Flexdym Roll™ – Microfluidic Device Development

Want to boost your microfluidic device development with a scalable and cost-effective alternative to PDMS?

The Flexdym™ is the new biocompatible alternative to PDMS specifically created for the scale up of microfluidic devices and microfluidic device development, in both academia or industry. Flexdym is ideal for biological applications, such as organ-on-chip and point of care diagnostics, because it is certified biocompatible. More specifically, Flexdym™ is certified ISO 10993 (parts 4, 5, 6, 10, 11) and UPS Class VI, tested for toxicity and can be used for medical applications. Other advantages of Flexdym™ include optical transparency, low molecular sorption properties and reduced gas permeability.

Flexdym is a block co-polymer that combines the best properties of PDMS and thermoplastics. With Flexdym™ device replication is done in minutes and device assembly is a no treatment process. Flexdym™ bonds to a variety of substrates including COC, COP, PS, PC, PMMA, and PDMS. But the bonding strength varies according to the substrate, providing the option between reversible and permanent bonding (see table below). For this reason, Flexdym™ is an excellent option for wearable devices, flexible electronics, or reversible sealing of microfluidic cartridges.

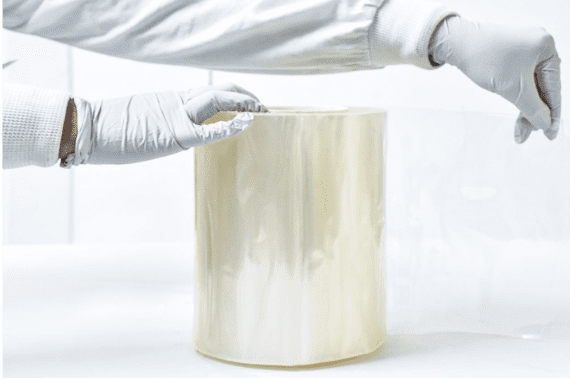

The Flexdym™ rolls are the perfect format for users who need a more cost-effective option after testing our starter pack, but it is also compatible with roll-to-roll embossing methods of mass production. Here, the price per device decreases dramatically, as the roll length increases.

If you are interested in first testing out the Flexdym polymer, check out our Flexdym™ Starter Pack. But if you are interested in Flexdym™ for injection molding mass production or 3D printing, you should see our Flexdym™ Pellets.

And make sure to follow us on Linkedin and watch Flexdym™ tutorials on our youtube channel!