ACCESSORIES

Fast and Easy Integration

Essential Microfluidics Accessories

The necessary connectors and puncher for a complete microfluidic experimental setup.

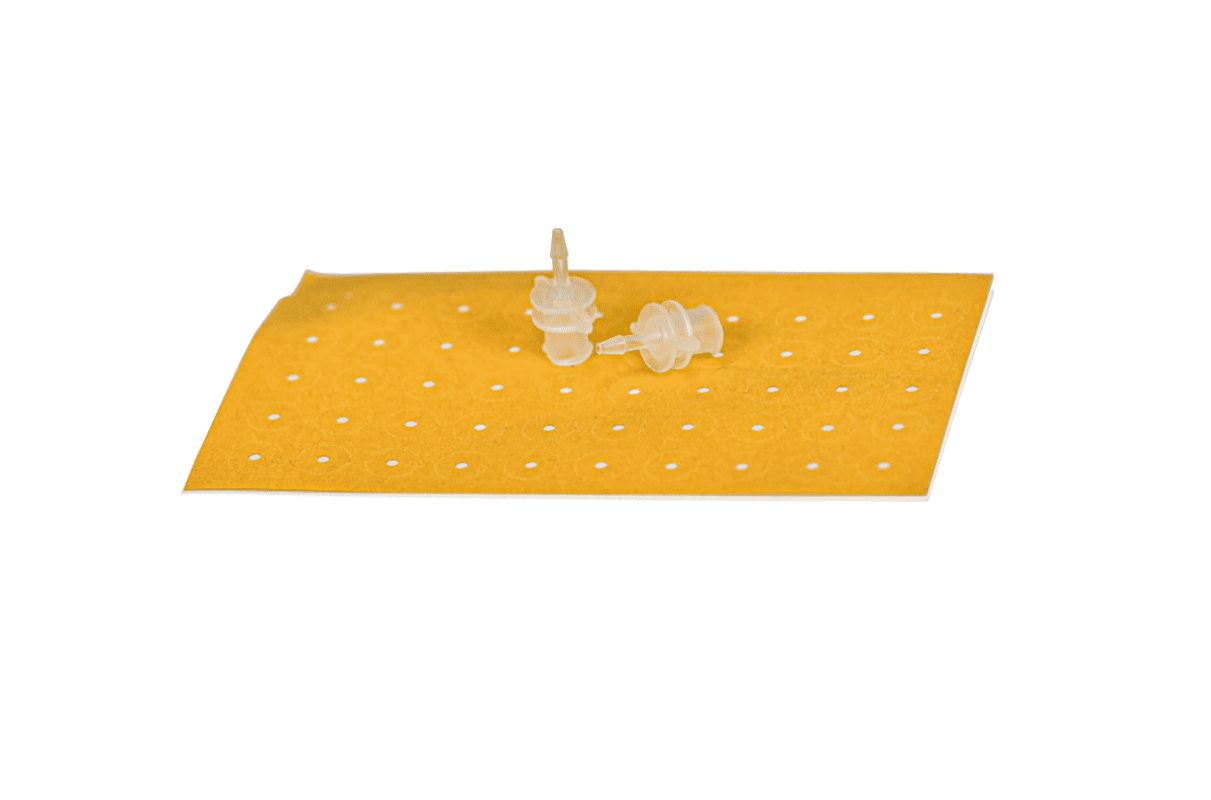

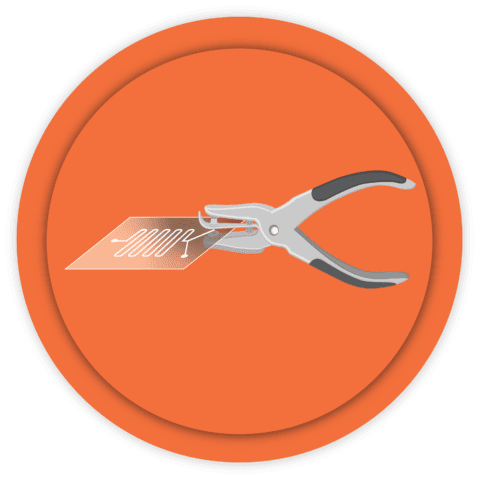

Hole Puncher

Easily create microfluidic inlets with Eden Tech’s hole puncher, available in 0.5 mm, 1.5 mm, 2 mm, and 4 mm sizes.

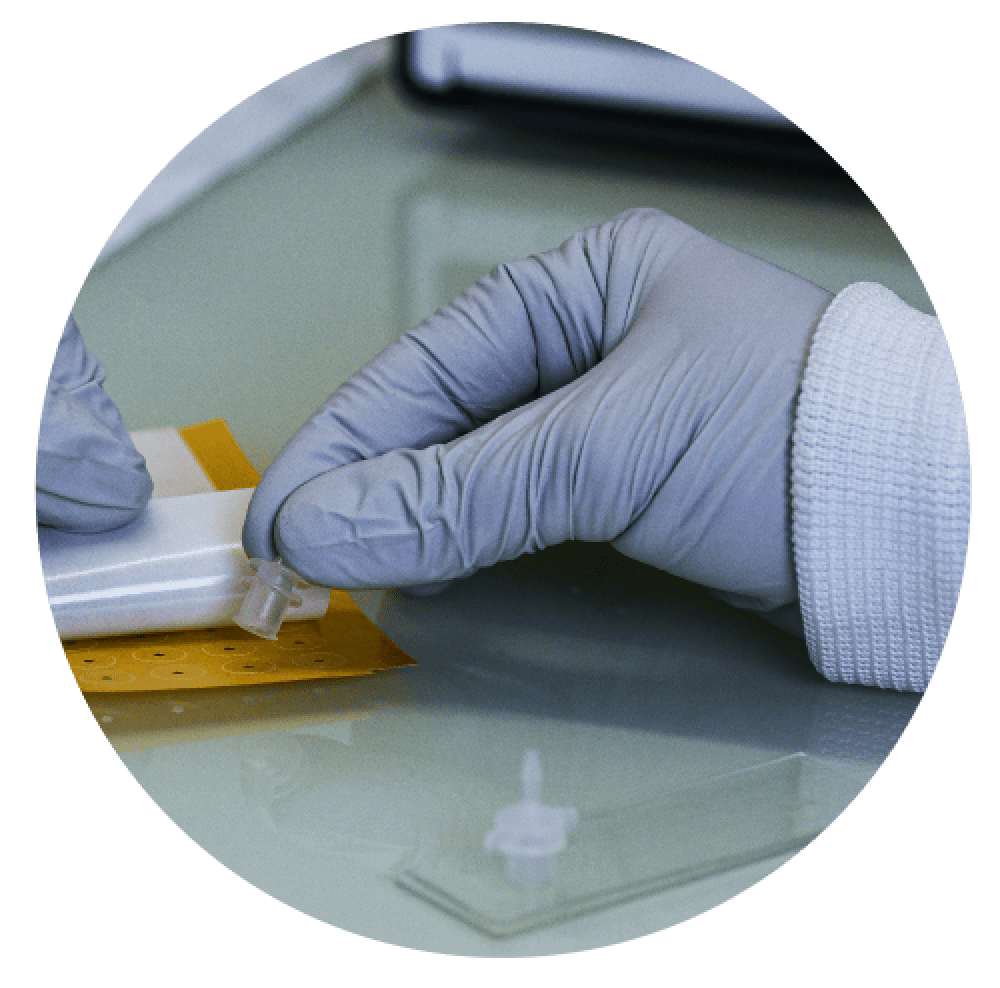

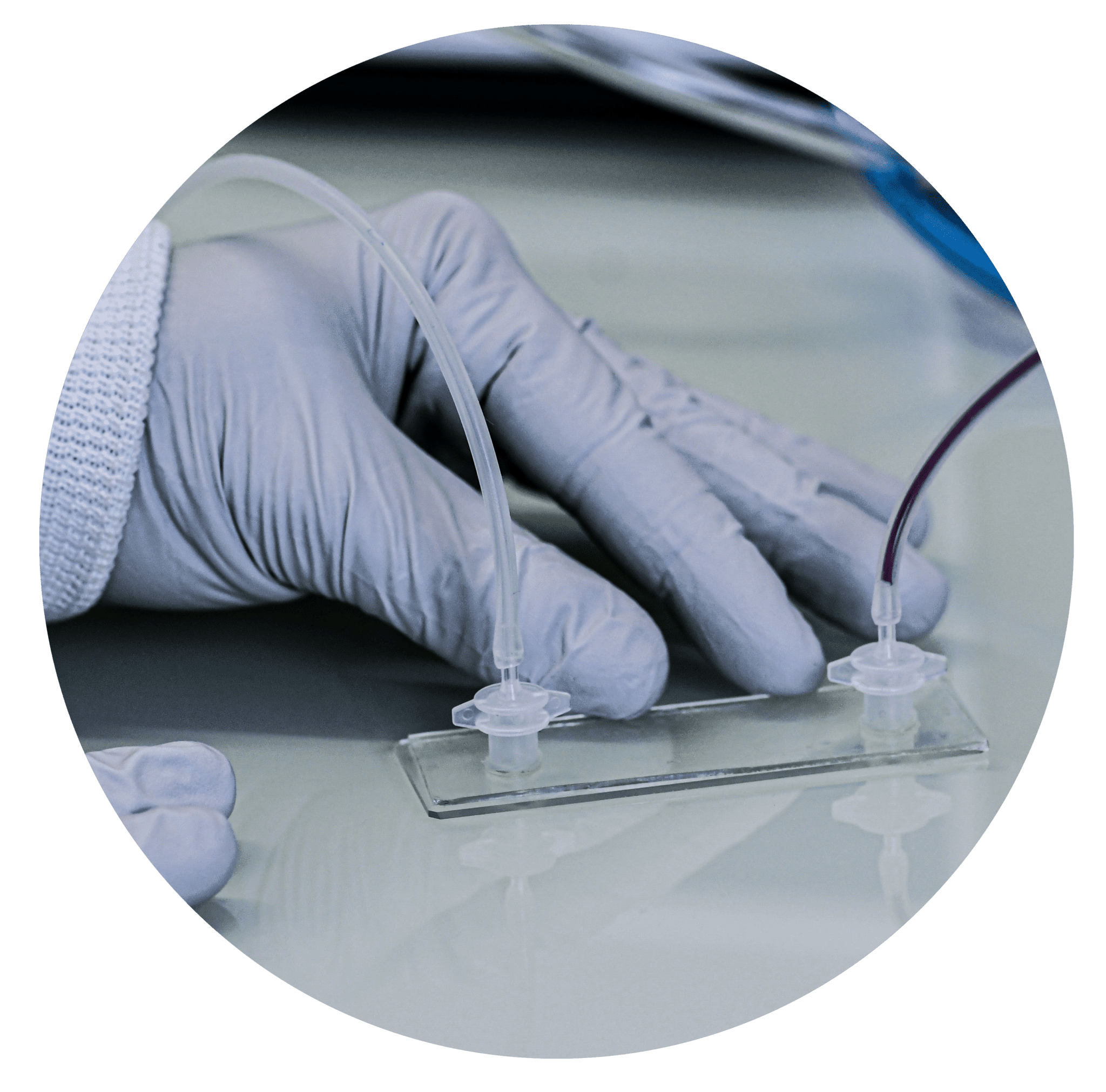

Connector Kits

Our Flexdym devices connect to pumps using luer or compact olive connectors, both supplied with cytotoxicity-tested O-ring stickers. The olive connectors offer reduced dead volume for better performance.

01

DIE

Forged steel die cuts allow rapid ad easy creation of inlet and outlet ports in different materials used for microfluidic chip fabrication. They can be used with thermoset PDMS, our thermoplastic elastomer Flexdym, or other soft elastomeric materials.

02

PUNCHER

Select the die cut size of your choice and screw onto puncher. Each puncher comes with one die cut, but additional die cut are sold separately. The puncher functions just as a the traditionally used biopsy punchers, but with longer wear.

03

APPLICATION

This product is our recommended method for creating inlet and outlet ports for chip-to-world connection of Flexdym microfluidic chips.

01

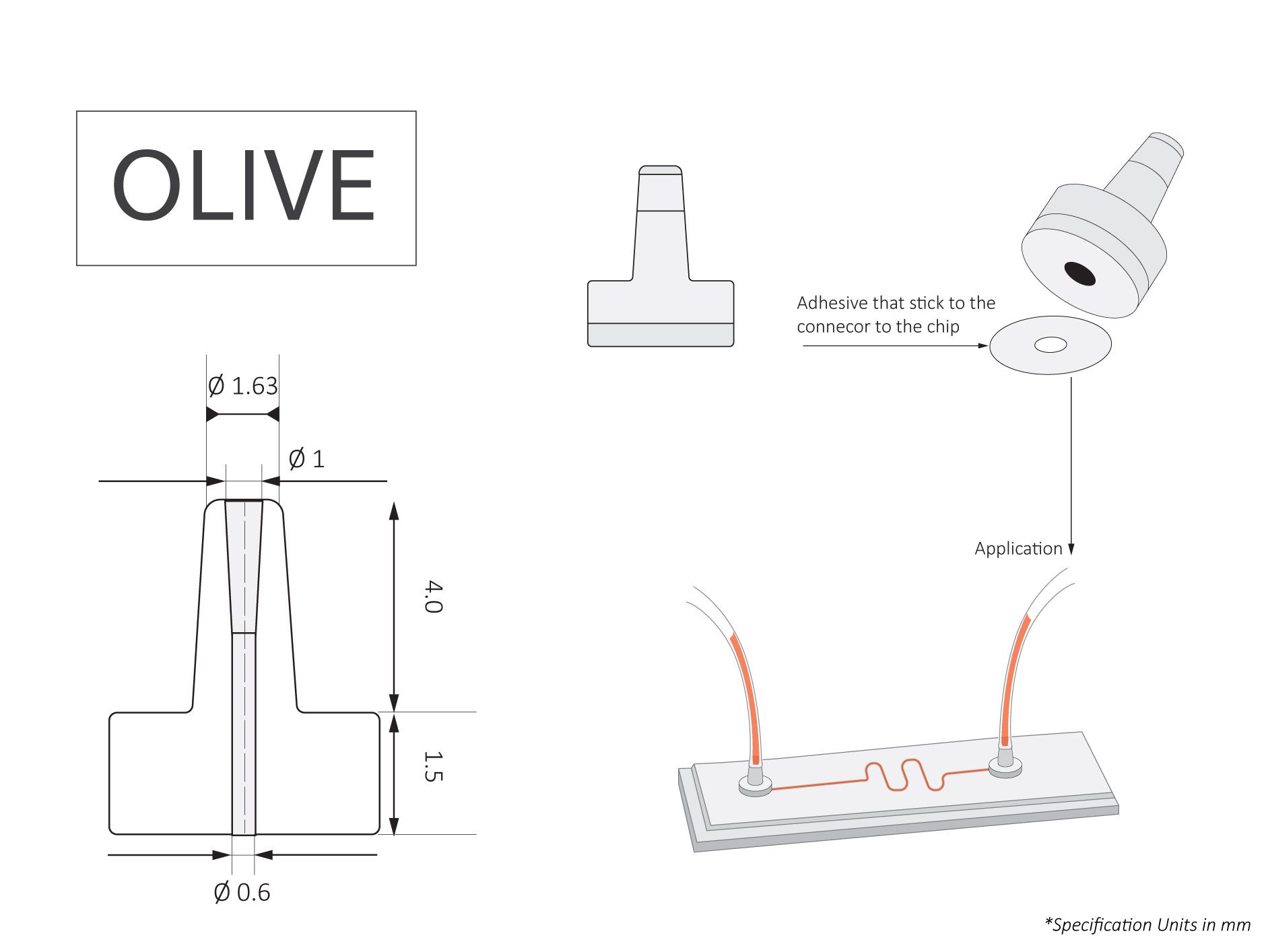

OLIVE

CONNECTORS

Olive connectors provide an easy chip-to-world interface from microfluidic chips, including those fabricated from Flexdym thermoplastic elastomer. The olive connector is fixed onto the chip surface via an O-ring adhesive tested for cytotoxicity. The connector has a small internal diameter of O.4 mm which reduces dead volume of reagent at the device inlet.

02

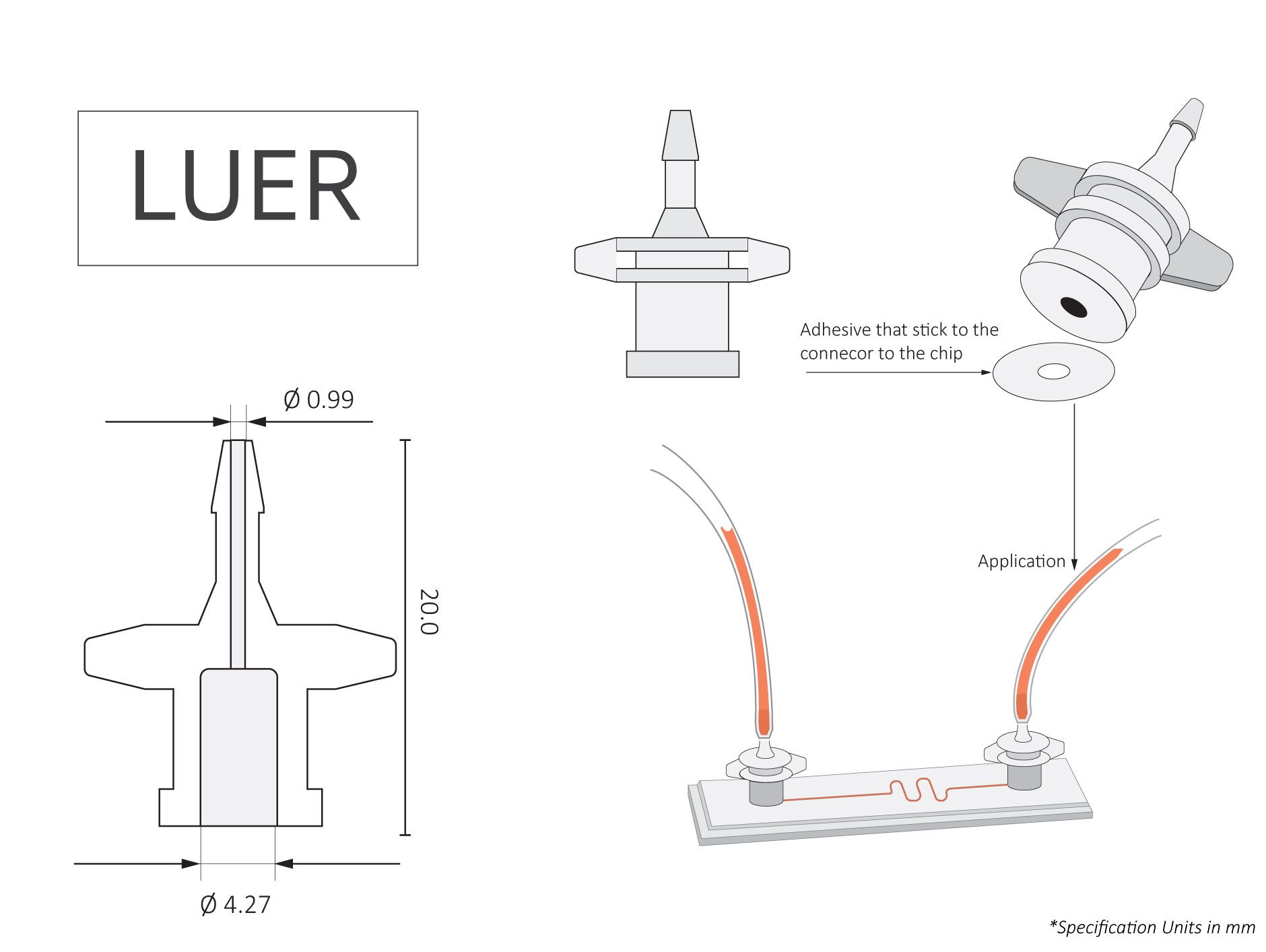

LUER

CONNECTORS

The Luer connectors are made from medical grade PP and can also be used for chip-to-world connection of Flexdym microfluidic chips. They are fixed onto the chip surface via O-ring adhesives tested for cytotoxicity. The Luer connectors have an internal diameter at the base of 4.27 mm.

Stick adhesive to adaptor

Align & stick adaptor on the inlet

Now run your setup!

Step-By-Step: Flexdym Devices

01

Cut a Flexdym sheet

02

Mold within 2 minutes

03

Create inlet/outlet ports

04