Are you looking for an alternative to PDMS soft-lithography for your microfluidics applications? The Flexdym™ polymer is the best alternative to PDMS and the first material specifically tailored for microfluidics chip fabrication. Why? Because most materials used in microfluidics have been repurpose from microelectronics and may not possess the best properties for biomedical applications. On contrast, Flexdym™ was developed and patented by our CEO and founder Emmanuel Roy specifically for biotechnology, while he worked at the CNRC (Canadian National Research Council) developing a point of care diagnostics device.

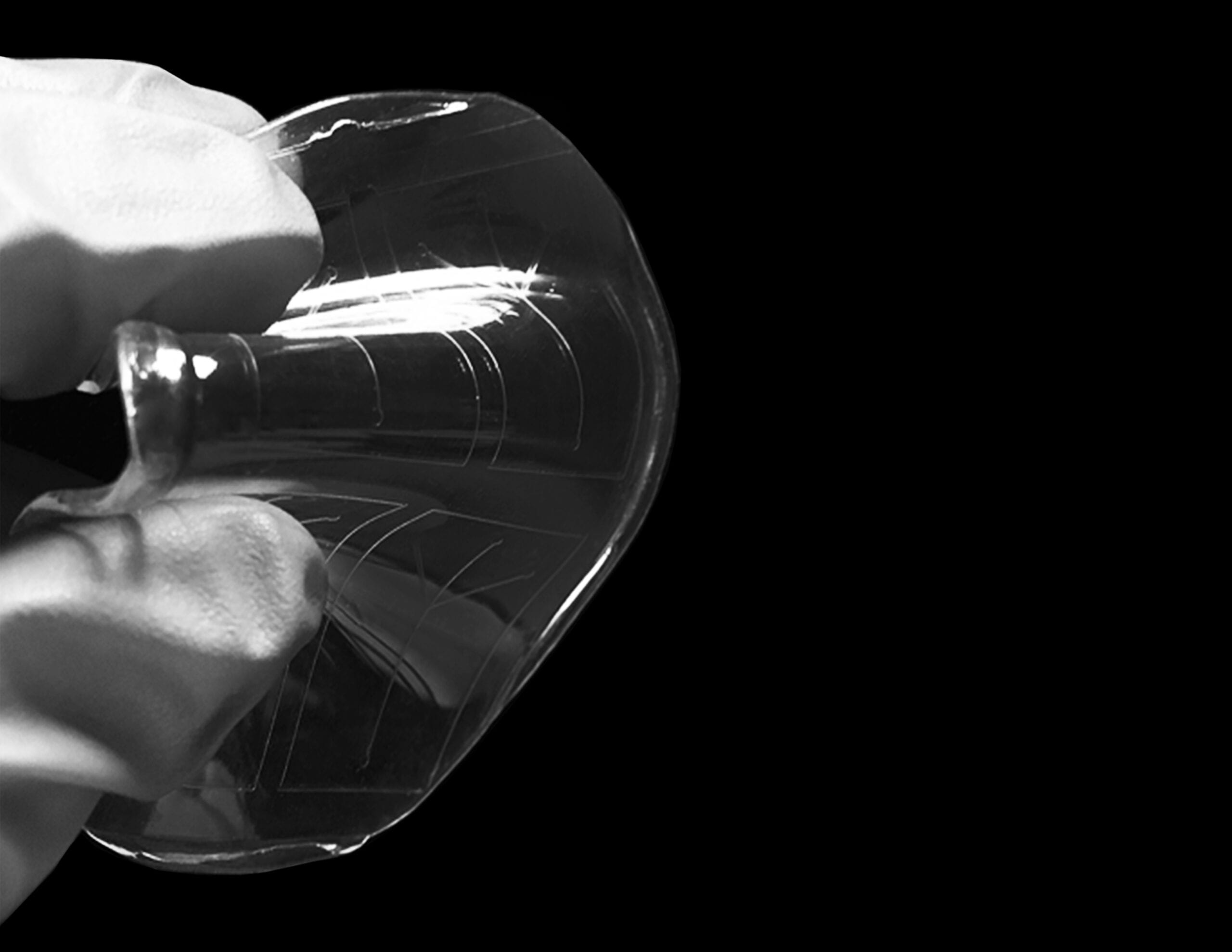

Therefore, Flexdym™ possesses the key material properties required for microfluidic biotech applications. Firstly, Flexdym™ is certified biocompatible according to international codes ISO 10993 (parts 4, 5, 6, 10, 11) and UPS Class VI. So that you can use it for the most important biological applications, such as organ-on-chip and point of care diagnostics. But this wouldn’t be enough. So we also made sure Flexdym™ has optical transparency, low molecular sorption properties and reduced gas permeability.

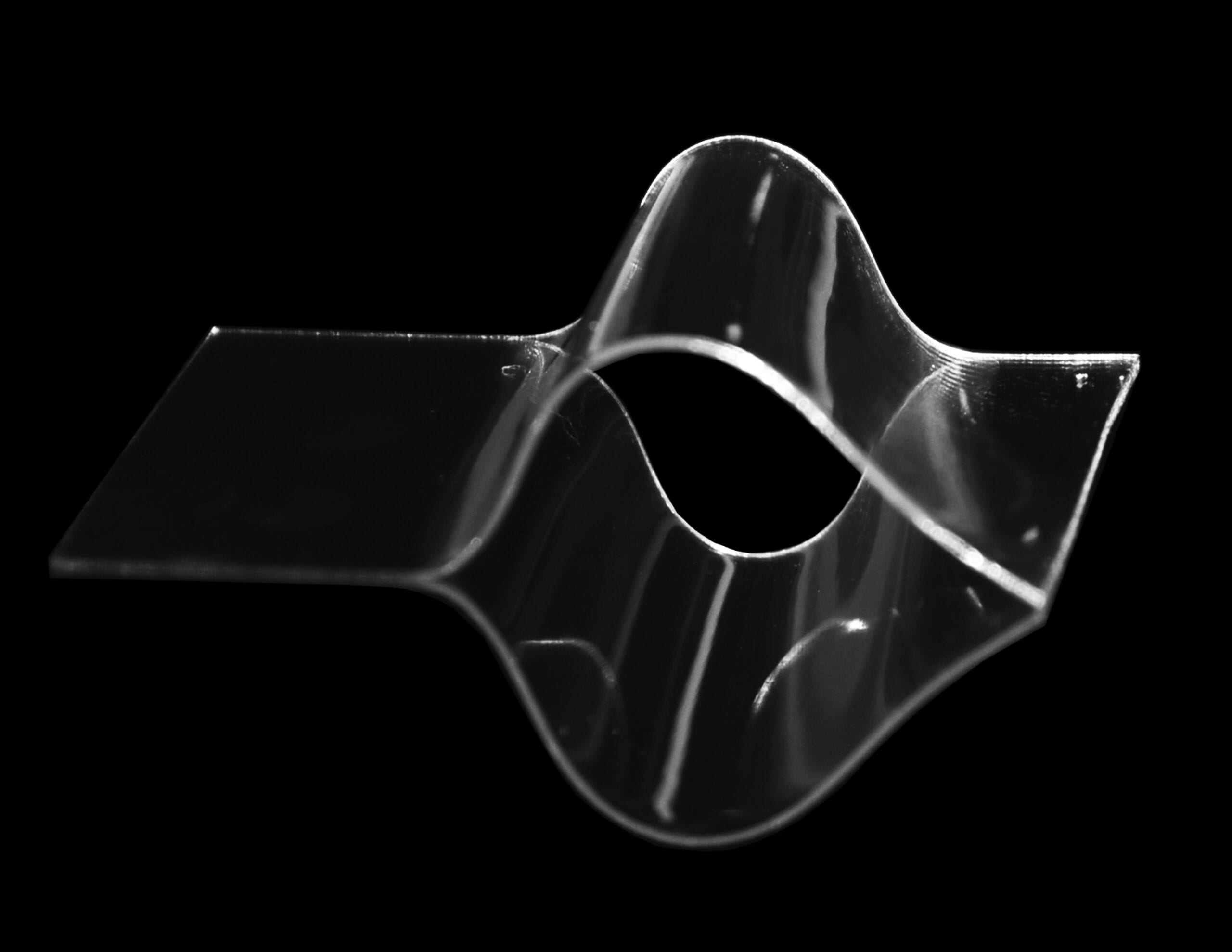

Flexdym™ is a block co-polymer that combines the best of elastomers (e.g. PDMS) and thermoplastics. Read our latest blog article describing the chemical composition of Flexdym and the bonding mechanisms which make it so fast and easy to assemble Flexdym™ devices. Flexdym™ can bond to a variety of substrates including glass, silicon, COC, COP, PS, PC, and PMMA. This provides a large range of versatility, according to the application at hand. The bonding strength varies according to the substrate (see table below), providing the option over reversible and permanent bonding. For this reason, Flexdym™ serves as an excellent option for wearable microfluidic devices, or for reversible sealing of microfluidic cartridges.

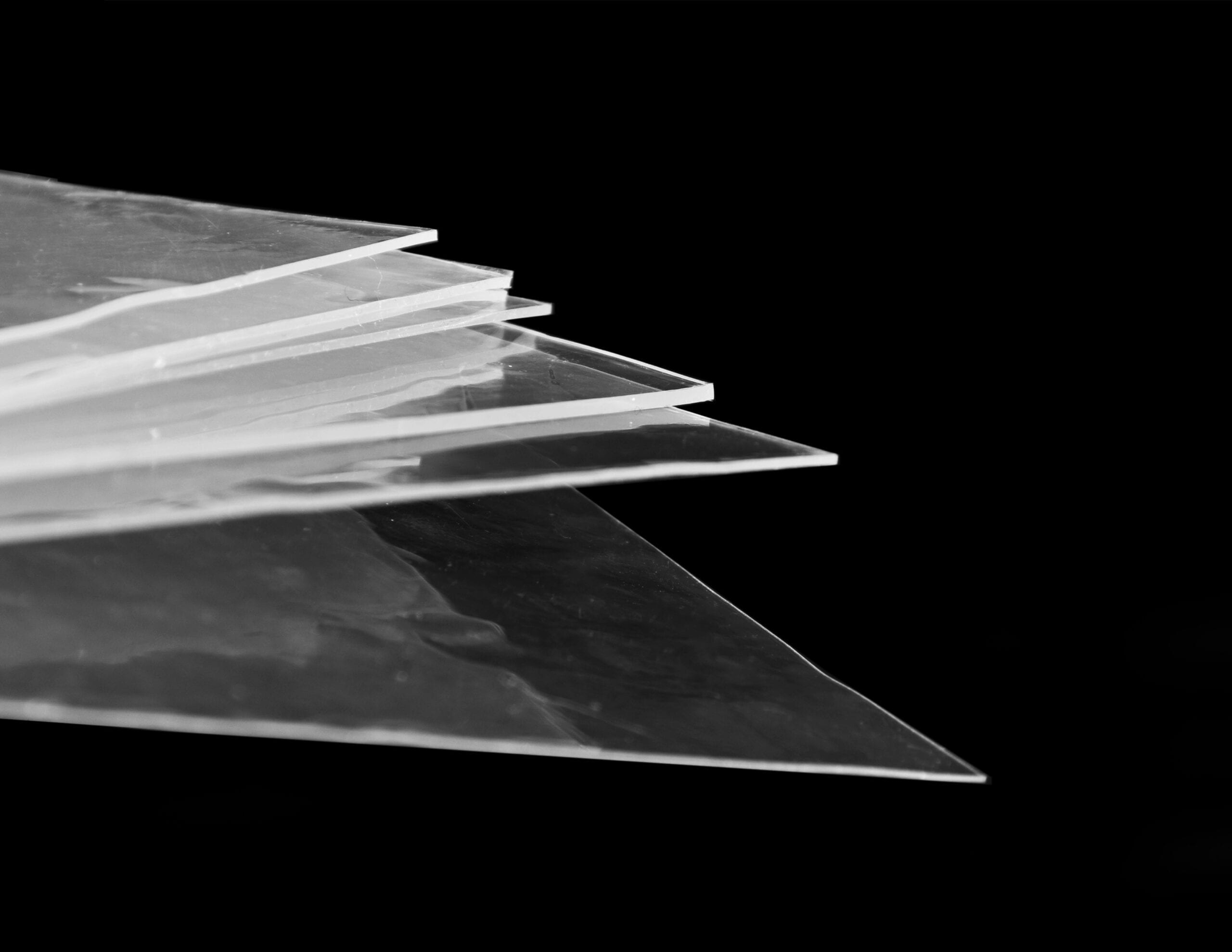

Another major advantage of Flexdym™ as an alternative to PDMS, is that it can be used in the scale up of microfluidics devices for commercial or industrial purposes. The starter pack is the perfect format for first-time Flexdym users to test the material for their application. In one starter pack different thicknesses can be mixed, making the selection process easier for you! Once you have discovered your thickness of choice, the next step is to scale-up with our more cost effective formats, linked here: Flexdym™ Rolls or Flexdym™ Pellets.

Remember you can follow Eden Tech on Linkedin and Youtube for all the latest Flexdym™ news!