FLEXDYM

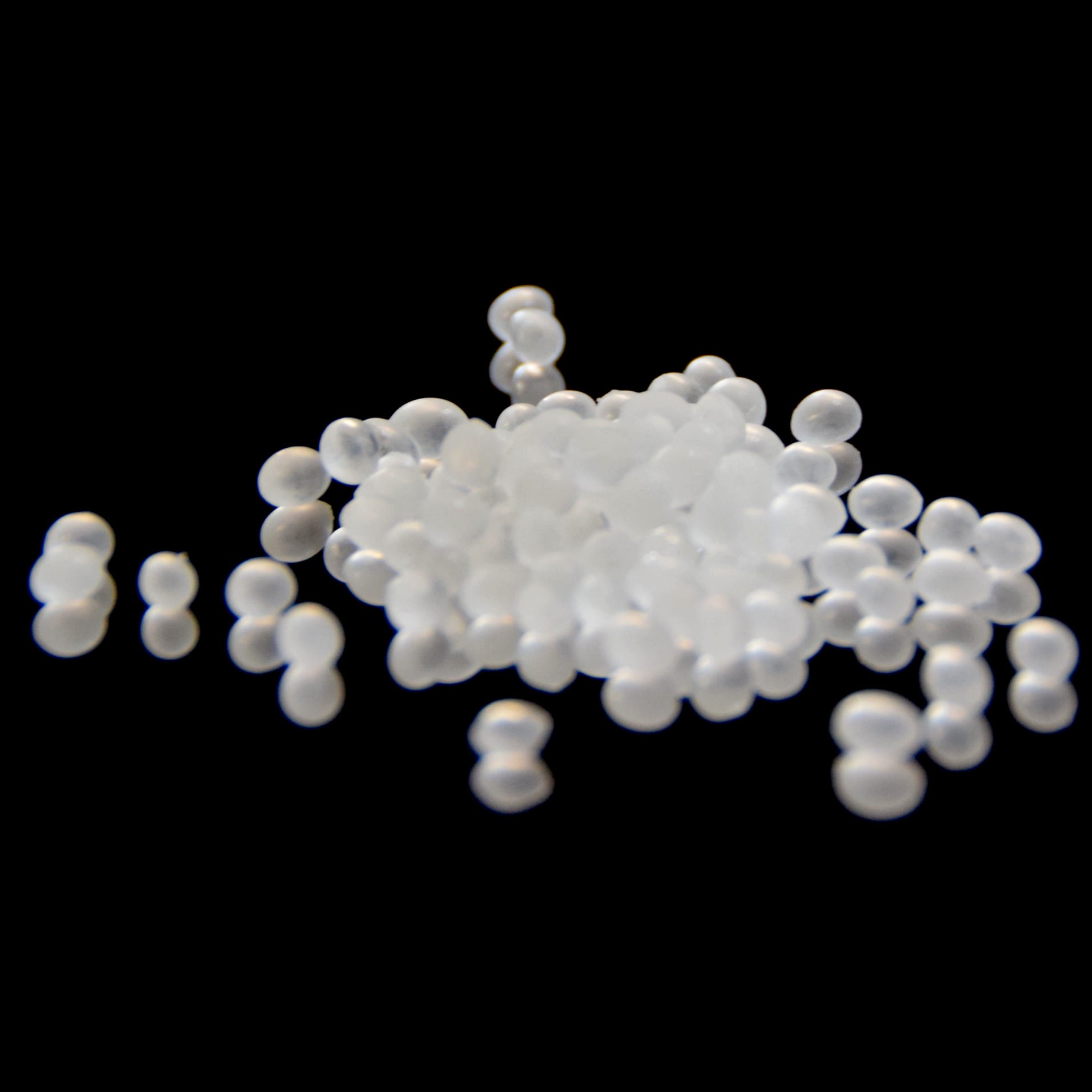

PELLETS

Flexdym Pellets - Polymer For Mass Production

The Flexdym pellets are perfect for the experimented user who has developed a marketable product using this technology and wish to begin mass production or 3D printing.

Flexdym™ Pellets – Device Mass Production

The Flexdym pellets is perfect for experimented user who have developed a marketable product using this technology, and wish to begin mass production or 3D printing. Pellets are sold at different prices from weight ranges: 1-10kg, 11-1,000kg, and 1,001-10,000kg. Please select the variation corresponding to the amount you require.

If you are looking for a solution to microfluidics device mass production, our Flexdym™ pellets may be the perfect material for you.

Microfluidics Scalability Challenges

Microfluidics suffers from a lack of both biocompatible and scalable materials for device mass production. In this domain, academics favor elastomeric materials, such as PDMS (polydimethylsiloxane), for device prototyping. And although PDMS has a relatively simple fabrication protocol, it lacks scalability, and PDMS microfluidic devices must be manually bonded and assembled. This hampers commercialization.

On the other hand, industry experts prefer thermoplastic materials, including COC, COP, PS, or PC. This is due to their scalability and compatibility with mass production processes, e.g. injection molding. However, these materials also harbor drawbacks for biomedical applications. For example, they require bonding treatments with harsh chemical and temperature conditions, that are not ideal for surface functionalization. Additionally, they are expensive to use at prototyping stages – limiting their widespread use.

The Flexdym™ Solution

To solve this issue, we have created Flexdym™. Flexdym™ is a popular alternative to PDMS and specifically created for the scale up of microfluidic biomedical devices, thanks to its compatibility with injection molding and 3D printing. Moreover, Flexdym is ideal for biological applications, because it is certified biocompatible ISO 10993 (parts 4, 5, 6, 10, 11) and UPS Class VI. This demonstrates Flexdym™’s low toxicity and its ability to be used for medical applications. Other advantages of Flexdym™ include optical transparency and low molecular sorption, which make Flexdym™ a top choice for cell culture and diagnostic applications.

Now you can finally use the same material at all scales, from prototyping to mass production of your chips. Flexdym makes commercialization of microfluidic chips easy.

Interested in first testing out the Flexdym™ polymer? Check out our Flexdym™ Starter Pack. But if you already have experience with Flexdym™ but require more development before beginning mass production, you should see our Flexdym™ Rolls.

And make sure to follow us on LinkedIn and Youtube to get our the lastest Flexdym™ news!

| Weight | N/A |

|---|---|

| Quantity | 1-10kg, 11-1000kg, 1001-10000kg |