Fields of

Application

- Cellular microsystems

- Disease-on-a-chip

- Organ-on-a-chip

- Cell guidance

- Cell culture

- Spheroids

MICROSYSTEMS FOR PHARMA, FROM RESEARCH TO INDUSTRY

MATERIALS FOR

CELLULAR ENGINEERING

Many researchers in Pharma and Cellular Engineering are facing challenges when they are fabricating chips.

Eden Tech offers the solutions: A biocompatible, scalable and affordable polymer, perfect for prototyping, clinical essays and mass production. It comes along with a mold replication system and a hot embossing machine.

Fields of

Application

- Cellular microsystems

- Disease-on-a-chip

- Organ-on-a-chip

- Cell guidance

- Cell culture

- Spheroid

A NEW ALTERNATIVE FOR PDMS

Are you tired of spending hours making PDMS chips?

Do you want your chip to be ready within few minutes?

Do you want to focus on your research instead of repetitive and tedious tasks?

Previous slide

Next slide

A NEW ALTERNATIVE FOR PDMS

Are you tired of spending hours making PDMS chips?

Do you want your chip to be ready within few minutes?

Do you want to focus on your research instead of repetitive and tedious tasks?

Previous slide

Next slide

Eden Tech offers

new solutions for R&D

Develop easily your microfluidic device from prototyping to production !

Flexdym is the first thermoelastic polymer designed FOR microfluidics. It offers several advantages such as:

- Room temp. bonding

- Simple protocol

- Affordable Price

- Biocompatible

Eden Tech offers new solutions for R&D

Develop easily your microfluidic device from prototyping to production !

Flexdym is the first thermoelastic polymer designed FOR microfluidics. It offers several advantages such as:

- Room Temperature Bonding

- Simple Protocol

- Affordable Price

- Biocompatible

Make your chip within 3 minutes instead of hours !

YOUR SOLUTIONS

Cellular Engineering has never been this easy !

YOUR SOLUTIONS

Discover our new microfabrication solutions for Pharma !

Flexdym is the first thermoelastic polymer designed FOR microfluidics. It offers several advantages such as:

WHY FLEXDYM ?

LOW ABSORPTION

RECYCLABLE MATERIAL

CERTIFIED BIOCOMPATIBLE

PROTOTYPING TO MASS PRODUCTION

WHY FLEXDYM?

LOW ABSORPTION

RECYCLABLE MATERIAL

CERTIFIED BIOCOMPATIBLE

PROTOTYPING TO MASS PRODUCTION

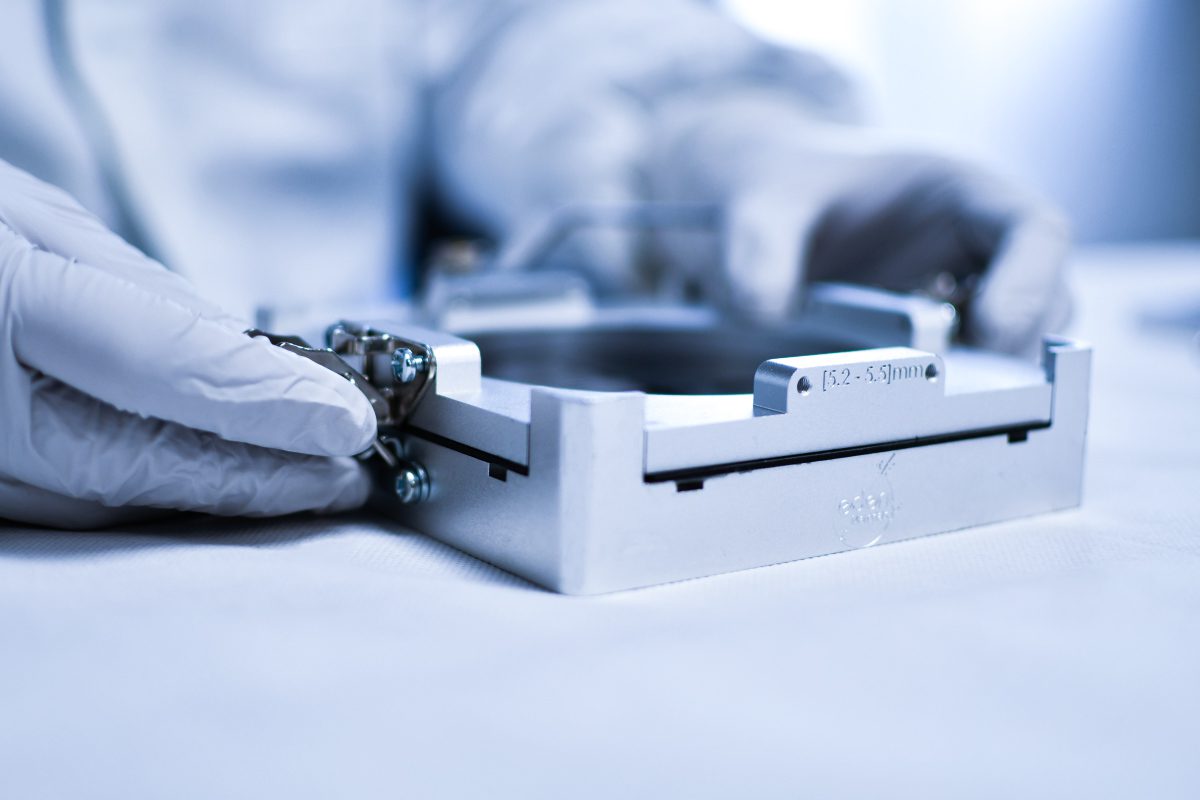

HOW TO USE FLEXDYM?

From prototyping & research to industrialization !

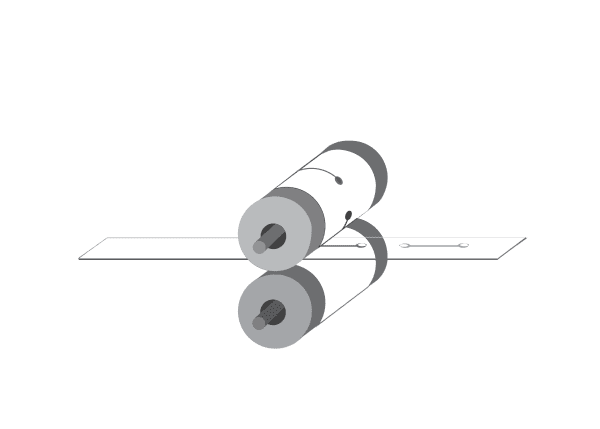

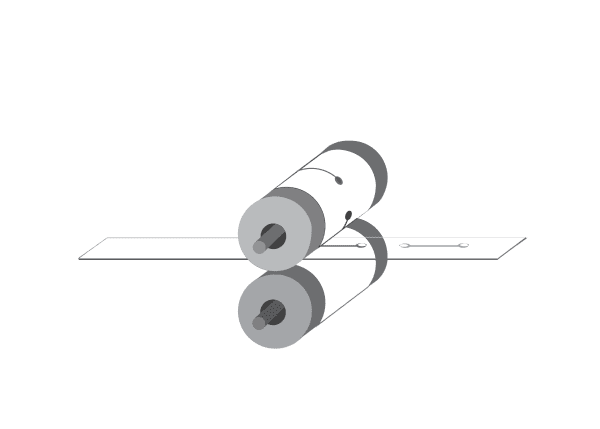

ROLL-TO-ROLL EMBOSSING

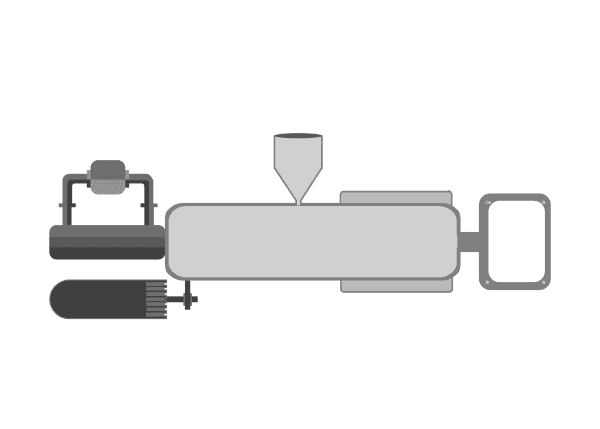

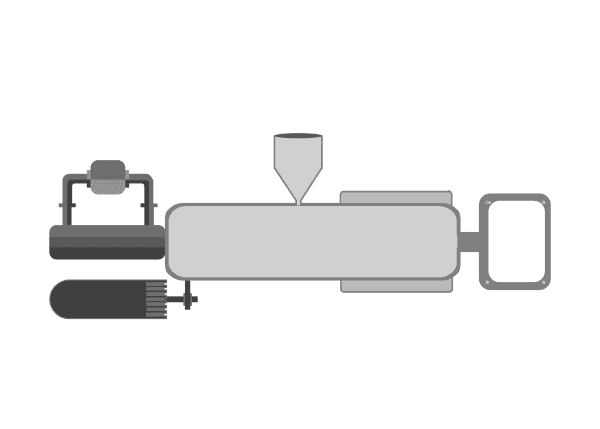

INJECTION MOLDING

SUBLYM HOT EMBOSSING

HOW TO USE FLEXDYM?

From Prototyping & Research to industrialization !

ROLL-TO-ROLL EMBOSSING

INJECTION MOLDING

SUBLYM HOT EMBOSSING

CHIP FABRICATION USING SUBLYM

STEP I

CUT FLEXDYM

Flexdym sheets are ready-to-use. Cut the Flexdym sheet to the size of your mold using a pair of scissors, or by die cut or lasers.

STEP II

SANDWICH & PRESS

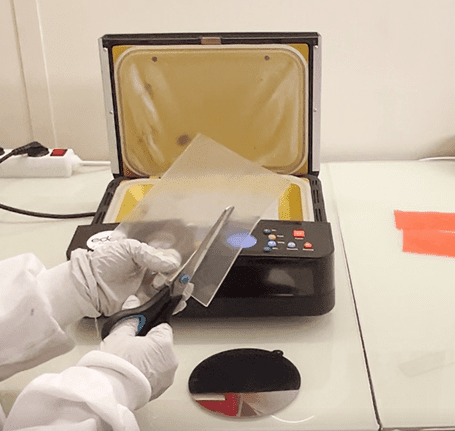

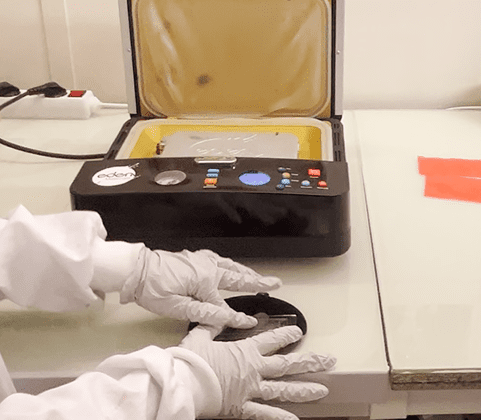

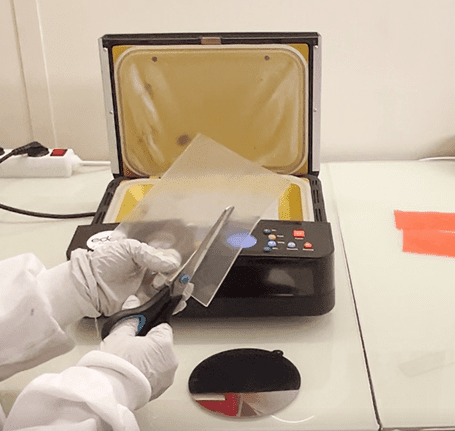

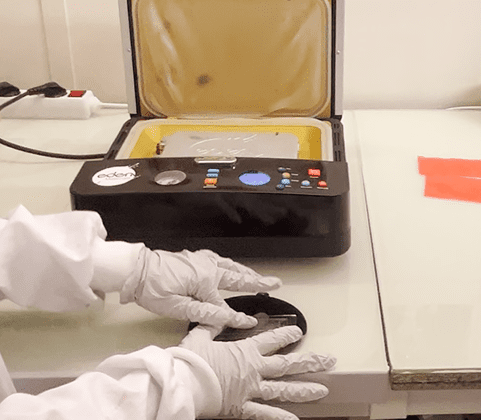

Sandwich Flexdym sheets between mold & counter mold. Place it in the Sublym hot embossing machine for about 1-3minutes.

STEP III

UNMOLD

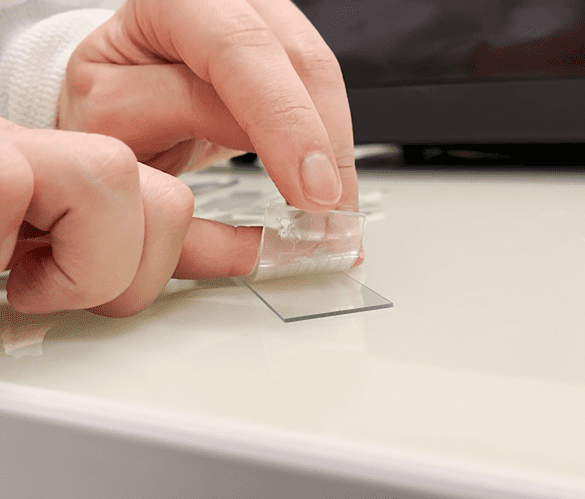

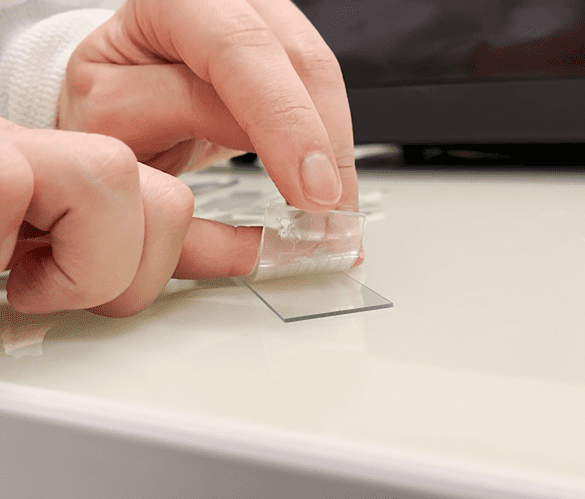

Remove pressed sandwich from machine & allow to cool until warm to the touch. Unmold with the help of isopropanol & flat tweezers.

STEP IV

ASSEMBLE

Flexdym bonds to glass, silicon & thermoplastics via good conformal contact. This can be done manually or using the Sublym.

CHIP FABRICATION USING SUBLYM HOT EMBOSSING MACHINE

CUT FLEXDYM

Flexdym sheets are ready-to-use. Cut the Flexdym sheet to the size of your mold using a pair of scissors, or by die cut or lasers.

SANDWICH & PRESS

Sandwich Flexdym sheets between mold & counter mold. Place it in the Sublym hot embossing machine for about 1-3minutes.

UNMOLD

Remove pressed sandwich from machine & allow to cool until warm to the touch. Unmold with the help of isopropanol & flat tweezers.

ASSEMBLE

Flexdym bonds to glass, silicon & thermoplastics via good conformal contact. This can be done manually or using the Sublym.

Get in touch

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply within 2 working days

Visit our office

4 Rue de Rambervillers, Paris 75012

Message Us

solutions@eden-tech-materials.com

Follow Us

The Licensee shall also mark all Products with labels containing the following language: Thermoplastic materials, Flexdym, Flexaspin, Fluoroflex, are sold under license to US patents 9,238,346 and 10,369,566 and CA patent 2,681,897 from the National Research Council Canada. Rights to use these products are limited to research uses only and are not to be used for any other purpose, such as but not limited to, commercial uses, in vitro diagnostic uses, ex vivo or in vivo therapeutic uses or any type of unauthorized applications. No other rights are conveyed. Inquiry into the availability of a license to broader rights or the use of these thermoplastic materials for commercial purposes should be directed to National Research Council Canada. Purchase of these products does not grant rights to (1) offer the products or any derivatives thereof for resale; or (2) to distribute or transfer the products or any derivative thereof to third parties. Trademark Flexdym and Sublym - EU.IP Offices.