Use of Flexdym in Skin-Interfaced Sweat Microfluidic Devices Case Study

Overview: This case study highlights the innovative application of Flexdym, a thermoplastic elastomer (TPS), in developing skin-interfaced sweat microfluidic devices. Flexdym was selected for its unique properties that enhance the functionality and reliability of these devices, particularly in the context of wireless, skin-interfaced electronic systems. Indeed, TPEs are soft, flexible, and biocompatible and these devices can adhere to the skin without irritating and are capable of wireless communication.

Material Selection and Surface Modification: Flexdym’s favorable characteristics such as rapid processability, optical transparency, and compatibility with microfluidic applications made it an ideal candidate for this project. Additionally, the possibility of creating a capillary pump with Flexdym discussed in the paper by Lachaux et al1 plays a crucial role in developing flexible microfluidic skin patches.

The capillary pump’s efficient fluid management, passive operation, and reliable filling behavior are key features that enable its integration into wearable devices like the skin patch. The Flexdym material ensures consistent and smooth fluid flow through microchannels while maintaining structural integrity and flexibility, which are essential for skin contact applications. This makes Flexdym an ideal material for creating self-contained, portable, and biocompatible microfluidic systems suitable for biological assays and point-of-care diagnostics.

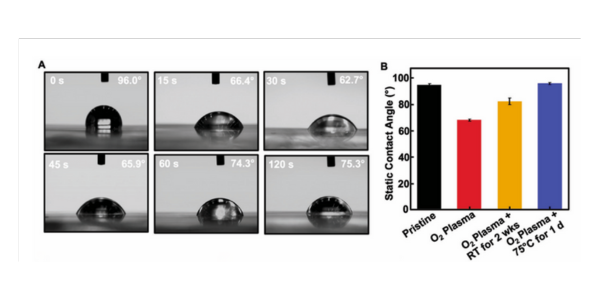

To further optimize Flexdym for sweat microfluidic devices, surface modifications, including O2 plasma treatment, were conducted. These treatments significantly reduced the static water contact angle (WCA), improving the hydrophilicity of the material, which is crucial for microfluidic operations.

Mechanical Properties: The mechanical characterization of Flexdym revealed its softness (E ≈2.0 MPa) and high elasticity (elongation at break ≈710%), which are comparable to PDMS, a commonly used material in similar applications. However, Flexdym’s lower sweat absorption (≈0.2% after 2 hours) and water vapor transmission rate (WVTR ≈36 g/m2/d) demonstrated its superiority over PDMS, making it more suitable for applications where accurate sweat analysis is critical.

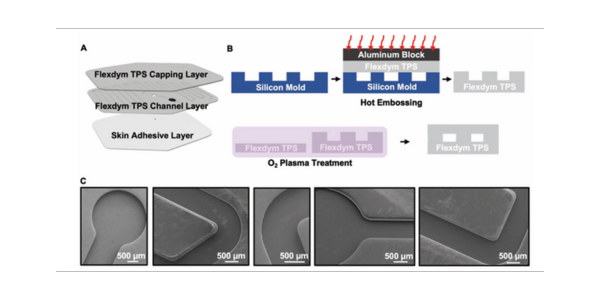

Fabrication Process: The fabrication of the sweat microfluidic device involved molding microfluidic channels and reservoirs into a Flexdym layer using a hot embossing technique. This process utilized a silicon master mold under specific conditions2 to create channels with depths of approximately 330 μm. The resulting structures were precisely replicated and met the design specifications required for efficient sweat collection and analysis.

Performance and Application: Flexdym-based devices were tested for their ability to accurately capture and retain sweat for subsequent analysis. The material’s low absorption and WVTR ensured that the sweat remained within the channels without significant loss, preventing evaporation or absorption that could lead to measurement inaccuracies. These properties are crucial for the reliable performance of skin-interfaced sweat sensors in real-world conditions. Demonstration of the Flexdym sweat microfluidic device appears in Figure 5E, where a volunteer subject, undergoing a vigorous cycling session, wears the device on their left forearm, without any observable device delamination from the skin. After 45 minutes, sweat enters and fills part of the device, reacting with the reagent and producing a light shade of purple in the resultant microchannels.

Conclusion

The application of Flexdym in skin-interfaced sweat microfluidic devices represents a significant advancement in the field of wearable electronics. Its superior mechanical properties, low sweat absorption, and effective fabrication process make it a valuable material for enhancing the accuracy and reliability of sweat-based diagnostics. The success of this project demonstrates Flexdym’s potential for broader use in various bio-integrated electronic applications.

References