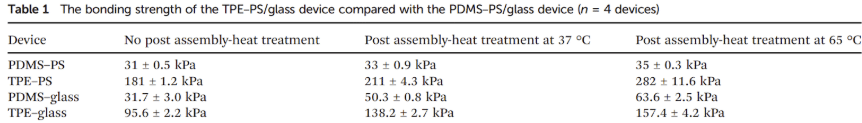

To address PDMS limitations, researchers developed a hybrid thermoplastic elastomer (TPE) microfluidic platform using Flexdym™. This SEBS-based material enables:

– 6× stronger bonding with polystyrene (PS) compared to PDMS

– Reversible bonding, enabling non-destructive access to tissues

– Minimal protein and drug absorption

– Compatibility with high-throughput manufacturing methods

These properties make Flexdym™ ideal for building scalable, reproducible, and ethical 3D cell culture models.

Case Study: Vascularized Tissues Using Flexdym Microdevices

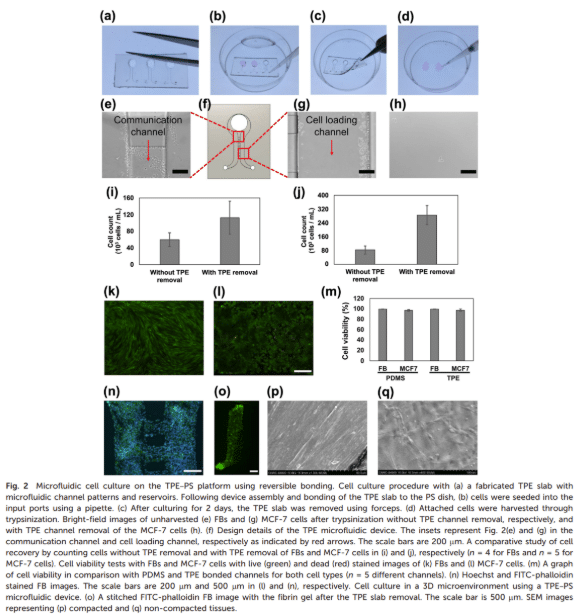

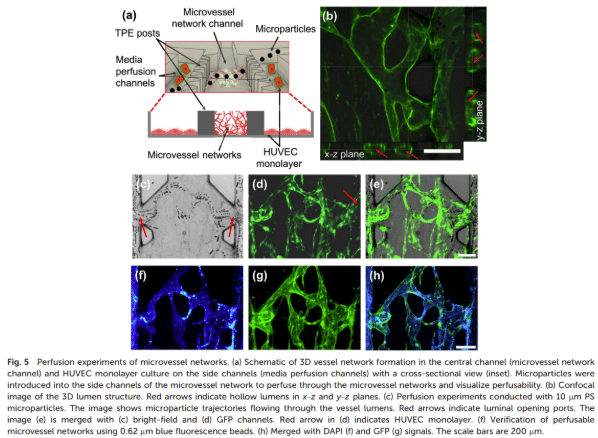

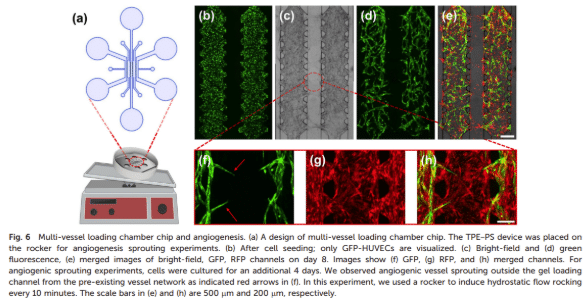

A 2024 study engineered vascularized tissues by co-culturing GFP-HUVECs and RFP-labeled lung fibroblasts inside fibrin gels within a Flexdym–PS device. Key results over 8 days:

14%–36% increase in vessel coverage

Total network length: 22 mm with lumens verified via confocal imaging

Leak-free perfusion of 0.62 µm bead : confirming vessel functionality

These networks closely mimic real microenvironments, ideal for drug testing and regenerative applications.

Comparing PDMS vs Flexdym for 3D Cell Culture

| Feature | PDMS | Flexdym™ |

|---|---|---|

| Drug absorption | High | Very Low |

| Scalability | Low | High (thermoforming) |

| Bonding | Irreversible | Reversible & Irreversible |

| Biocompatibility | Moderate | Excellent |

| Tissue recovery | Destructive | Non-destructive |

Non-Destructive Tissue Harvesting Enabled by Flexdym

Unlike PDMS devices, Flexdym allows the top layer to be removed post-culture without damaging the tissue. This unique feature supports:

Enzymatic digestion and omics analysis

Histological examination

Direct transplantation

Reduction in animal testing and in vivo harvesting

📚 This is the first published method enabling true non-destructive tissue recovery in bonded microfluidic systems.

Applications and Future Outlook

Flexdym-based 3D cell culture systems support:

Organ-on-chip model development

Drug permeability and toxicity assays

Regenerative tissue engineering

Tumor microenvironment simulation

These platforms align with industrial and academic needs for scalable, reproducible, and animal-free models.

Q&A 3D Cell Culture and Flexdym™

What is 3D cell culture and why is it important?

It enables cells to grow in all directions, better mimicking human tissue. This improves the relevance of drug studies and disease models.

Why is PDMS problematic for 3D cell culture?

It absorbs small molecules, is hard to scale, and makes tissue harvesting destructive due to permanent bonding.

What makes Flexdym better than PDMS?

Flexdym enables reversible bonding, low absorption, and non-destructive harvesting, ideal for advanced tissue models.

Can Flexdym be used for organ-on-chip applications?

Absolutely. Flexdym supports ethical, scalable organ-on-chip development and integration into industrial workflows.

References

Moon, B.-U., Li, K., Malic, L., Morton, K., Shao, H., et al. (2024). Reversible bonding in thermoplastic elastomer microfluidic platforms for harvestable 3D microvessel networks. Lab on a Chip, 24, 4948–4961. https://doi.org/10.1039/d4lc00530a