Epoxym Kit : 2-Step Protocol

SU-8 & Silicon Wafer

Pattern is created using SU-8 and standard photolithography techniques.

PDMS Intermediate

PDMS is cast on the silicon SU-8 mastermold & baked.

Final Epoxy Resin mold

Epoxym resin is poured on PDMS mold. Final Epoxym replica mold baked & ready.

01

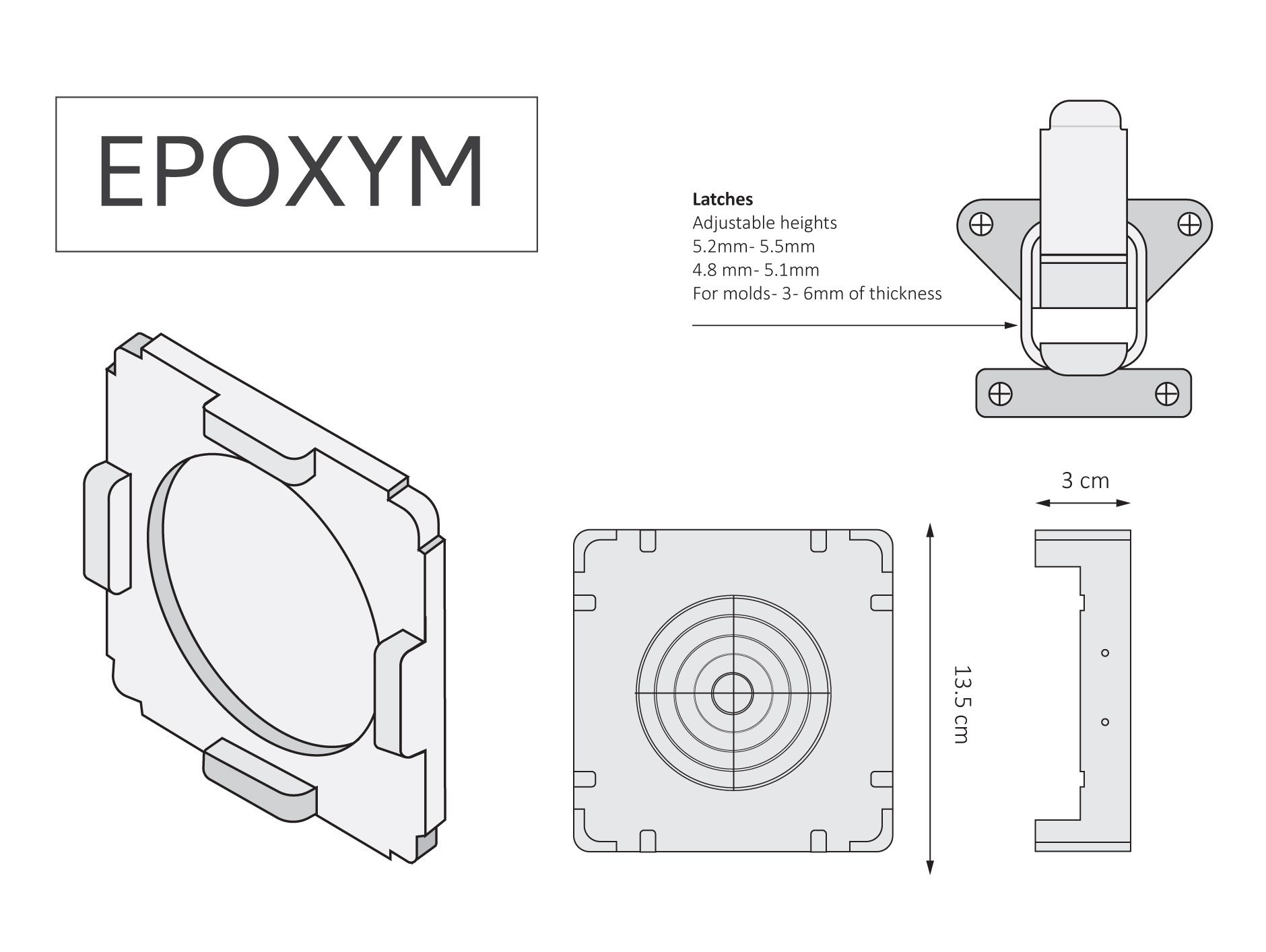

EPOXYM FRAME

Epoxym Kit Component

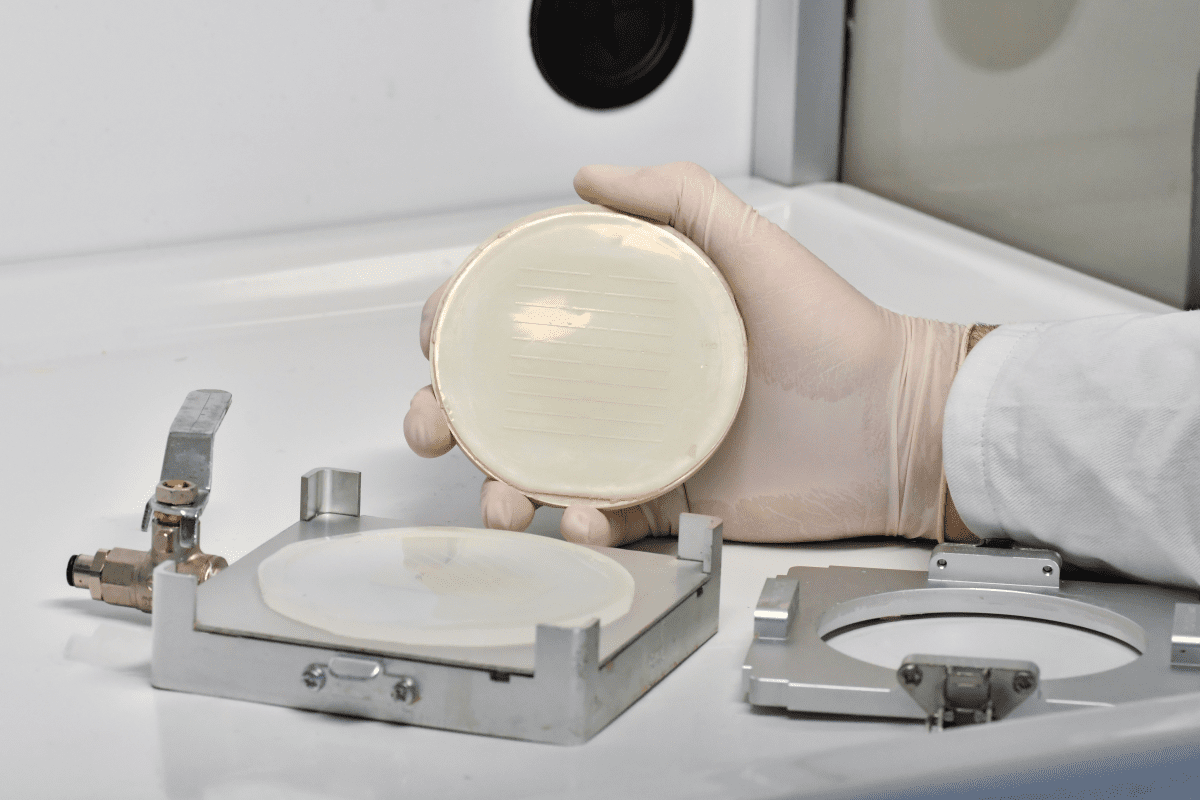

The mold frame is composed of two parts: the base/bottom of the frame and the lid of the frame. The base contains a small hole in its center, allowing for a vacuum seal to be created during the molding process. The vacuum can be controlled using a vacuum valve. The lid contains a large circular opening at its center, to enable the casting of the mold. The entire system has an adaptor connecting the frame to the vacuum pump tubing.

02

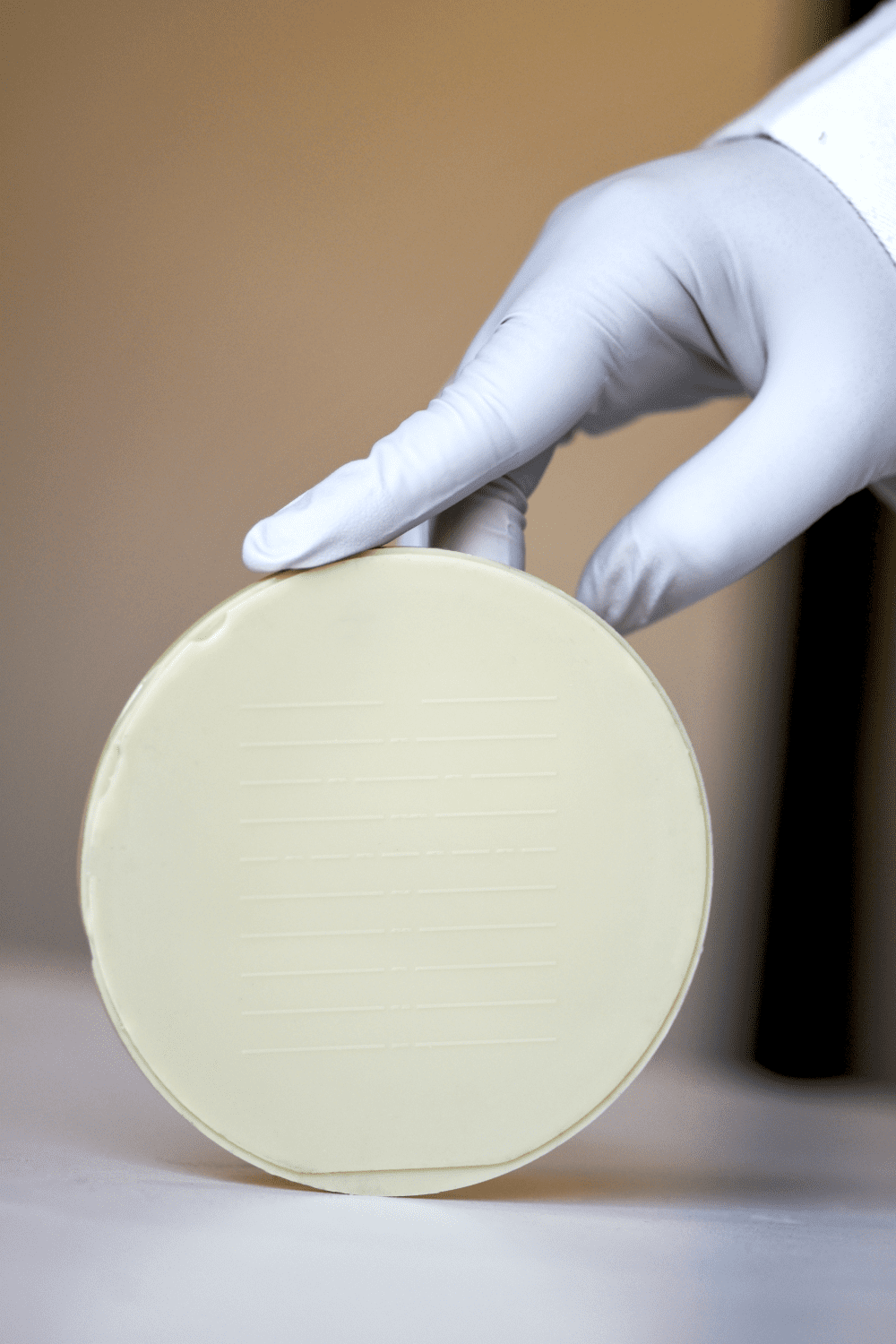

EPOXY RESIN

Epoxym Kit Component

Create a monolithic & robust mold using our carefully selected epoxy resin. It has high replication fidelity (0.2 μm) and high-temperature resistance (180°C).

ADVANTAGES OF EPOXY MOLD

- High temperature resistance.

- Withstands high number of molding cycles

- More robust than silicon wafers

- Saves time and money

EPOXYM KIT

LATCH MECHANISM

Brochure Request