Discover The New Era Of Mold Microfabrication

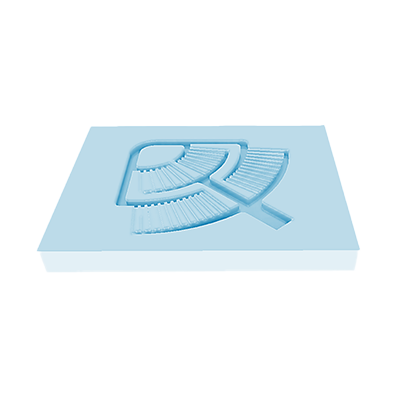

True 3D

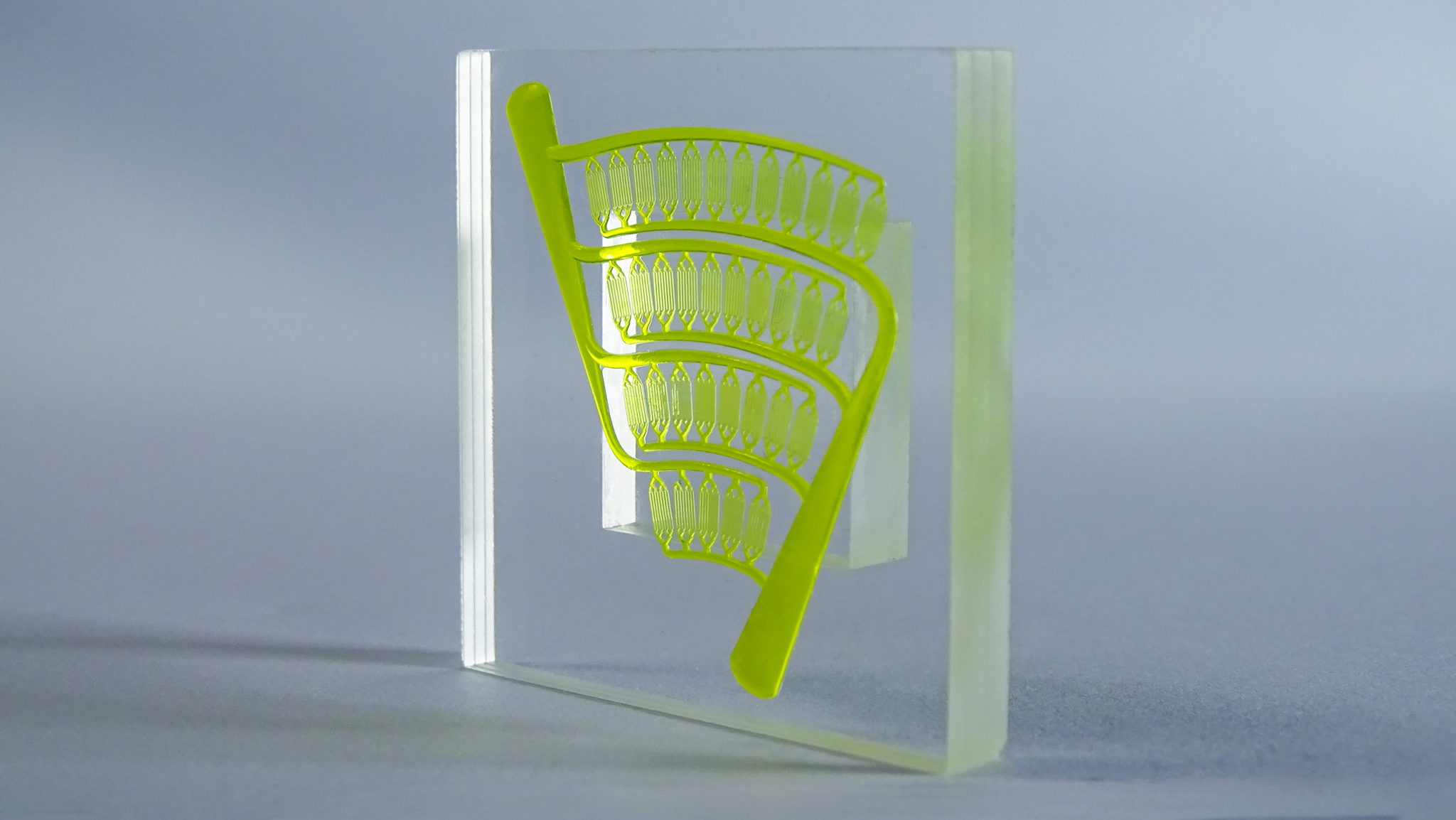

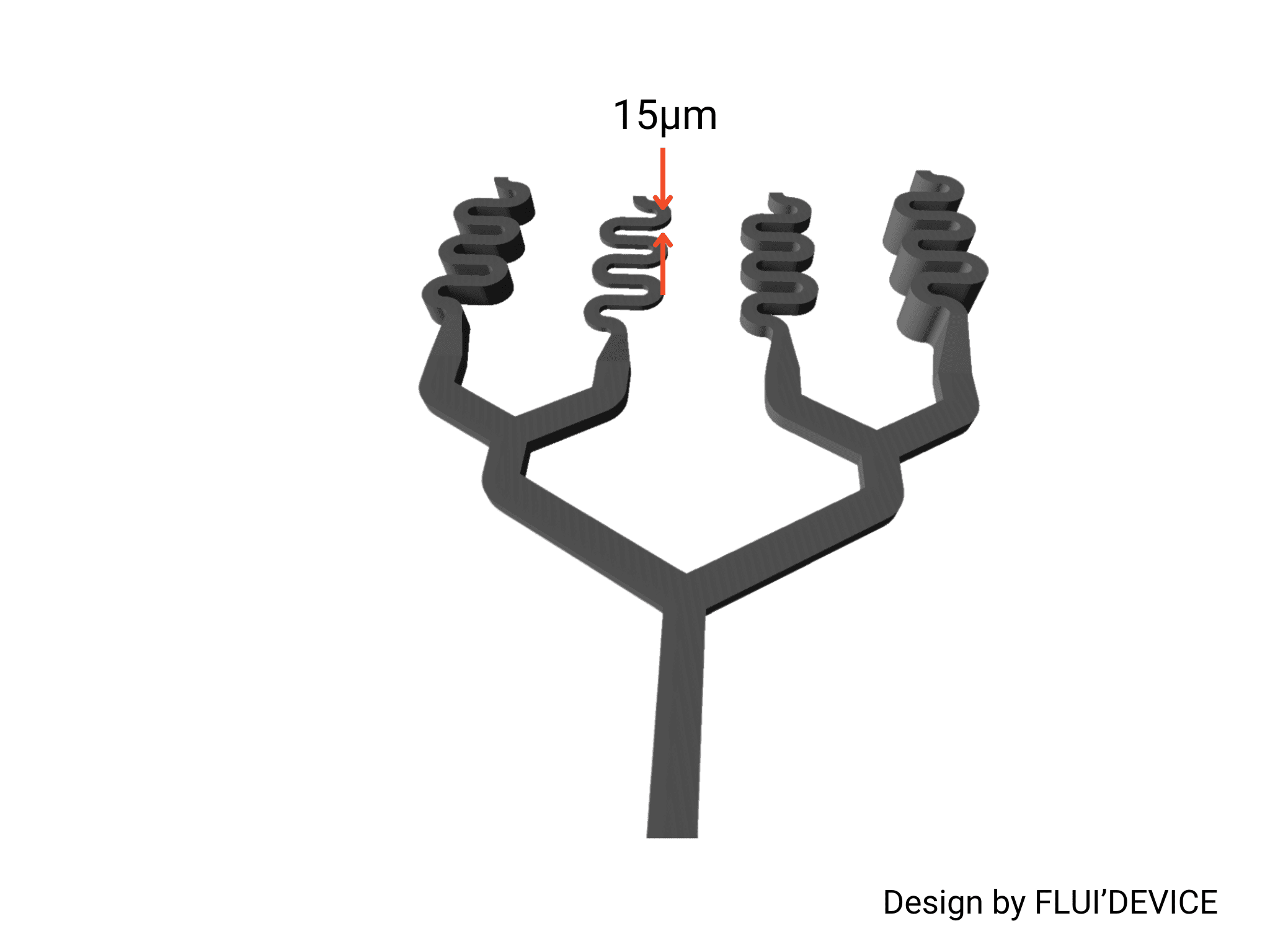

- Micro to millimetric features into one design

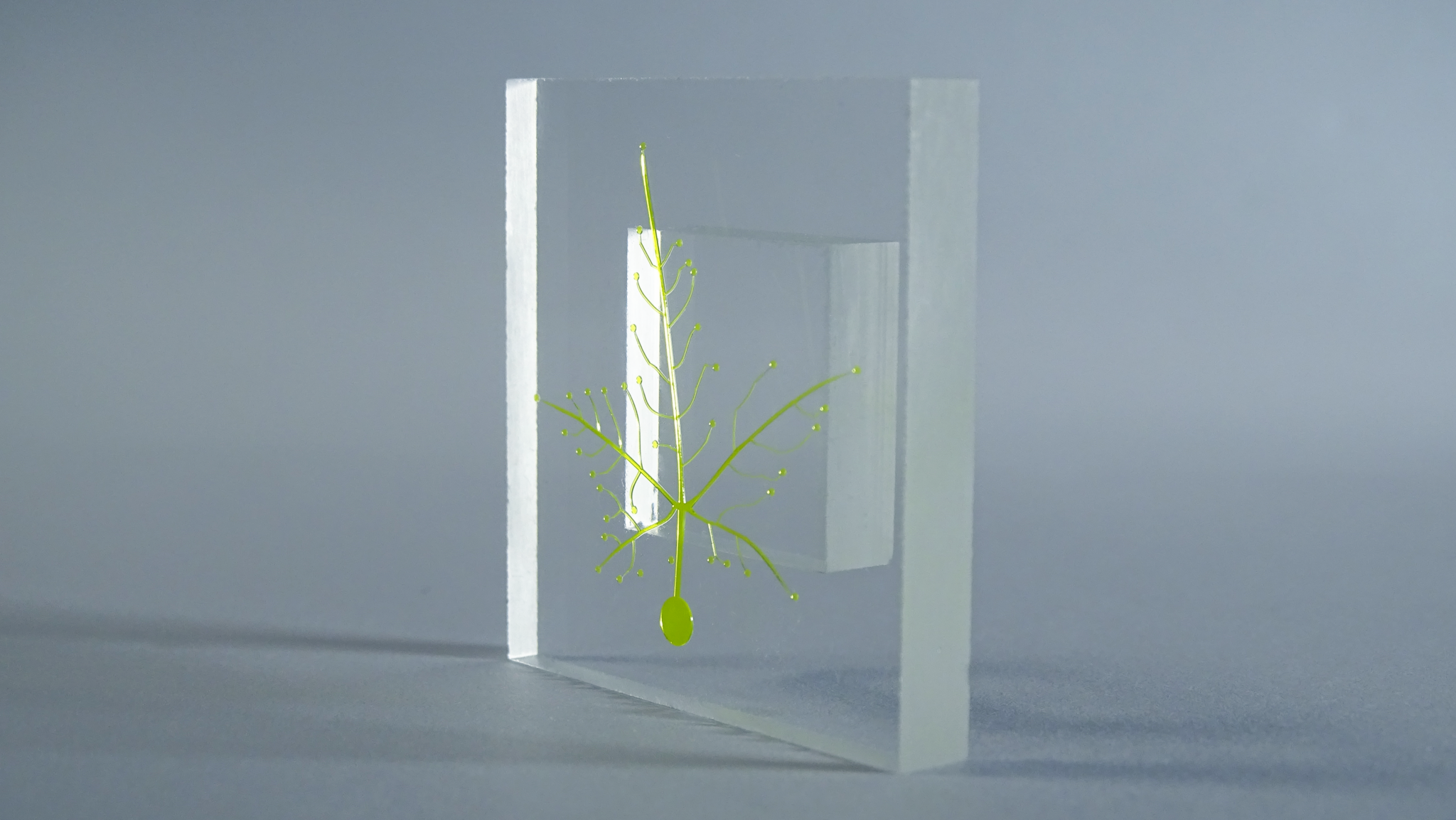

- Enables true cellular microenvironment

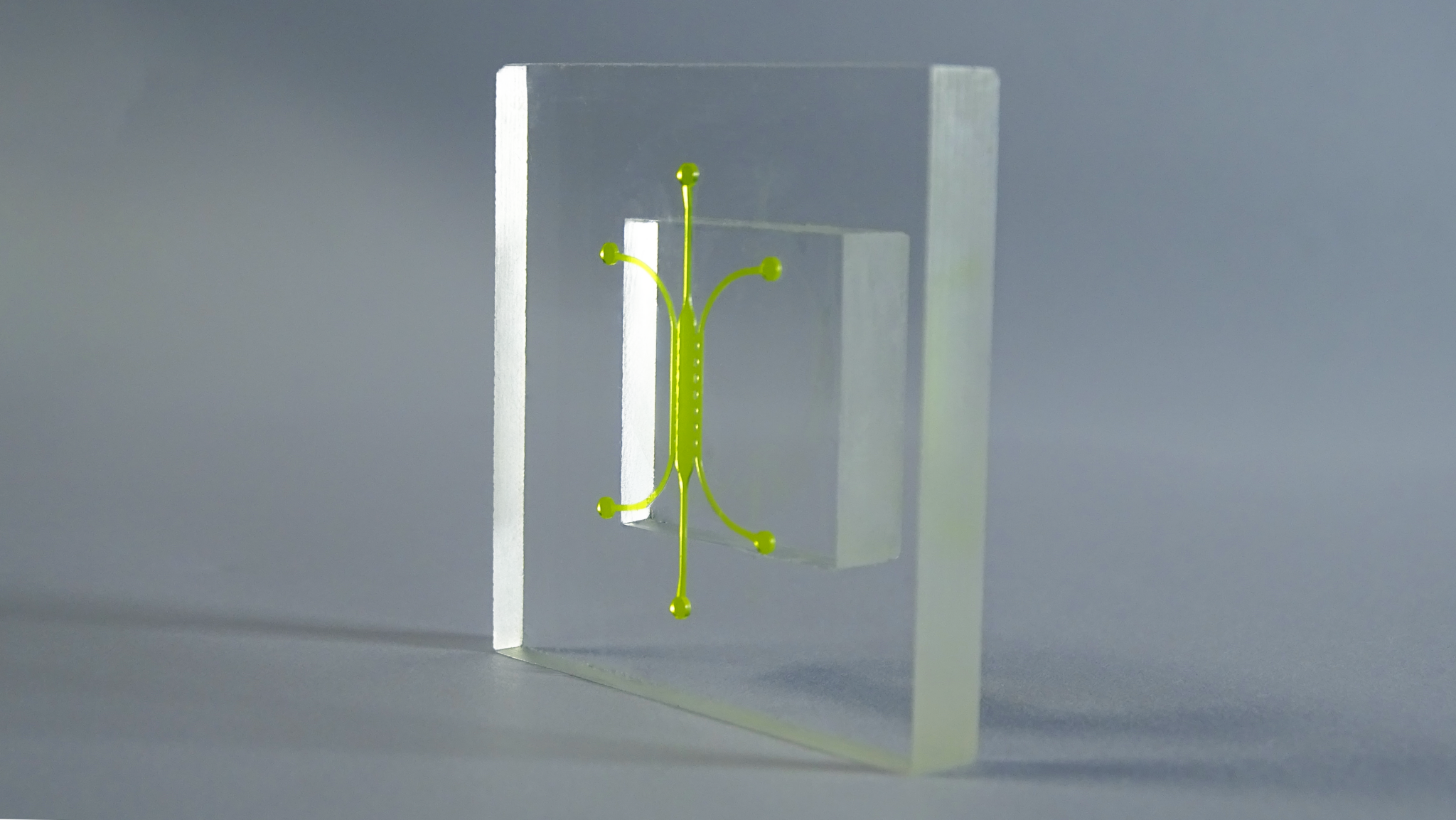

- Advanced design: rounded, slopes, high aspect ratio...

Fast In Every Aspect

- Print straight from your CAD

- Delivery in less than 4 weeks

- Customer support always available

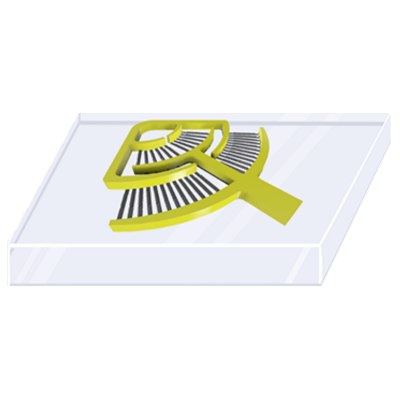

High resolution mold compatible with: Soft Lithography

Let's unpack this:

Print your FLUI'MOLD

Replicate in PDMS

Replicate in Epoxy Resin

Hot Emboss your Flexdym Chip

Our Mold Service Application Fields

- Lab on a Chip

- Organ on a Chip

- Point of Care

- Microneedles

- Photonics

- MEMS

- Microphysiological systems

- Cellular microenvironment

- General microfluidics

The journey of your FLUI'MOLD

.STL File Upload

Validation & Quote

Plots Approval

2PP Laser Print

Fast Delivery

Client Support

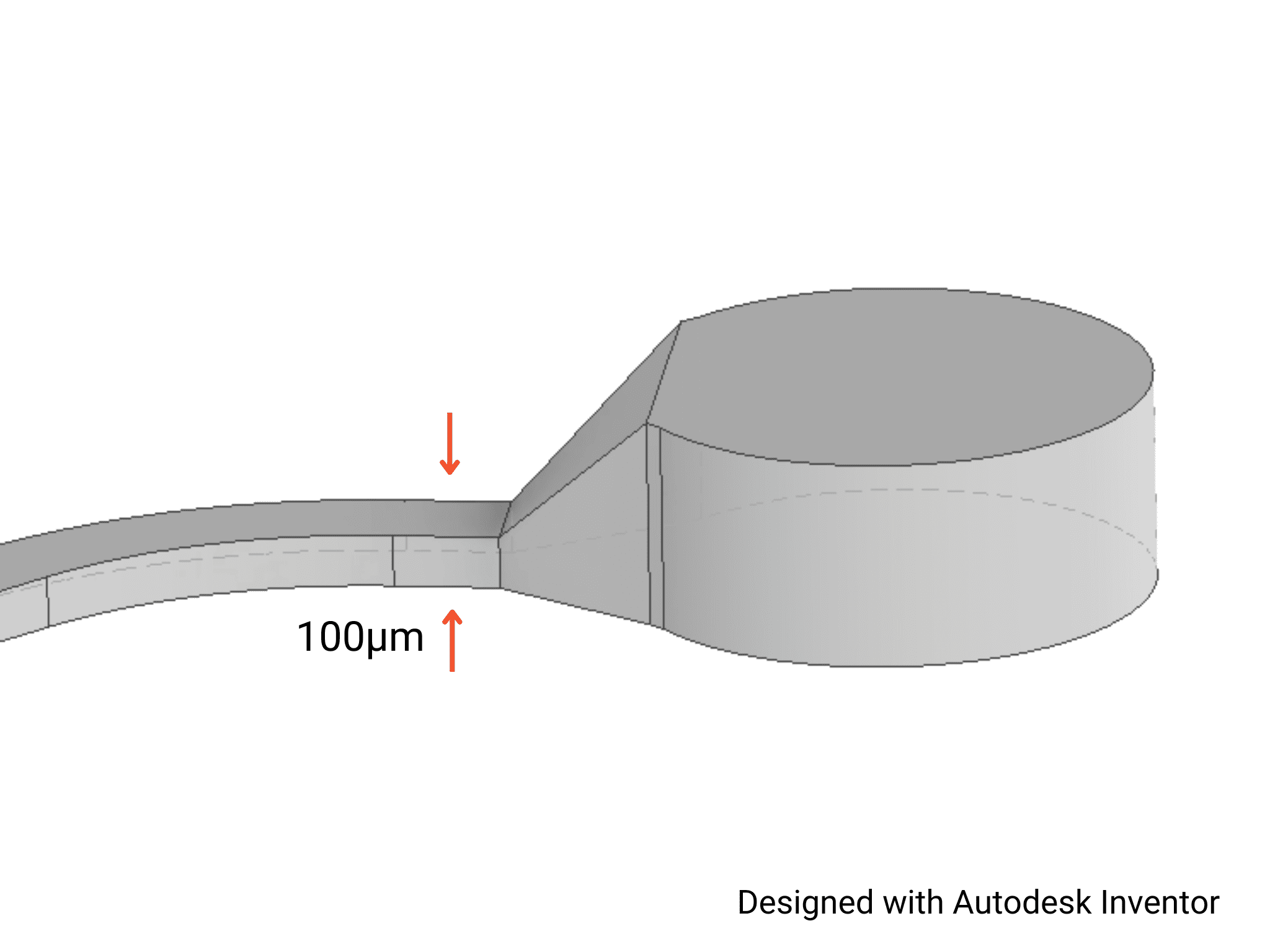

Slopes for fine tuning flow transition and enhanced demolding.

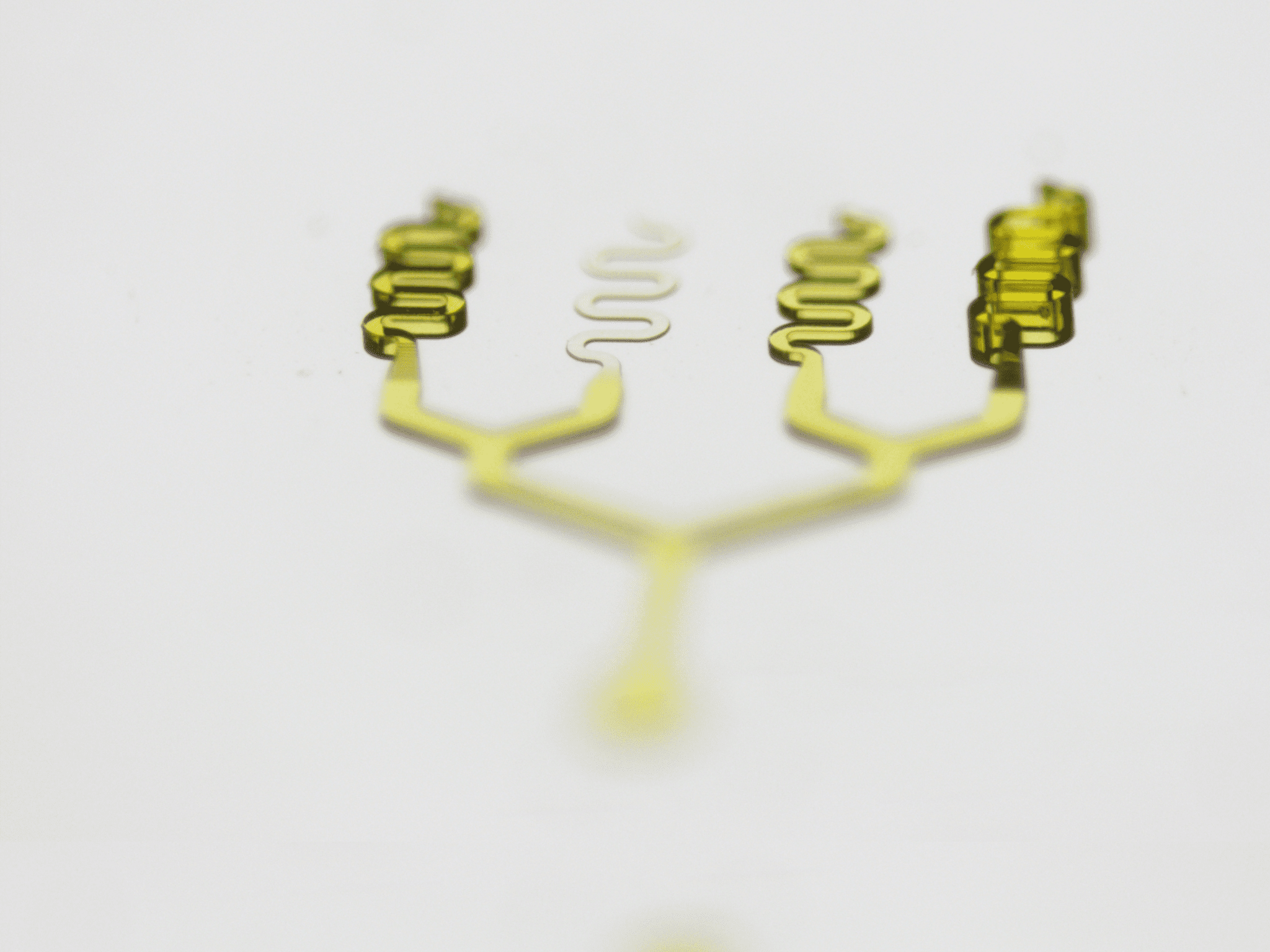

Rounded channels to emulate true cellular micro-environments.

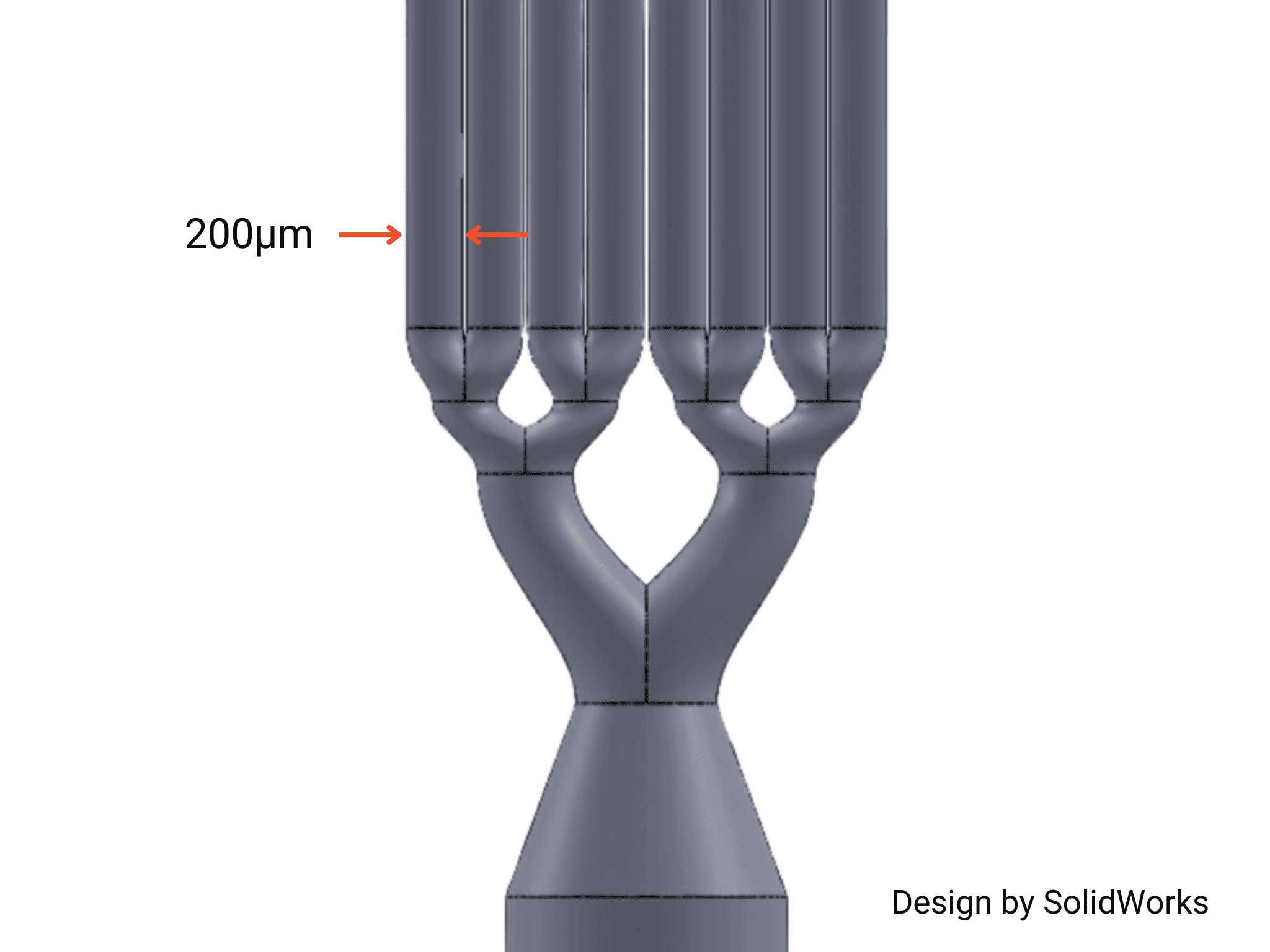

Multiple heights for different mixing ratio, in one single print.

Technical Features

Call us!

From design to microfabrication mold, our experts bring your ideas to life.

They Already Trust our Microfabrication Mold Service

FAQ

Most microfluidic designs are relatively small compared to a SU8 4” wafer. At Eden Tech, we focus on proposing new options, going beyond what photolithography can achieve, by printing very complex geometry for many application fields.

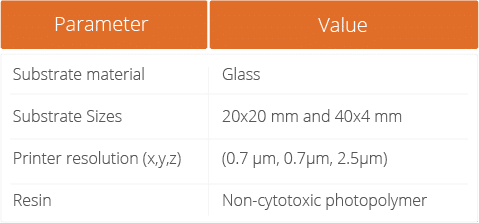

We currently propose a 40X40 and 20X20 mm mold printed with a non-cytotoxic resin on a glass substrate. However, to satisfy every customer needs, we are in the process of developing the 4” wafer mold while maintaining the same high resolution.

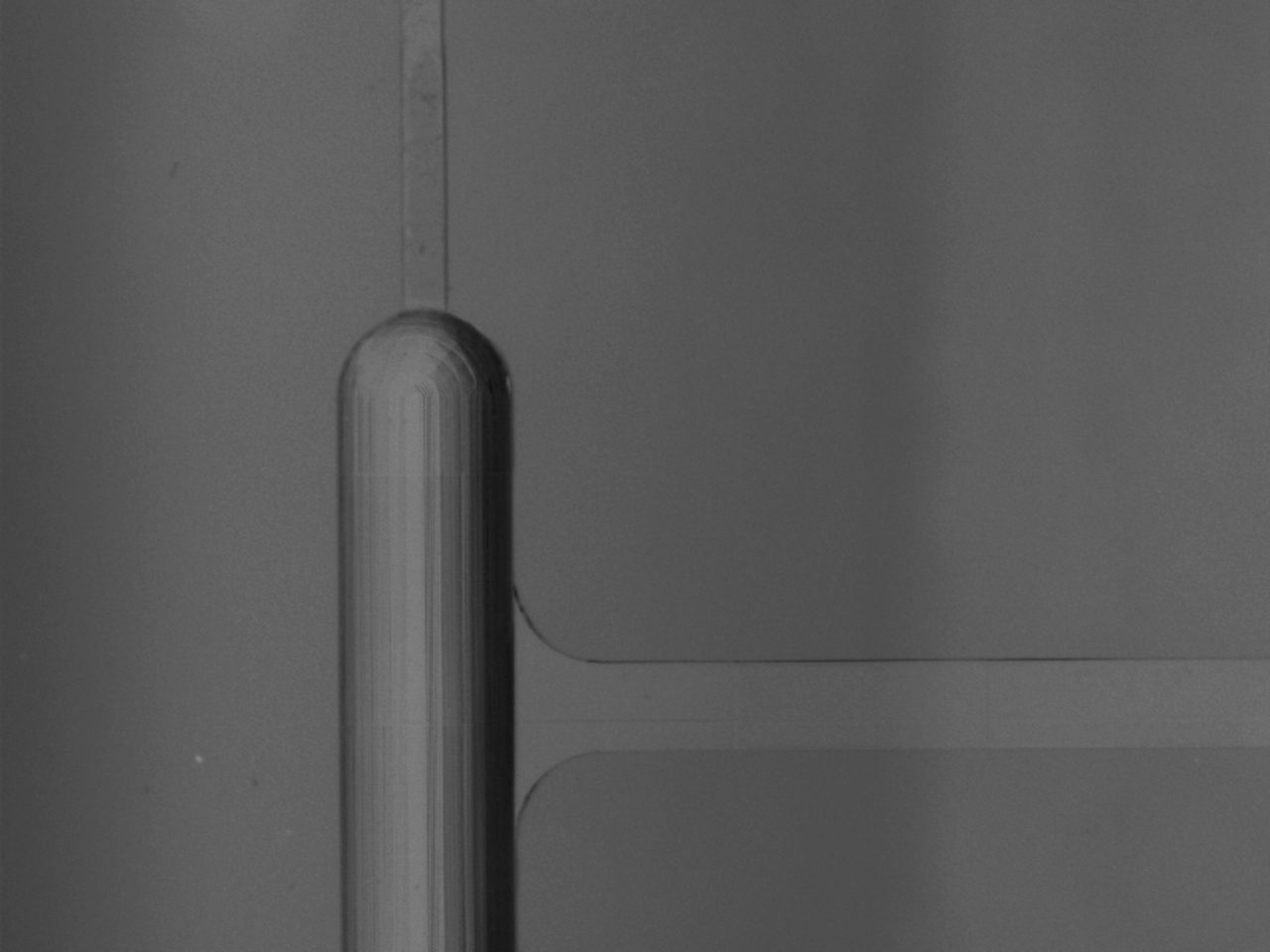

Both FLUI’MOLD and photolithography can achieve high-resolution fabrication (~1µm), but only our service provides seamless variations in microchannel height. With FLUI’MOLD you can refine your research by recreating complex geometries such as circular, sloped, or trapezoidal channels.

This level of precision enables new research opportunities, for instance in rheology where circular microchannels can accurately mimic blood microvessels, or in photonics, by printing µ-semi-circular channels to facilitate the embedding of the optical fibers in microfluidic channels and many more prospects. If you are interested in Contact Our Microfluidic Mold Service.

After mold fabrication, microfluidic devices can be fabricated through one of two main methods: soft lithography and hot embossing. In both cases, devices unmolding can become challenging if the design presents fragile structures, such as a high-aspect ratio.

FLUI’MOLD uses 2PP technology which can print channels with highly precise angle slopes and create trapezoidal microchannels. This allows the integration of bevels in the design to enhance the stability of your mold during the demolding process of PDMS, Flexdym or other polymers.

Yes, we can. We can print structures with A/R of 1/100 and higher, however, to limit the risk of damaging your mold, we recommend maintaining your A/R below 1/5 for soft lithography and 1/3 for hot embossing.

FLUI’MOLD is indeed fully compatible with PDMS soft lithography. We recommend classical mold silanization before its first use. Contact Our Microfluidic Mold Service.

While molds made with FLUI’MOLD cannot withstand the high pressure and temperature required to achieve polymers or Flexdym hot embossing, is possible to generate an epoxy mold starting from FLUI’MOLD.

At Eden Tech, we propose solutions to help you prepare such molds: Epoxym kit or Contact Our Microfluidic Mold Service.