Microfluidic Cell Culture: Alternative to PDMS and Microfluidic Design

Introduction

Microfluidic cell culture has emerged as a powerful tool in the biomedical and pharmaceutical fields. By integrating cell culture into microfluidic devices, researchers can better mimic physiological conditions, control environmental factors, and conduct high-throughput screenings in a much more efficient and reproducible manner. This blog article explores this growing field, the advantages of using Flexdym in these applications, and how FLUI’DEVICE simplifies the design process for researchers and engineers alike.

What is Microfluidic Cell Culture?

Microfluidic cell culture refers to the practice of cultivating cells within tiny fluidic environments, typically at the micron scale. These systems replicate the conditions of human tissues, enabling more accurate modeling of biological processes. Unlike traditional cell culture methods, microfluidic platforms offer precise control over parameters such as flow rates, nutrient delivery, and waste removal, creating an ideal environment for cell growth and interaction.

The use of microfluidics in cell culture allows for high-precision experiments with reduced reagent consumption, better cell viability, and the ability to observe cellular behavior in real time. This level of control is especially important for applications such as drug screening, cancer research, and tissue engineering.

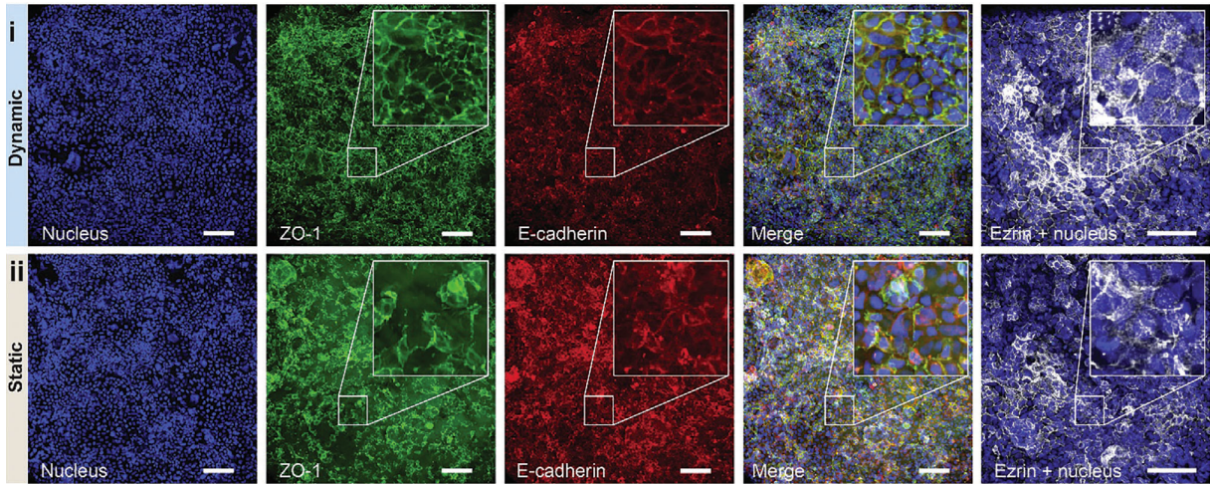

A Versatile Intestine-on-Chip System for Deciphering the Immunopathogenesis of Inflammatory Bowel Disease – Nguyen et al

Key Benefits of Microfluidic Cell Culture:

- Improved Control Over Environment: Microfluidic systems allow for fine-tuned control over the microenvironment, including temperature, pH, oxygen levels, and nutrient gradients.

- Reduced Sample Volume: The tiny scale of these devices drastically reduces the amount of reagents and cells required, making experiments more cost-effective and sustainable.

- High-Throughput Screening: Microfluidics facilitates parallelized experiments, allowing for high-throughput screening in drug discovery, toxicity testing, and disease modeling.

- Better Replication of In-Vivo Conditions: These devices can more accurately replicate the shear stress, nutrient gradients, and interstitial flow found in human tissues.

Materials for Microfluidic Cell Culture Devices: When designing microfluidic systems for cell culture, choosing the right material is critical. The material should be biocompatible, transparent for optical observation, and able to handle the specific shear forces associated with cell culturing.

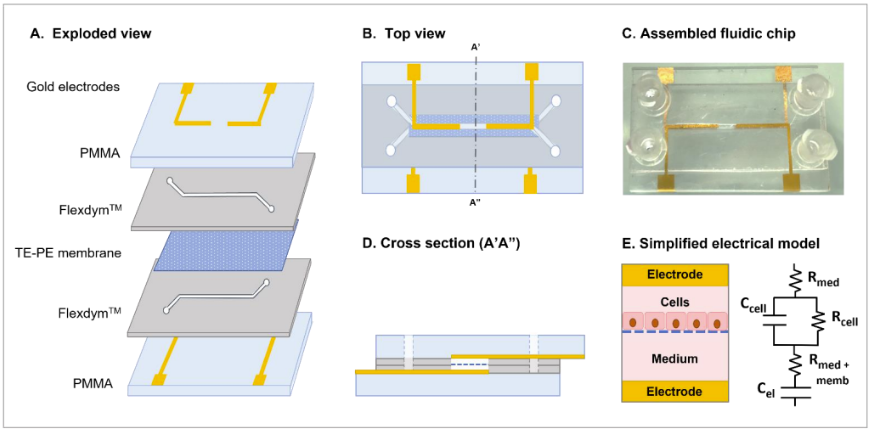

Figure 1: Multilayer chip design with integrated membrane and electrodes.

A) Exploded view showing the materials of the microfluidic device: clear PMMA with 3D printed gold electrodes, Flexdym, and polyester track-etched membrane

B) Top view of the chip

C) Cross-section showing the apical and basal microchannels. The microchannels are 2 cm long, 1 mm wide, 250 µm high

D) Photograph of the assembled organ chip (with connectors)

E) Simplified electrical model.

Microfluidic platform integrating Caco-2 spheroids-on-chip for real-time investigation of intestinal epithelial interaction with bacterial extracellular vesicles, Silvia Tea Calzuola et al

Flexdym, a high-quality material with exceptional properties, has become the material of choice for many microfluidic applications, including cell culture. Here’s why:

- Flexibility: Flexdym is flexible enough to accommodate the physical strains that occur in dynamic environments, making it perfect for devices where there is continuous fluid flow and mechanical stress.

- Biocompatibility: The material is chemically inert and non-toxic to cells, ensuring a safe environment for cellular growth and experimentation.

- Transparency: Flexdym offers excellent optical clarity, allowing for precise imaging and observation of cell behavior within the microfluidic channels. Flexdym does not have autofluorescence.

Customizability: Flexdym can be easily processed and tailored to meet specific needs in cell culture devices, from channel design to surface treatments, allowing researchers to customize their designs.

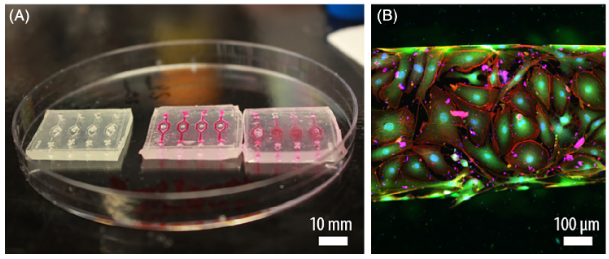

Flexdym Cell Culture Device (Salmon et al.,2020)

(A) The open and empty microchip made with Flexdym, filled with rhodamine B and then closed for perfusion assay. (B) Cell monolayer of primary mouse endothelial cells in confocal microscopy, stained with DAPI for nucleus (blue), GFP for cytoskeleton (green) and Phalloidin for Actin fibers (red).

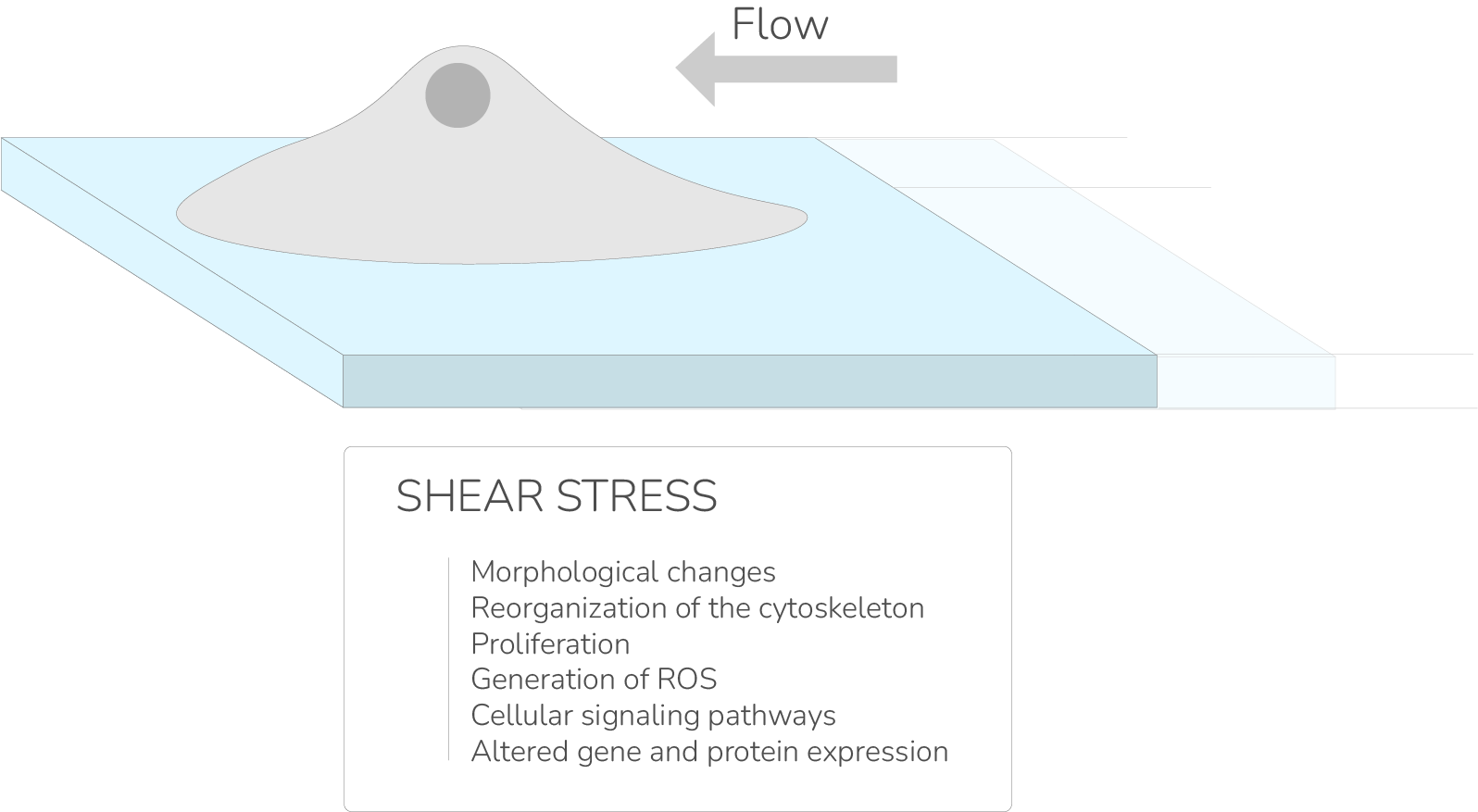

The Influence of Shear Stress on Cell Culture in Microfluidic Devices

One of the most important factors in cell culture is shear stress. Shear stress is the force exerted by the fluid flowing through the microchannels on the cells. This force affects cell morphology, behavior, and gene expression, which is why it must be carefully controlled in microfluidic designs.

- Low Shear Stress: In certain applications, such as stem cell culture, low shear stress is required to maintain cell viability and undifferentiated states.

- High Shear Stress: In other applications, such as endothelial cell studies, high shear stress can be used to mimic blood flow conditions, which can trigger specific cellular responses related to vascular diseases.

Designing the right fluidic environment to control shear stress and other forces is crucial for successful cell culture. By incorporating different channel geometries, flow rates, and materials, the shear forces can be adjusted to meet the needs of specific cell types and experiments.

How FLUI'DEVICE Streamlines Microfluidic Cell Culture Design

FLUI’DEVICE offers a powerful platform for designing microfluidic devices with ease and efficiency. Here’s how FLUI’DEVICE simplifies the design process:

- Intuitive Design Interface: FLUI’DEVICE allows users to drag and drop modules to design microfluidic systems without the need for complex CAD software. This user-friendly interface makes it accessible to both experienced engineers and researchers without a technical design background.

- Real-Time Simulation: FLUI’DEVICE allows you to simulate fluid flow, Reynold’s number, and other critical parameters in real time. This allows users to test different designs and optimize them before physical prototyping, saving both time and resources.

- Customizable Modules: FLUI’DEVICE offers a variety of pre-designed modules for different cell culture applications. Users can easily customize these modules to match the unique needs of their experiments, whether that involves altering channel dimensions or incorporating specific environmental factors.

Seamless Export Options: Once the design is complete, FLUI’DEVICE allows users to export their designs in various formats (e.g., STL, DXF, SVG), making it easy to send them for microfabrication.

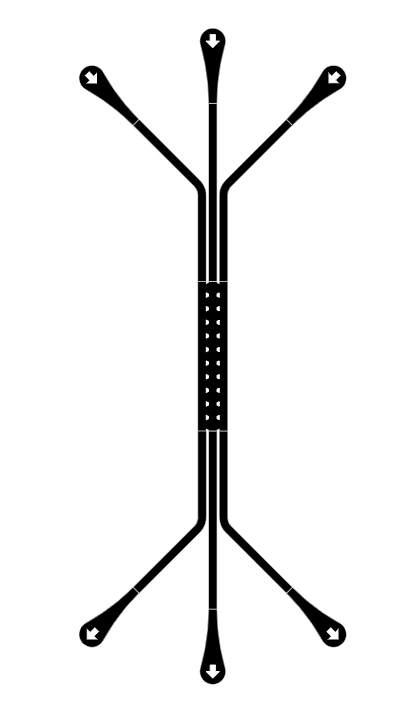

Organ-on-Chip made with FLUI’DEVICE

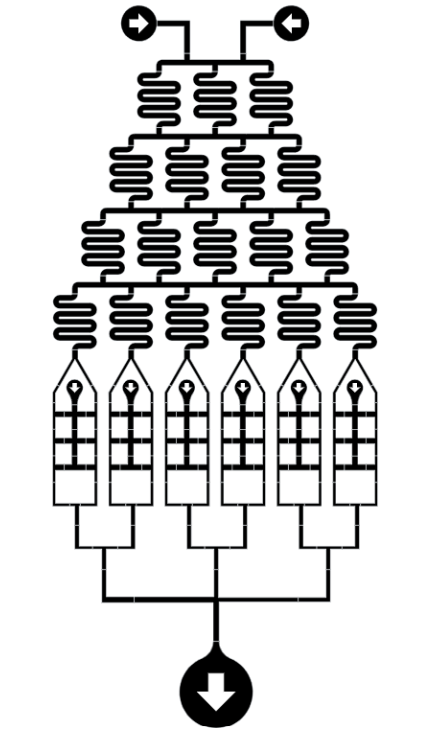

Gradient cell culture design made with FLUI’DEVICE

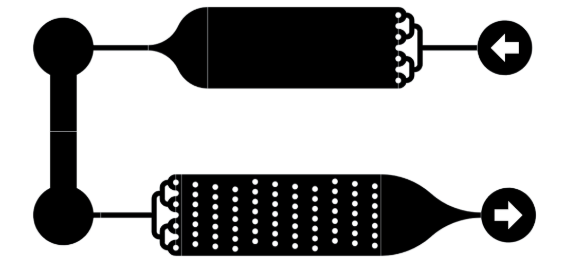

3D Cell culture chips made with FLUI’DEVICE

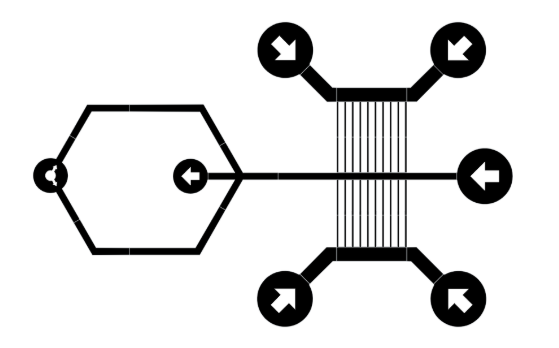

Cell culture microfluidic device made with FLUI’DEVICE

Scientific References and Citations:

- Zhang, Y., et al. (2016). “Microfluidic systems for cell culture: Advancements, applications, and future directions.” Journal of Micromechanics and Microengineering, 26(11), 113001. https://doi.org/10.1088/0960-1317/26/11/113001

- Huh, D., et al. (2010). “Microfluidic 3D cell culture for tissue-based bioengineering.” Nature, 464(7291), 217-220. https://doi.org/10.1038/nature08746

- Lin, R. Z., & Chang, H. Y. (2008). “Recent advances in three-dimensional multicellular spheroid culture for biomedical research.” Biotechnol. J., 3(9-10), 1173-1184. https://doi.org/10.1002/biot.200800073

Conclusion

Microfluidic cell culture is a rapidly advancing field that provides exceptional control over cellular environments. With the use of materials like Flexdym and design platforms like FLUI’DEVICE, researchers are empowered to create highly efficient, reproducible, and customizable cell culture systems. Whether you are exploring new drug therapies or studying cellular behavior, microfluidic cell culture platforms can revolutionize the way we conduct biomedical research.