Introduction to Microfluidics and Microfluidic Design

Microfluidics represents a cutting-edge domain focused on the control of fluids at a microscopic level. It finds extensive application in areas such as medical diagnostics, chemical analysis, and drug discovery research. Microfluidic design can be challenging for researchers, PhDs, or engineers.

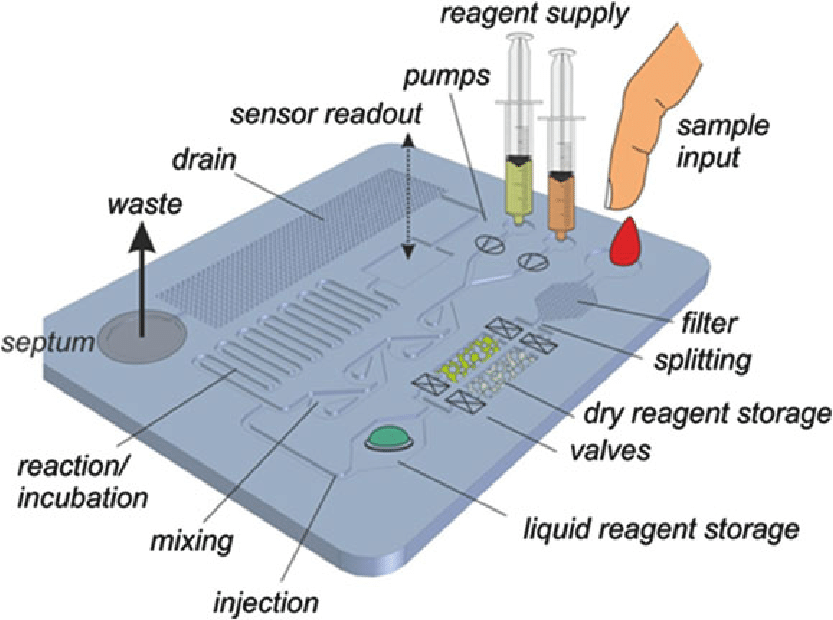

A standard microfluidic device has channels and chambers. These parts control and guide small amounts of fluid. They are often used for specific reactions or processes. In this review, we will overview how to design microfluidic devices.

Microfluidic design is crucial to ensuring the efficiency and accuracy of these devices. The design process includes making detailed microfluidic channel layouts and improving fluid flow.

It also ensures the design works well for its purpose. This could be for lab-on-a-chip devices, point-of-care diagnostics, organ-on-chip, or other special systems. As the demand for microfluidic devices grows, the need for accessible and efficient design tools becomes more evident.

Many engineers and researchers use traditional CAD (Computer-Aided Design) software. They often choose tools like Clewin, SolidWorks, or AutoCAD to create microfluidic designs. These tools work well, but they can be hard to learn. They also need a lot of time, especially for people who are not experts in CAD..

Castillo-Leon, Jaime & Svendsen, Winnie & Dimaki, Maria & Arima, Valentina & Akram, Muhammad & Miserere, Sandrine & Neumann, Christiane & Kipling, G.. (2015). Lab-on-a-Chip Devices and Micro-Total Analysis Systems A Practical Guide. 10.1007/978-3-319-08687-3.

Introducing FLUI’DEVICE: A Game-Changer in Microfluidic Design

FLUI’DEVICE changes the way we design microfluidic devices. It provides a web-based platform that makes creating these devices easier. FLUI’DEVICE has an easy-to-use interface.

It lets users design, simulate, and export microfluidic layouts quickly and affordably. Whether you are a beginner or an experienced designer, FLUI’DEVICE’s accessible features will streamline your design process and provide accurate, reliable results.

Microfluidic Device Design with FLUI’DEVICE

-

Start with a Clear Concept

Before diving into the software, it’s important to have a clear understanding of your project’s goals. Do you need a simple microfluidic device to move fluids? Or are you working on something more complex, like an organ-on-chip for 3D cell culture? Having a solid concept in mind will guide your design choices in FLUI’DEVICE.

-

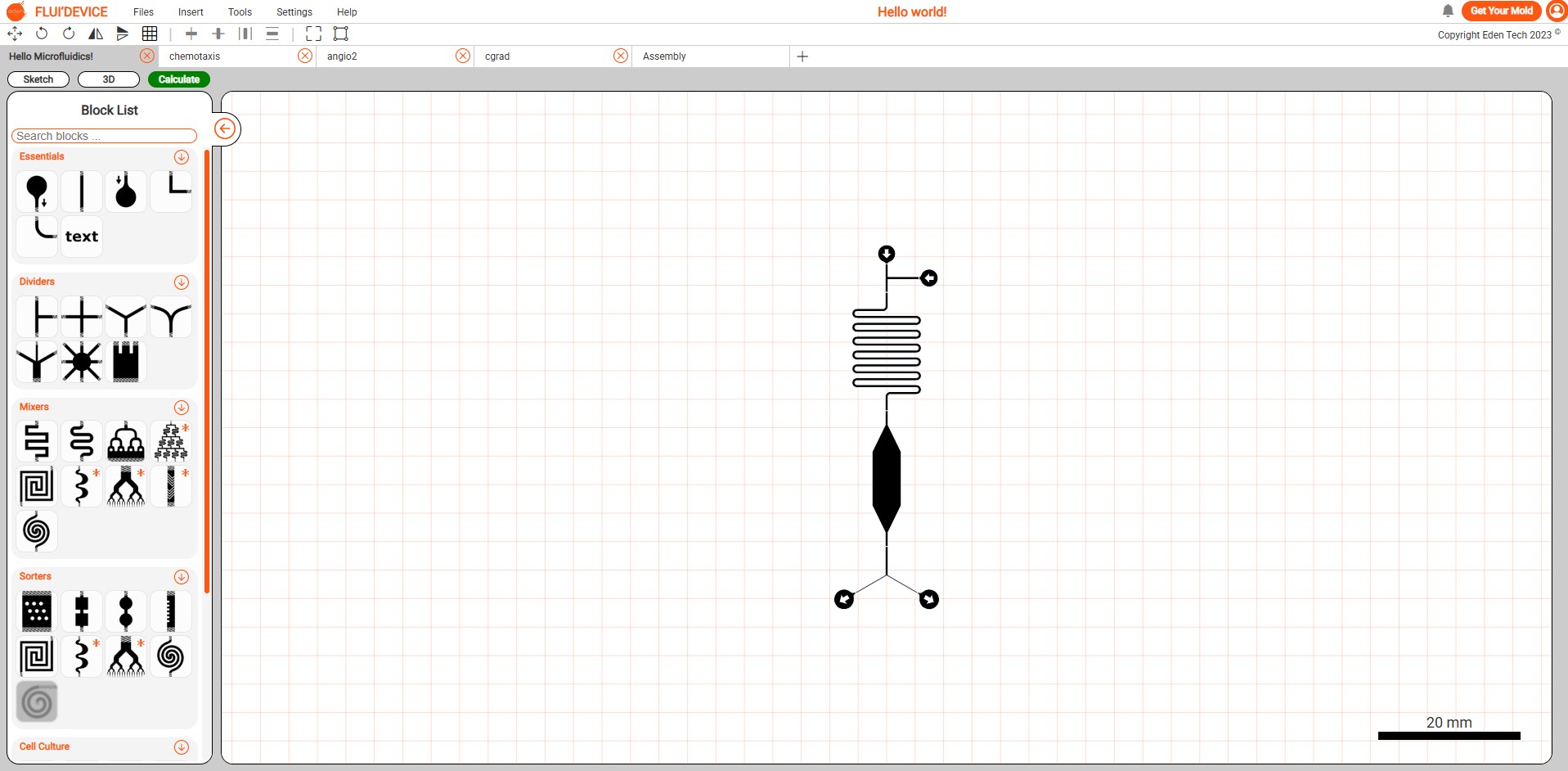

Create your microfluidic design

With FLUI’DEVICE’s drag-and-drop functionality, designing a microfluidic chip becomes effortless. Select from a wide range of pre-designed modules or create your channels, mixers, reservoirs, and more. The platform allows you to easily place elements, resize length, width, and height, and adjust them to fit your design needs.

-

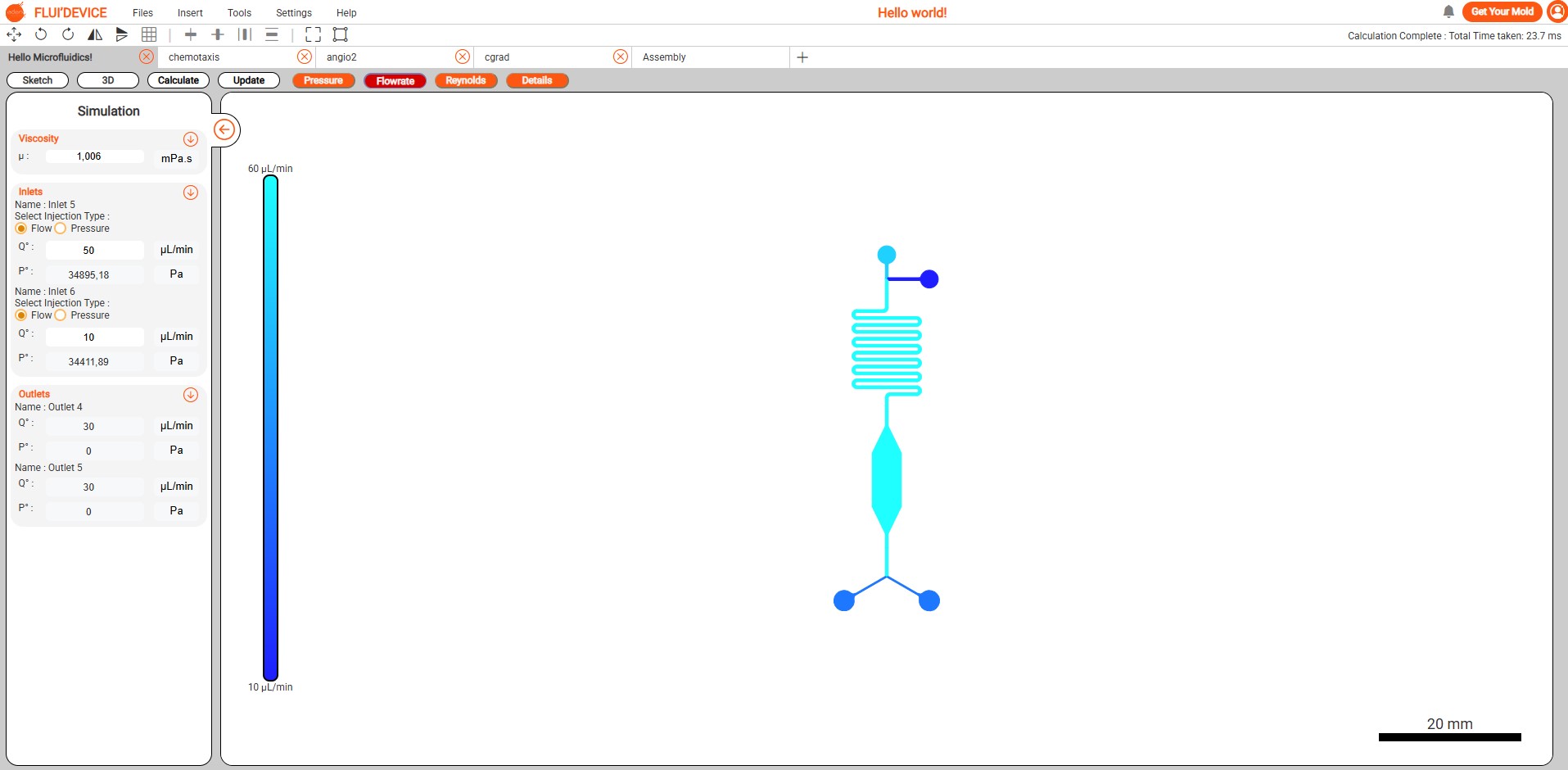

Simulate your design

One of the key features of FLUI’DEVICE is its built-in microfluidic calculator. This tool allows you to calculate important parameters such as flow rate, pressure, Reynolds number, hydraulic resistance, and more. These important insights help you evaluate and improve your design’s performance. This ensures your microfluidic device meets the needed fluid dynamics specifications.

-

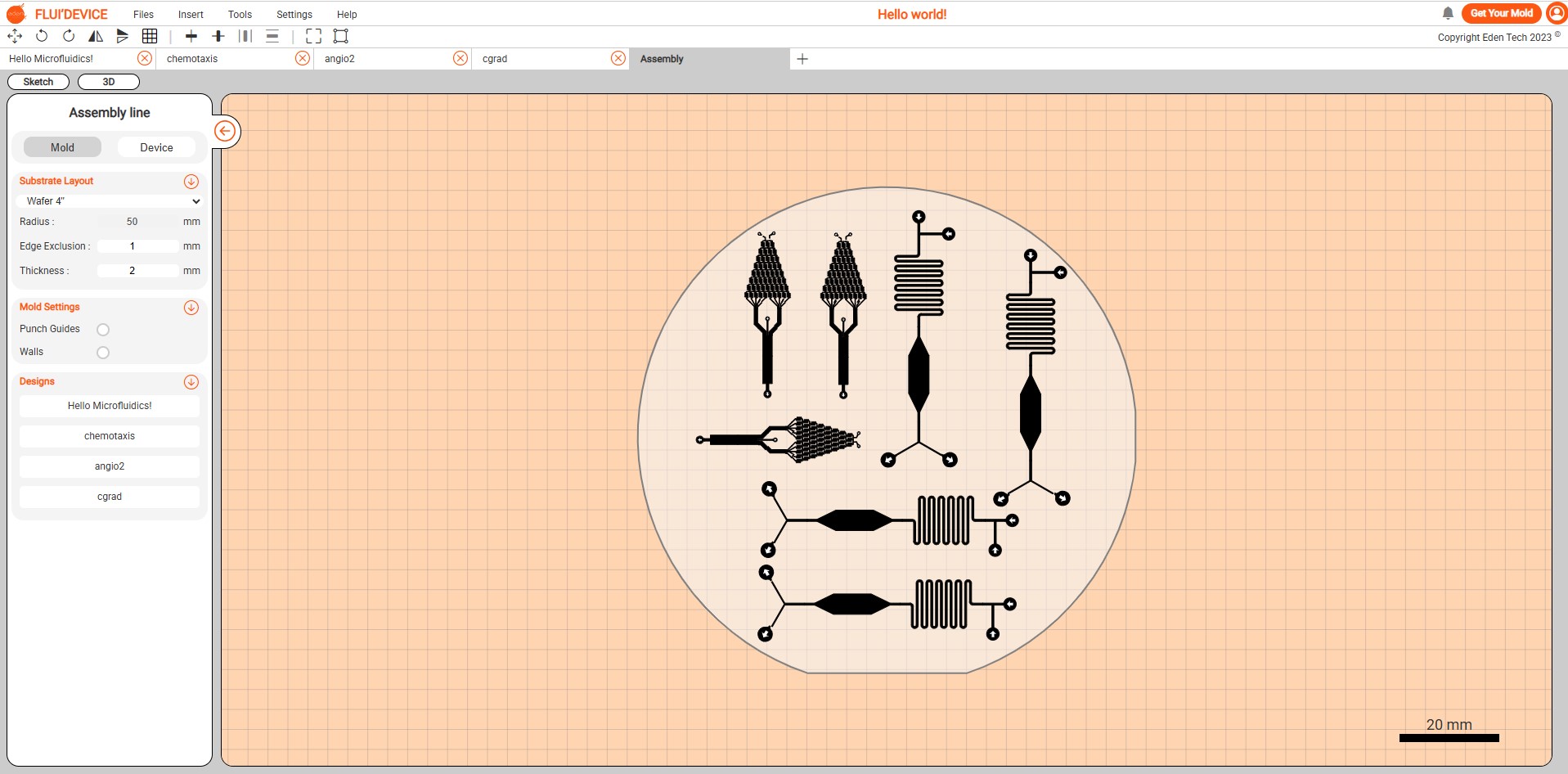

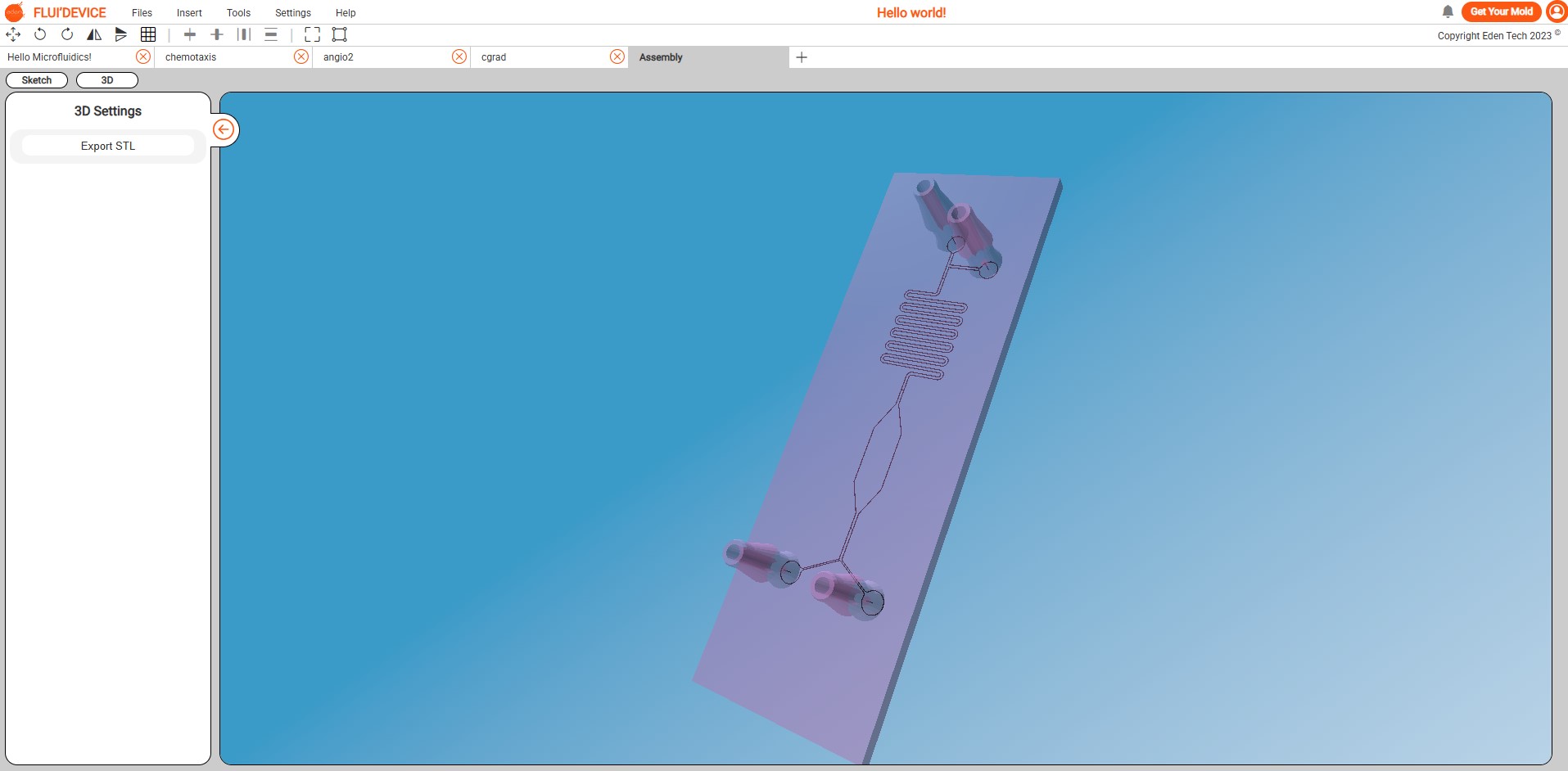

Assemble your design

Once you finish your design, FLUI’DEVICE makes assembly easier. It helps you create molds and 3D microfluidic chips. The platform allows you to design molds for standard formats such as a 4″ wafer or glass slide, or even custom sizes tailored to your needs.

FLUI’DEVICE has all the tools you need. You can use them to create a microfluidic chip for any application. You can also use them for a 3D device. They help you go from design to prototype. This flexibility ensures that your microfluidic designs can easily be translated into functional, manufacturable devices, streamlining the path from concept to production.

-

Export Your Microfluidic CAD Design

Once satisfied with your design, FLUI’DEVICE offers multiple export options. You can save your design in different file formats like SVG, STL, or DXF. This makes it easy to prepare for production or share with others. This seamless transition from design to fabrication is one of the major advantages of using FLUI’DEVICE.

Why Choose FLUI’DEVICE Over Traditional CAD Software?

Designers often use traditional CAD software, such as Clewin, SolidWorks, and AutoCAD, in microfluidic design. However, these programs need a lot of skill and time to use effectively. FLUI’DEVICE specifically tailors itself to microfluidics, making it more accessible to both experts and newcomers. Here are some reasons to consider FLUI’DEVICE for your next project:

- User-Friendly Interface: No need for specialized CAD skills. FLUI’DEVICE simplifies the design process for everyone.

- Fast and Efficient: Create, simulate, and export your designs in a fraction of the time.

- Optimized for Microfluidics: Tailored features for microfluidic design, ensuring accurate and reliable results.

- Cost-Effective: FLUI’DEVICE has a free version with many features. It also offers affordable premium options for advanced capabilities

Begin your microfluidic design journey today!

Conclusion

Designing a microfluidic device no longer must be a complicated, time-consuming task. With FLUI’DEVICE, anyone from researchers to engineers can create and simulate microfluidic devices with ease.

FLUI’DEVICE has all the tools you need. This is true whether you are working on a simple fluid channel or a complex lab-on-a-chip device. It helps you bring your project to life quickly and efficiently. Experience the future of microfluidic design today – it’s as easy as clicking a button.

Discover detailed pricing plans for FLUI’DEVICE.