SOFT LITHOGRAPHY

SCALE-UP KIT

Microfluidics Made Easy At All Production Scales.

SOFT LITHOGRAPHY SCALE-UP KIT

Microfluidics Made Easy At All Production Scales.

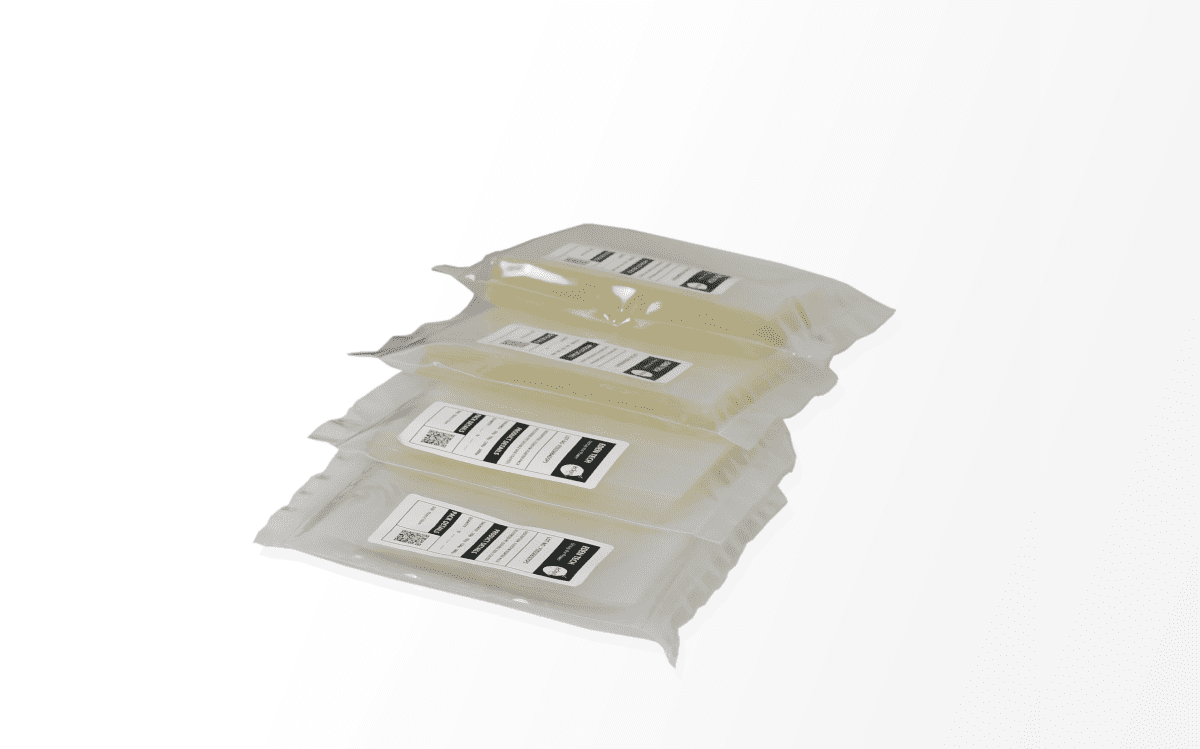

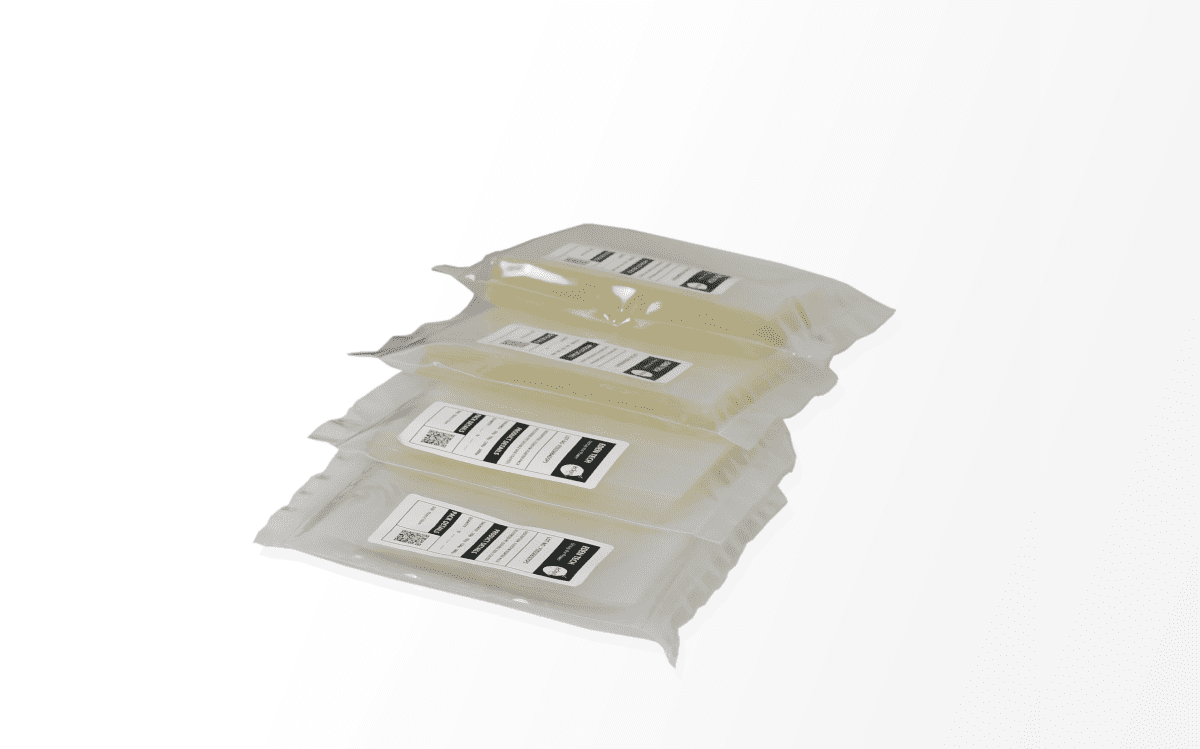

What does the kit contain?

Your first stop towards successful point-of-care microfluidic device scale-up.

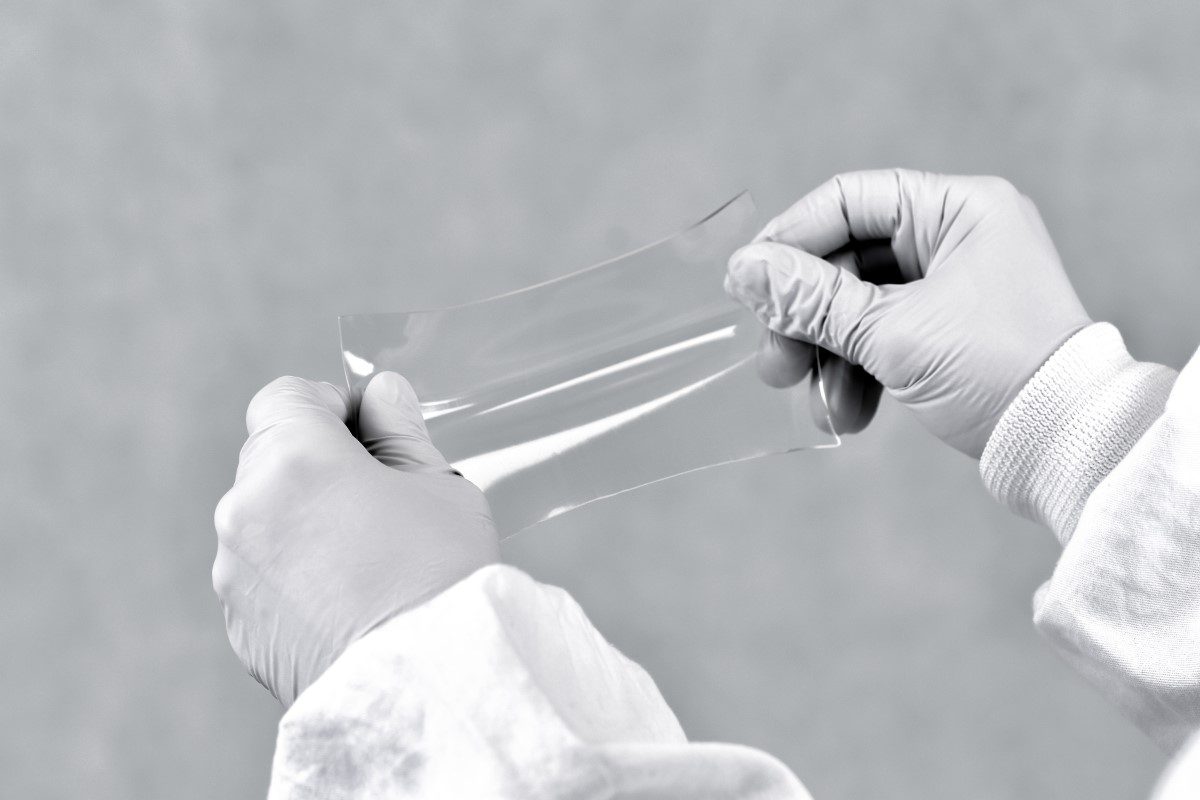

FLEXDYM

The Flexdym is the first biocompatible polymer which is also compatible with all scales of microfluidic device production.

SUBLYM

The Sublym hot embossing machine provides efficient device replication & device assembly. It is affordable, portable & user-friendly.

EPOXYM

The Epoxym mold solution replicates expensive & fragile SU8 silicon wafers into robust epoxy resin molds, for routine device replication.

CONNECTOR

Chip-to-world connection is an important component of device development. For this we provide luer adaptors or olive adaptors.

PUNCHER

The final component of the kit are metal puncher for the creation of inlet and outlet ports, responsible for introduction of reagents & removal of waste.

What does the kit contain?

Your first stop towards successful point-of-care microfluidic device scale-up.

FLEXDYM

The Flexdym is the first biocompatible polymer which is also compatible with all scales of microfluidic device production.

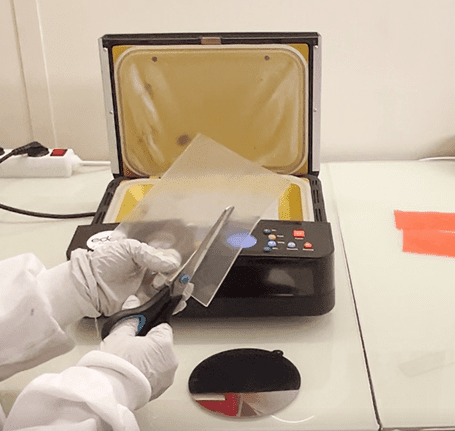

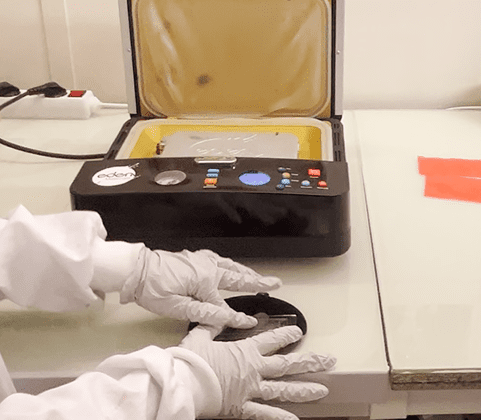

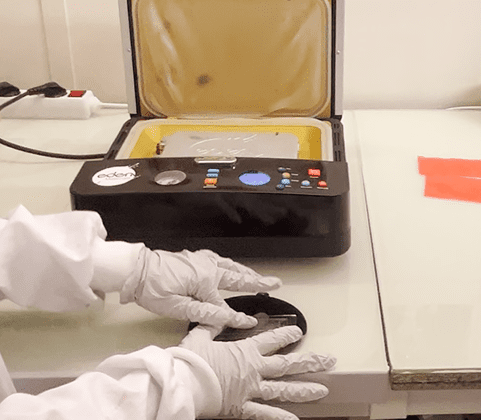

SUBLYM

The Sublym hot embossing machine provides efficient device replication & device assembly. It is affordable, portable & user-friendly.

EPOXYM

The Epoxym mold solution replicates expensive & fragile SU8 silicon wafers into robust epoxy resin molds, for routine device replication.

CONNECTOR

Chip-to-world connection is an important component of device development. For this we provide Luer adaptors or olive adaptors.

PUNCHER

The final component of the kit are metal puncher for the creation of inlet and outlet ports, responsible for introduction of reagents & removal of waste.

Flexdym for Point-of-Care applications

Key Flexdym advantages to bear in mind for point-of-care microfluidic device scale-up

Low Adsorption

Experimental results using rhodamine dye & drug reveal a lower absorption of small hydrophobic molecules.

Resistance to Thermocycling

Flexdym can sustain service temperatures of 95°C for 1hr with no leakage or channel damage.

Recycleable Material

Flexdym is a oil-free, additive-free SEBS that can be sterilized (e.g. UV, gamma, autoclave ) & recycled.

Certified Biocomptability

Flexdym is certified ISO 10993 parts 4, 5, 6, 10 & 11. Tested for cytotoxicity, implantation, system toxicity...

Flexdym Point-of-Care Device Fabrication

The Point-of-care Scale-Up Kit makes device fabrication, from initial prototyping stages to medium production scales, easy…

3Minute Replication

Our Sublym hot embossing machine can mold Flexdym in as little as 1 minute!

3 Minute Assembly

Using Sublym, assembling Flexdym devices is treatment free, easy & standardized.

1 Hour Bonding

Bonding of Flexdym devices takes as little as 1 hour, with the need for harsh treatments.

FLEXDYM POINT-OF-CARE DEVICE FABRICATION

Soft lithography microfluidic device fabrication from initial prototyping stages to medium production scales, is easy…

FLEXDYM POINT-OF-CARE DEVICE FABRICATION

Point-of-care microfluidic device fabrication from initial prototyping stages to medium production scales, is easy…

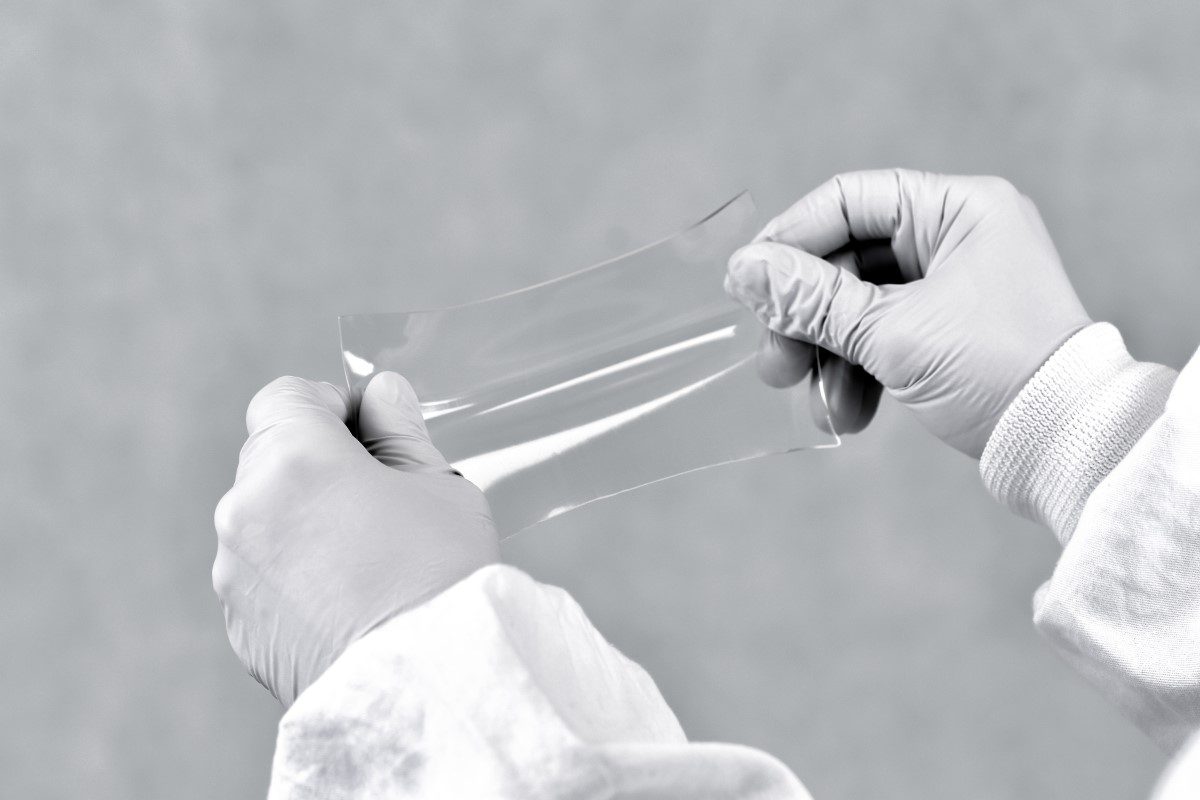

CUT FLEXDYM

Flexdym sheets are ready to use. Cut the Flexdym sheet to the size of your mold using a pair of scissors, or by die cut or lasers.

SANDWICH & PRESS

Sandwich Flexdym sheets between mold & counter mold. Place it in the Sublym hot embossing machine for about 1-3 minutes.

UNMOLD

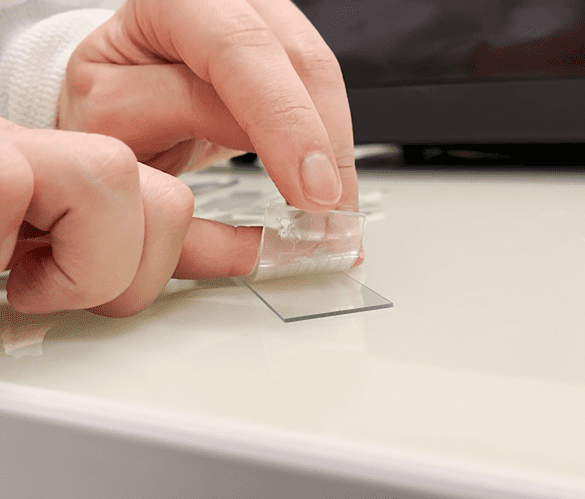

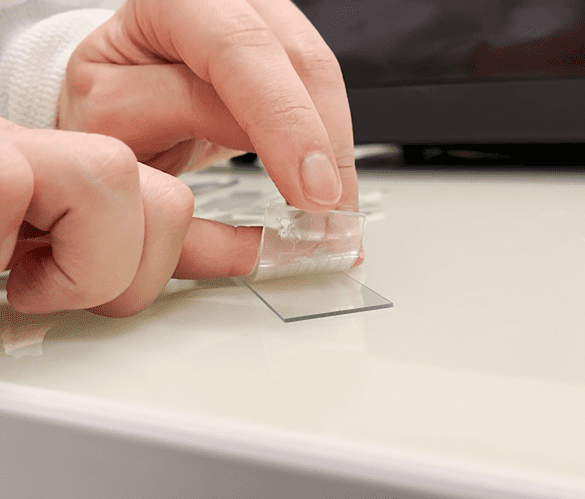

Remove pressed sandwich from machine & allow to cool until warm to the touch. Unmold with the help of isopropanol & flat tweezers.

ASSEMBLE

Flexdym bonds to glass, silicon & thermoplastics vie good conformal contact. This can be done manually or using the Sublym.

CUT FLEXDYM

Flexdym sheets are ready to use. Cut the Flexdym sheet to the size of your mold using a pair of scissors, or by die cut or lasers.

SANDWICH & PRESS

Sandwich Flexdym sheets between mold & counter mold. Place it in the Sublym hot embossing machine for about 1-3 minutes.

UNMOLD

Remove pressed sandwich from machine & allow to cool until warm to the touch. Unmold with the help of isopropanol & flat tweezers.

ASSEMBLE

Flexdym bonds to glass, silicon & thermoplastics vie good conformal contact. This can be done manually or using the Sublym.

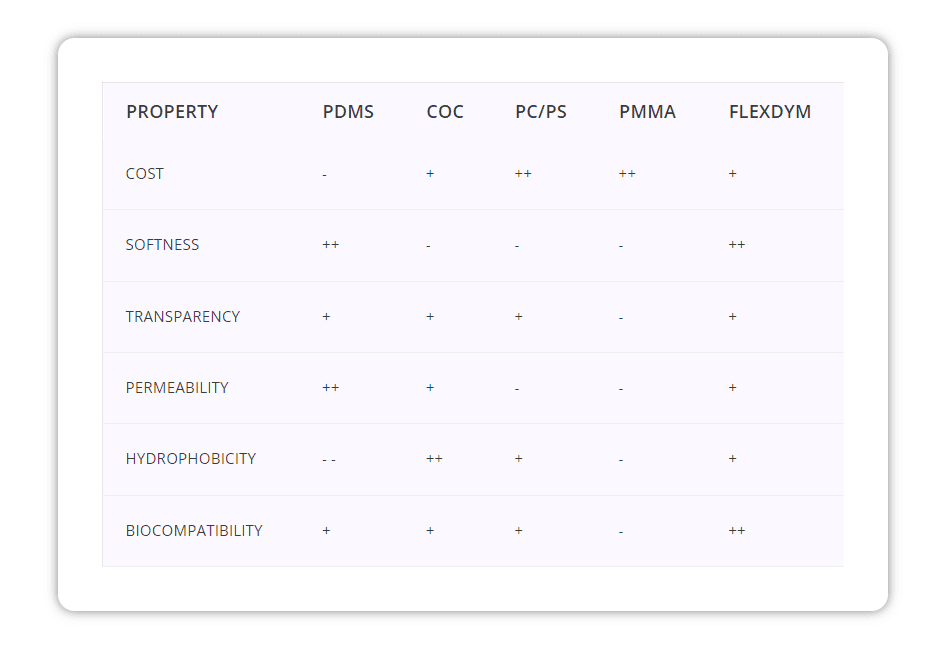

MATERIAL PROPERTIES

Comparison of Flexdym vs. other polymers commonly used in microfluidics device fabrication. Request our Material Properties brochure for more insight into the advantages of Flexdym.

| PROPERTY | PDMS | COC | PC/PS | PMMA | FLEXDYM |

|---|---|---|---|---|---|

| COST | - | + | ++ | ++ | + |

| SOFTNESS | ++ | - | - | - | ++ |

| TRANSPARENCY | + | + | + | - | + |

| PERMEABILITY | ++ | + | - | - | + |

| HYDROPHOBICITY | - - | ++ | + | - | + |

| BIOCOMPATIBILITY | + | + | + | - | ++ |

“+” is a positive atribute; “-” is a negative atribute.

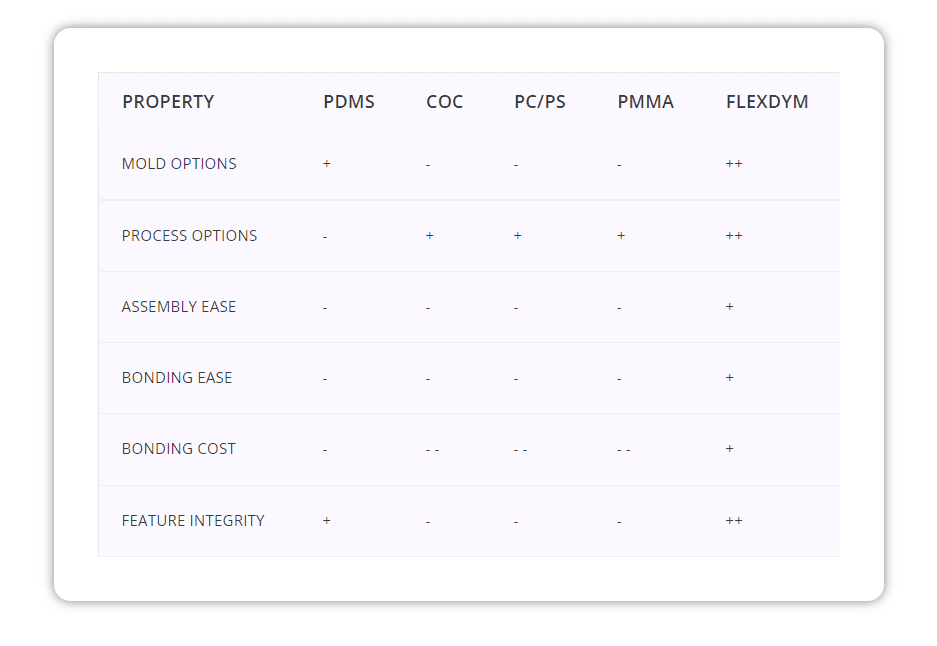

| PROPERTY | PDMS | COC | PC/PS | PMMA | FLEXDYM |

|---|---|---|---|---|---|

| MOLD OPTIONS | + | - | - | - | ++ |

| PROCESS OPTIONS | - | + | + | + | ++ |

| ASSEMBLY EASE | - | - | - | - | + |

| BONDING EASE | - | - | - | - | + |

| BONDING COST | - | - - | - - | - - | + |

| FEATURE INTEGRITY | + | - | - | - | ++ |

“+” is a positive atribute; “-” is a negative atribute.

MATERIAL PROCESSING

Comparison of Flexdym vs. other polymers, interms of ease-of-use in microfluidic device fabrication at different scales of production. Request our Material Processing brochure for more insight into these advantages of Flexdym.

MATERIAL PROPERTIES

Comparison of Flexdym vs. other polymers commonly used in microfluidics device fabrication. Request our Material Properties brochure for more insight into the advantages of Flexdym.

“+” is a positive atribute; “-” is a negative atribute.

MATERIAL PROCESSING

Comparison of Flexdym vs. other polymers, interms of ease-of-use in microfluidic device fabrication at different scales of production. Request our Material Processing brochure for more insight into these advantages of Flexdym.

“+” is a positive atribute; “-” is a negative atribute.

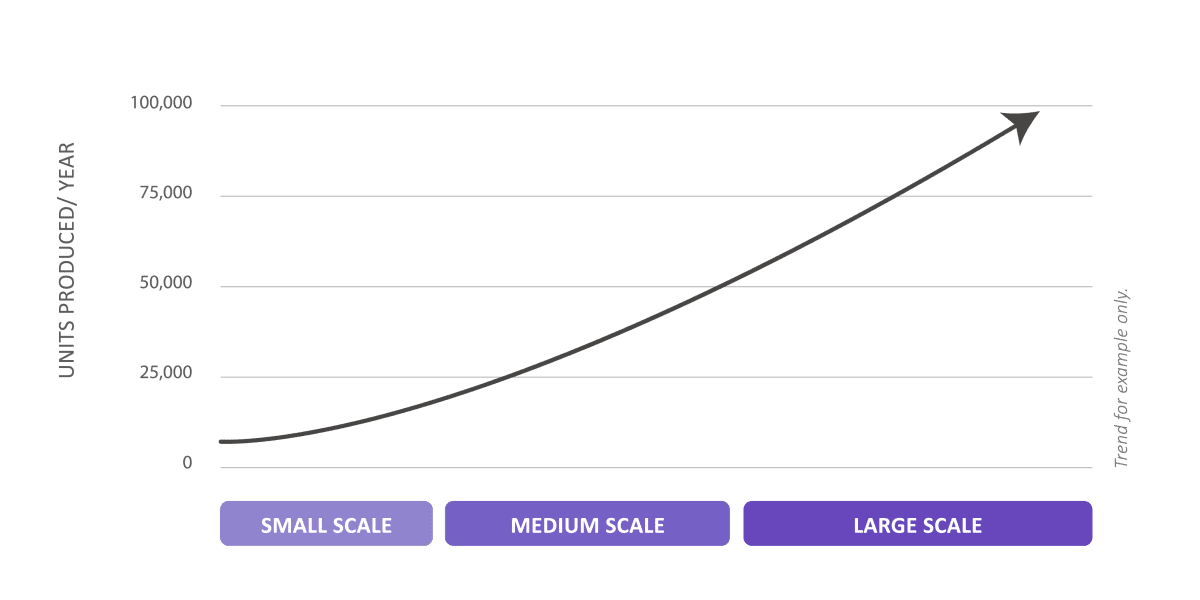

FLEXDYM AT DIFFERENT SCALES

Find out how you can scale-up with Flexdym through all scales of microfluidic device production. Key elements to consider for microfluidic device production scale-up are material costs, process costs, equipment costs, & labor costs.

Soft lithography Scale-up kit only requires a small initial investment. It covers everything from mold replication, to device replication, assembly, bonding and connection. By working with a scalable material from the beginning, you can ensure a smooth transition into large production scales.

Here, manual production lines are usually used for microfluidic device production. The Soft lithography Scale-Up Kit can still be used, but with a recommended switch Flexdym the Flexdym starter pack to Flexdym rolls (20 to 90 meters long). Device replication & assembly is performed using the Sublym embossing machine & Epoxym resin mold, or through roll-to-roll embossing.

At these scales, semi-automated lines, and even fully automated are used for the production of over 1 Million microfluidic devices/ year. We recommend the use of Flexdym rolls combined with roll-to-roll embossing, or Flexdym pellets combined with injection molding & metallic mold inserts.

HOW KIT SHIPPING WORK

Order

The product is available to pre-order at four week time increments.

Production

After this time, the orders will start to be produced during a two week period, and new orders will be added to the same shipment while stock is available.

Shipment

At this stage, items are shipped, usually taking a few working days to arrive, depending on client location.

Eden Tech

Eden Tech

The Licensee shall also mark all Products with labels containing the following language: Thermoplastic materials, Flexdym, Flexaspin, Fluoroflex, are sold under license to US patents 9,238,346 and 10,369,566 and CA patent 2,681,897 from the National Research Council Canada. Rights to use these products are limited to research uses only and are not to be used for any other purpose, such as but not limited to, commercial uses, in vitro diagnostic uses, ex vivo or in vivo therapeutic uses or any type of unauthorized applications. No other rights are conveyed. Inquiry into the availability of a license to broader rights or the use of these thermoplastic materials for commercial purposes should be directed to National Research Council Canada. Purchase of these products does not grant rights to (1) offer the products or any derivatives thereof for resale; or (2) to distribute or transfer the products or any derivative thereof to third parties.

Trademark Flexdym and Sublym – EU.IP Offices.