EPOXYM

MOLD REPLICATION UNIT

Epoxym

Produce robust epoxy molds replicas that offer a superior experience to classic SU-8 & silicon masters. Now you can increase the molding throughput of all your devices, while increasing the life-span of you silica wafers.

Epoxym Kit – Microfluidics Mold Solution

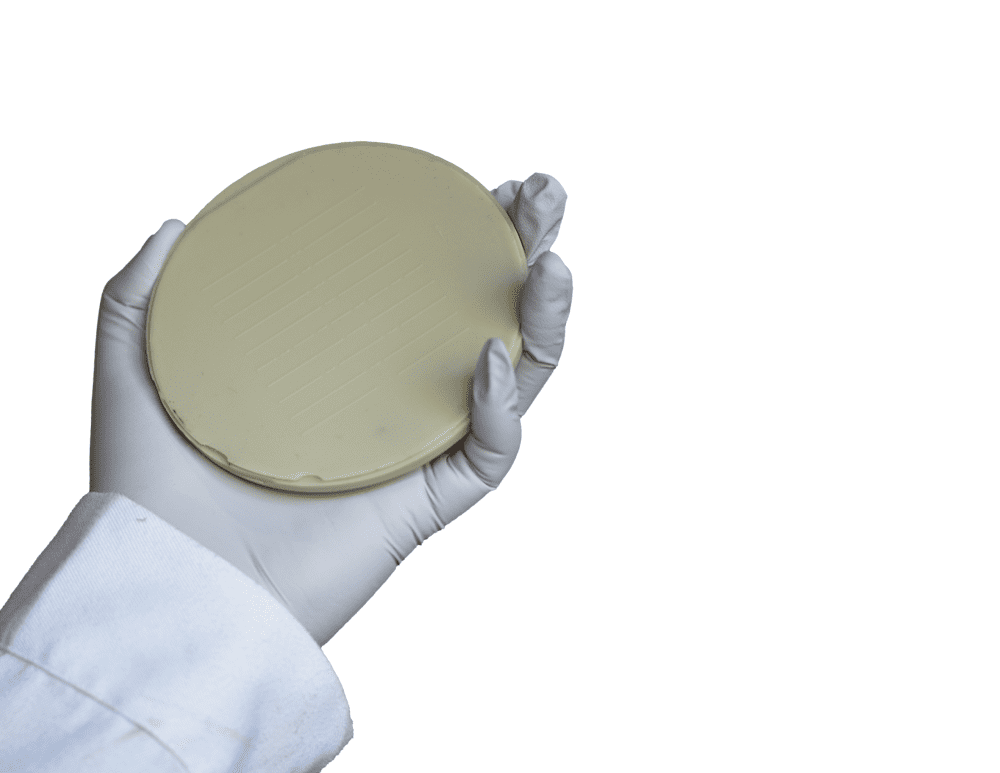

Are you searching for an alternative microfluidics mold solution to your fragile silicon wafers?

In microfabrication techniques such as hot embossing, it is imperative to have a robust mold to withstand the mechnical stress applied during molding and unmolding. That’s why we created the EpoxymTM kit.

What Does the Epoxym Kit Do?

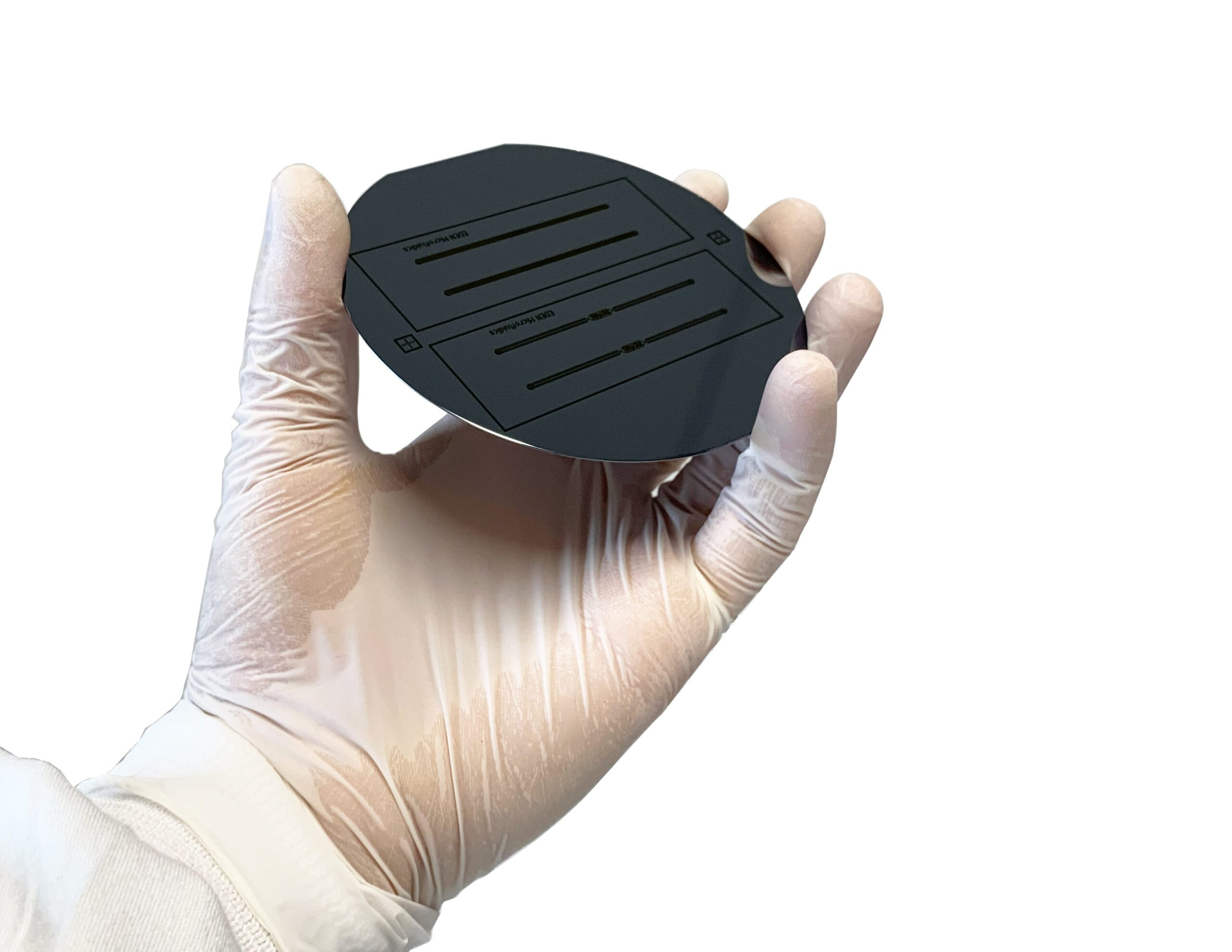

It is a multifunctional and easy-to-use microfluidics mold solution system that replicates fragile silicon molds into robust epoxy resin molds. Once the silicon wafer is replicated, then it can be safely tucked away and excluded from your routine fabrication. This preserves your fragile and valuable master mold manufactured by microfabrication techniques (e.g. SU8 photolithography, DRIE etching, etc).

The high temperature resistant epoxy molds are robust and less likely to break during microfabrication methods such as hot embossing. This can consequently save you time and money, especially if you do not have direct access to mold fabrication equipment or have a limited budget.

How Does It Work?

The Epoxym kit creates replicate molds through a two-step casting system:

1. First fabricate a negative mold in PDMS

2. Next, use the PDMS intermmediate to fabricate the final replica epoxy mold suitable for hot embossing (see our Sublym™ machine for molding within minutes).

The Epoxym it includes a frame system designed for the replication of 4-inch master mold wafers. The frame is adjustable to different heights, using screws and a latch mechanism. It is also accompanied by a valve and tubing, which permits the entire system to be connected to a vaccum pump (not included in the kit).

Therefore, the Epoxym microfluidics mold solution creates ideal molds for molding FlexdymTM and other materials through hot embossing. To find out more about these solutions please refer to our Epoxym brochure and Epoxym user guide.

Remember you can follow Eden Tech on Linkedin and Youtube to get all our current news!

| Dimension | 16 x 23 x 6.5 cm3 |

|---|---|

| Vacuum inlet | 6mm rigid tubing |

| Wetted Materials | AI and FKM |

| Weight | 1.35 Kg |

| Max Master Size Config. A | Up to 4" in diam. |

| Max Master Thick. Config. A | 8 mm |

| Operating Temp. Config. A | 0°C to 90°C |

| Countermold Thick Config. B | 3 to 7 mm |

| Operating Temp. Config. B | 0°C to 140°C |